Industrial robot collision detection method

An industrial robot, collision detection technology, applied in manipulators, manufacturing tools, etc., can solve problems such as false alarms, different responses of servo systems, and reduce collision detection sensitivity, and achieve the effect of simple and effective methods and improved sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

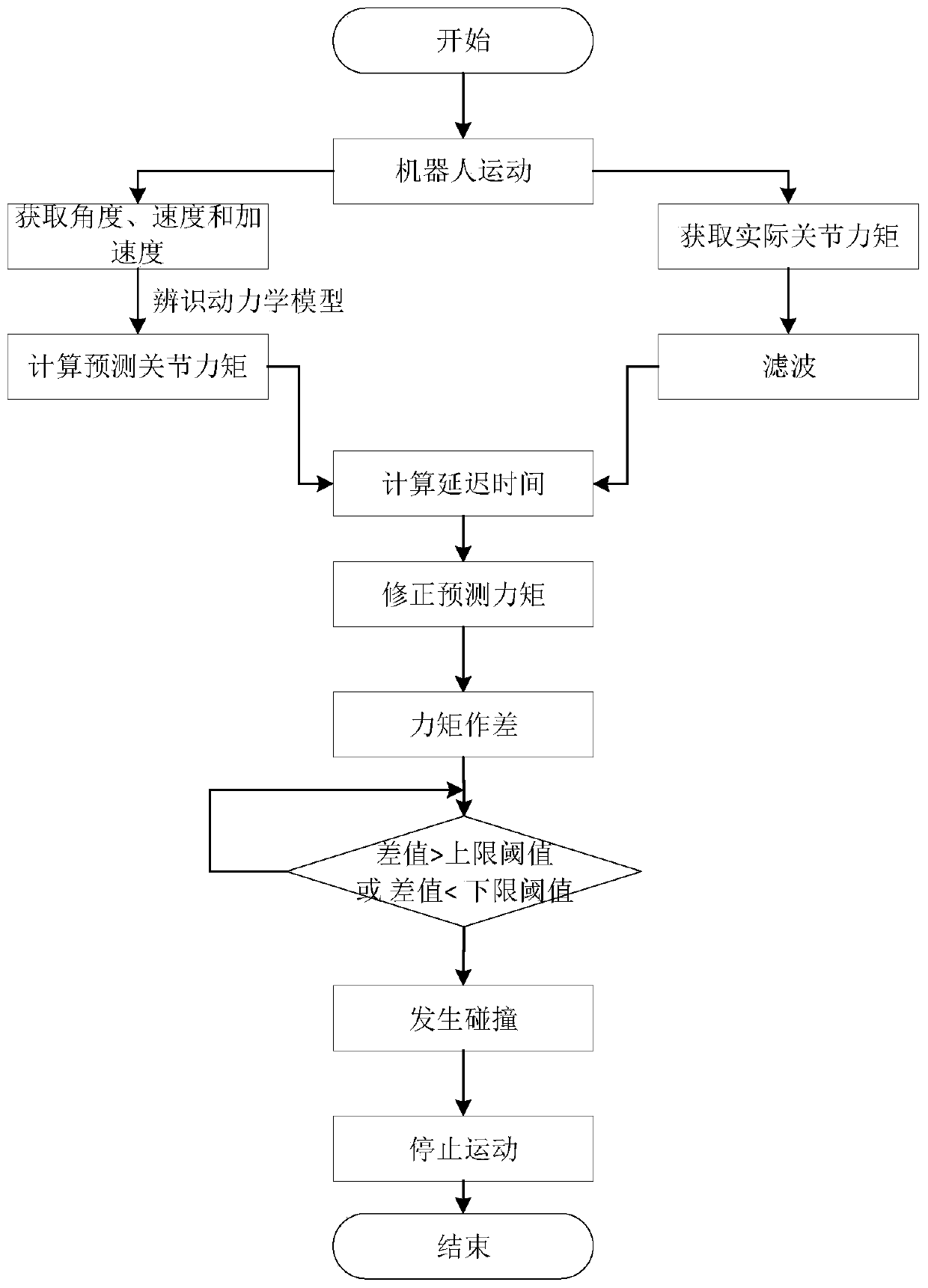

[0033] figure 1 It is a principle diagram of the industrial robot collision detection method of the present invention. The present invention takes the first joint of the industrial machine as the experimental object, and applies the collision detection algorithm of the present invention. Include the following steps:

[0034] Step 1: First obtain the actual joint torque M in real time through servo drive real .

[0035] Step 2: Filter the actual joint torque collected in step 1 to remove the influence of noise, and obtain the actual denoised joint torque filt(M real ).

[0036] Step 3: Use the robot dynamics model to calculate the joint torque and obtain the predicted joint torque M.

[0037] Step 4: Calculate the delay time t of the predicted torque relative to the actual denoised joint torque d , and correct the predicted moment.

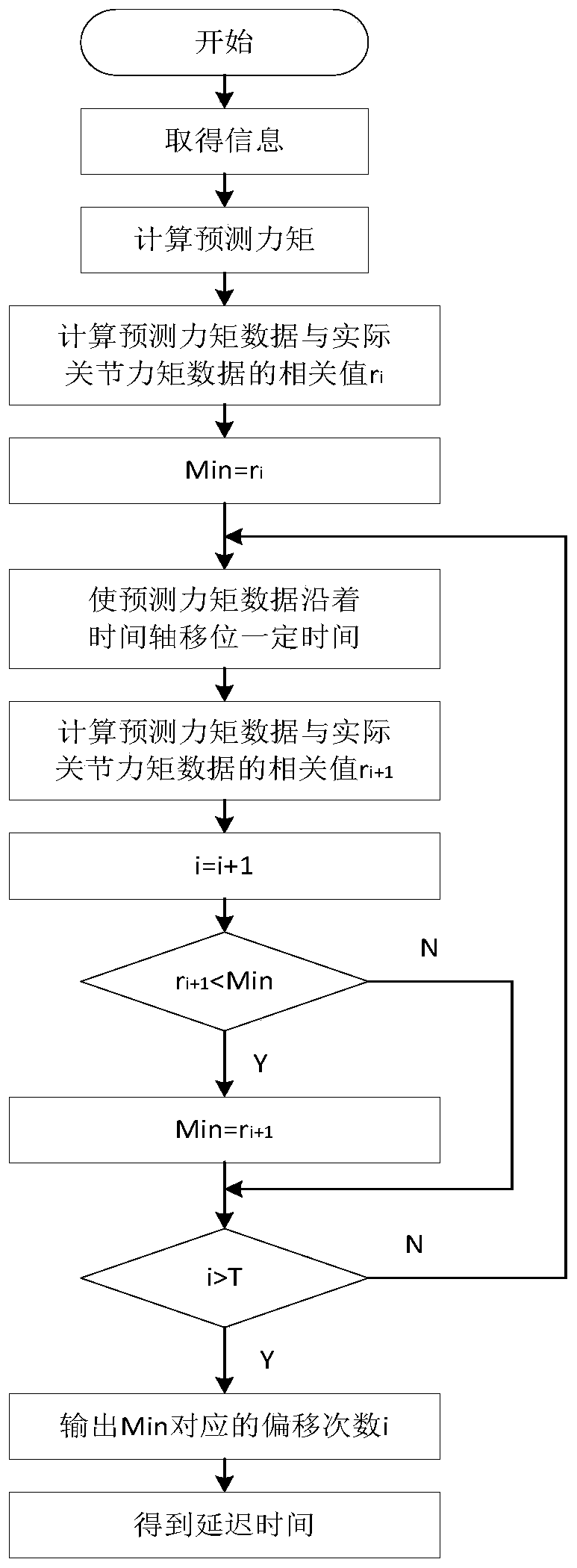

[0038] figure 2 is the specific step diagram for calculating the predicted torque delay time, and calculates the predicted torque delay ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com