Laser diode power supply structure

A technology of laser diodes and power supplies, which is applied in lasers, laser components, semiconductor lasers, etc., can solve the problems of expensive driver ICs, high costs, and low efficiency, and achieve the effects of easy procurement, low cost, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The features of the present invention and other relevant features are described in further detail below through the embodiments, so as to facilitate the understanding of those skilled in the art:

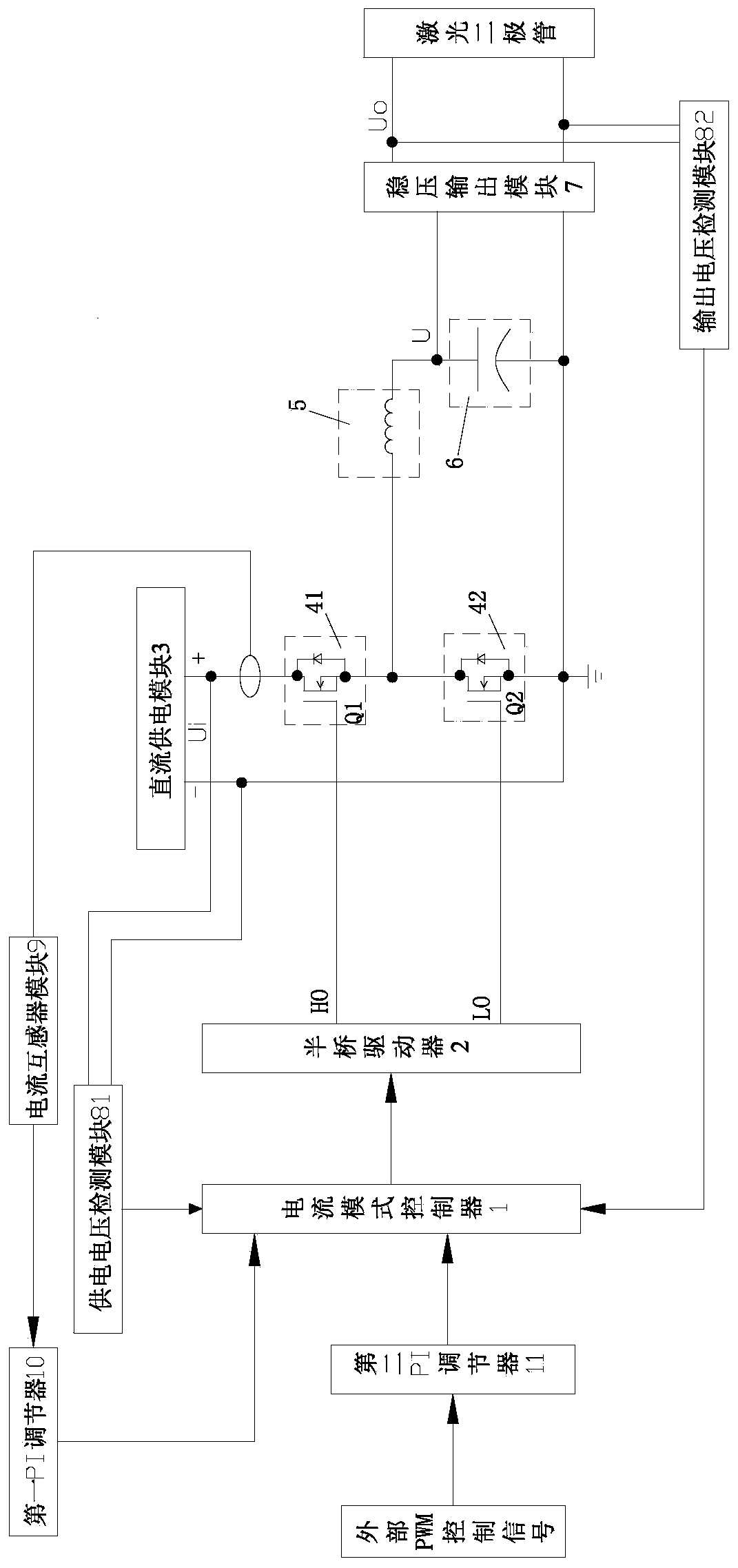

[0015] like figure 1 and figure 2 As shown, a laser diode power supply structure includes a current mode controller 1, a half-bridge driver 2 controlled by the current mode controller 1, and a positive voltage output terminal and a negative voltage connected to a DC power supply module 3 in sequence. The controlled high-side MOS transistor switch module 41 and the controlled low-side MOS transistor switch module 42 between the output connection terminals and driven by the half-bridge driver 2, the positive pole voltage of the controlled low-side MOS transistor switch module 42 is connected to An energy storage inductance 5 and a polar capacitor 6 are sequentially connected between the terminal and the negative voltage connection terminal, and a voltage stabilizing output mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com