Low-shrinkage ultra-high-strength concrete-reinforced concrete combined structure and construction method thereof

A technology of ultra-high-strength concrete and reinforced concrete, which is applied in building components, building structures, building insulation materials, etc., can solve the problems of steel corrosion, accelerated corrosion, reduction of concrete bond strength, etc., and achieve excellent chlorine resistance. Ion permeability, simple structure, effect of retarding corrosion damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

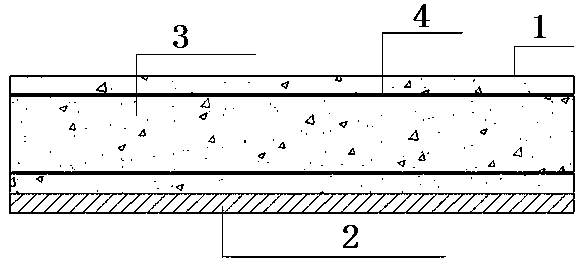

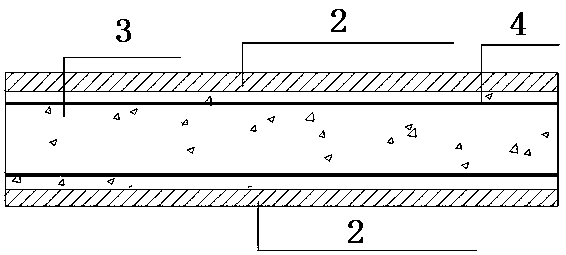

[0015] Such as Figure 1~2 As shown, a low-shrinkage ultra-high-strength concrete-reinforced concrete composite structure includes a reinforced concrete layer 1, and a low-shrinkage ultra-high-strength concrete protective layer 2 is poured on one or both sides of the reinforced concrete layer. Compared with ordinary concrete, ultra-high-strength concrete has excellent resistance to chloride ion penetration, and its chloride ion permeability coefficient is two orders of magnitude lower than ordinary concrete. Using ultra-high-strength concrete as the protective layer of reinforced concrete can significantly improve the chloride ion penetration resistance of reinforced concrete and greatly slow down the corrosion damage of steel bars.

[0016] In the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com