Method for forming nitride films through atomic layer deposition method

A technology of atomic layer deposition and nitride film, which is applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problems of film thickness difference in nitride furnace and inconsistency of nitride film thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] With the development of the manufacturing process of semiconductor devices, atomic layer deposition (Atomic layer deposition, ALD) has been widely used in the formation process of the gate sidewall layer.

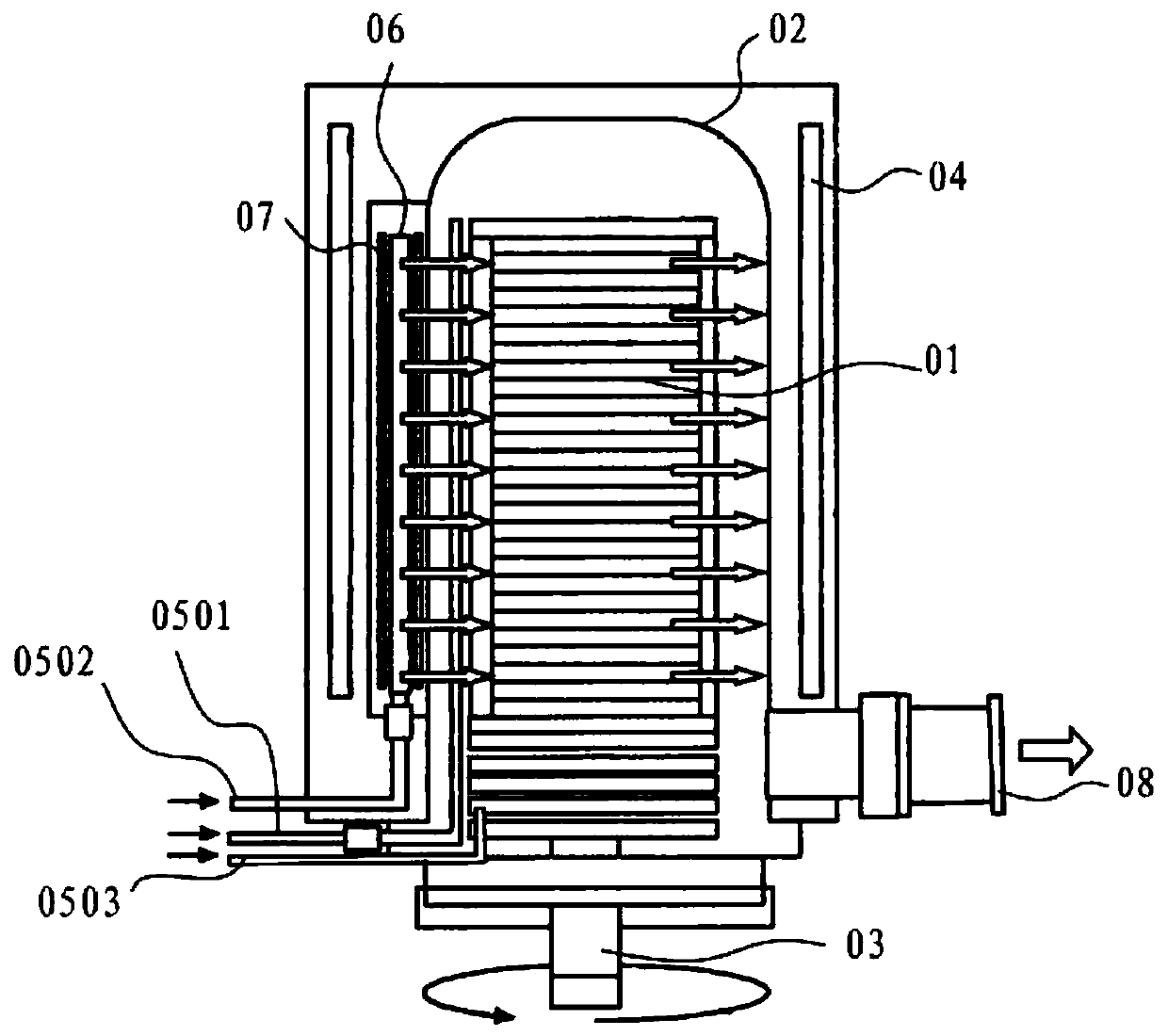

[0029] Atomic layer deposition (ALD) is a method that can coat a substance layer by layer on the surface of a substrate (wafer) in the form of a monoatomic film. The formation of a silicon nitride film uses the ALD method, and ALD SiN is Deposited at low temperature using a furnace tube. The structure of the furnace tube is as figure 1 shown. The furnace tube is a batch type vertical furnace, which can make a plurality of substrates (also called wafers or wafers) be supported in the respective boats 01 in a multi-stage manner at predetermined intervals, and the boats 01 are quartz boats , the boats 01 are contained in the cylindrical reaction chamber 02. During deposition, the boat 01 can be rotated by the rotation mechanism 03 . The heating mechanism 04 is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com