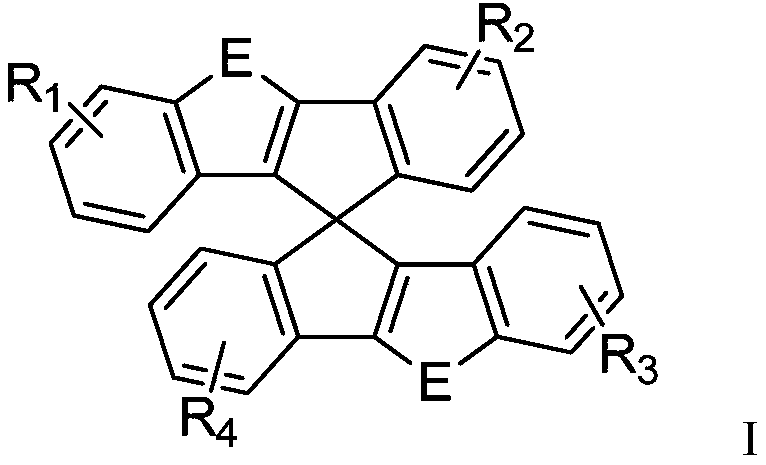

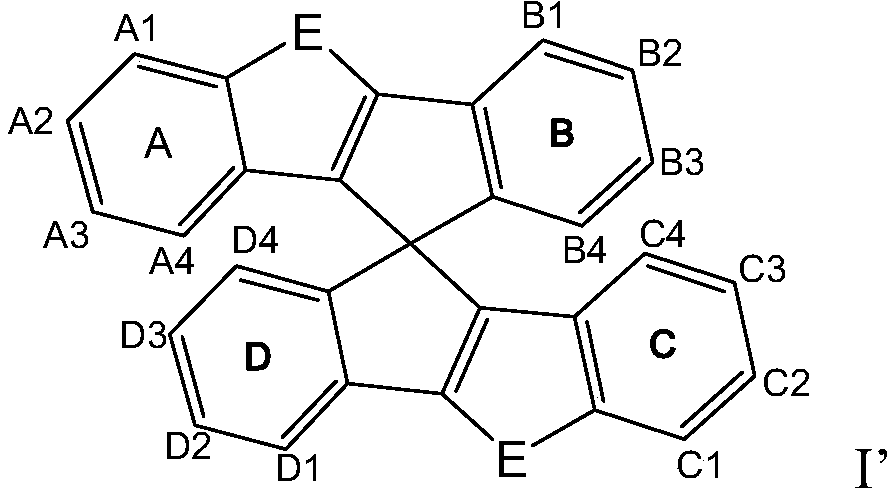

Novel compound with spiral structure and application of same to OLED device

A technology of spiro ring structure and compound, applied in the field of organic electroluminescence display, can solve the problems of film uniformity destruction, low glass transition temperature, easy crystallization of materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

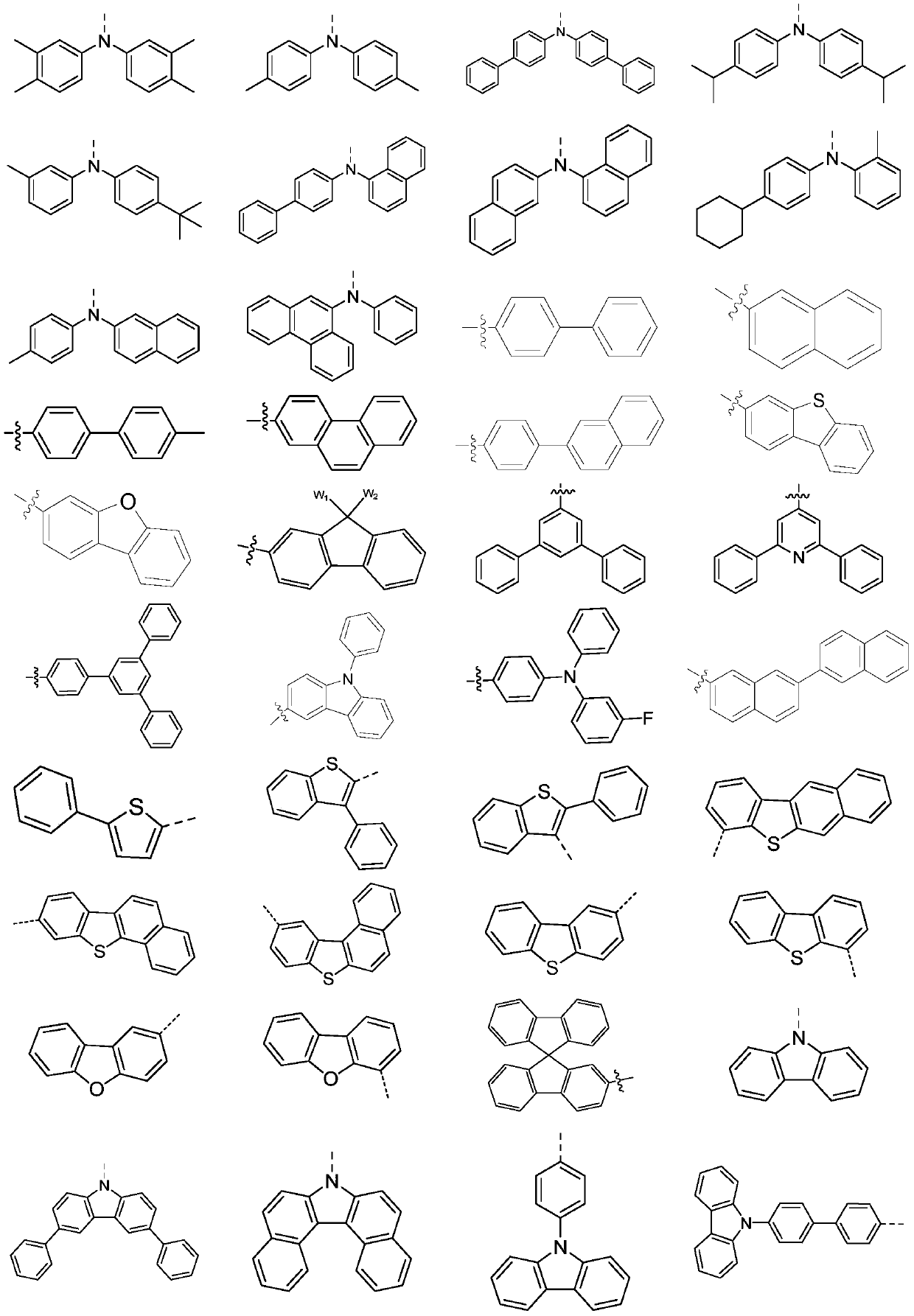

Method used

Image

Examples

Embodiment 1

[0060] Synthesis of (Compound 1-1)

[0061] The synthetic route is as follows:

[0062]

[0063] Including the following specific steps:

[0064] Synthesis of compound I-1

[0065] A 1-liter three-necked flask equipped with a magnetic stirrer, and potassium tert-butoxide (36.2 g, 0.376 mol), bis(4-tolyl)amine (41.37 g, 0.21 mol, purity 99%) and 100 ml of toluene were added sequentially after argon replacement. After replacing with argon again, 3.4 ml of tri-tert-butylphosphine and 0.5 g of palladium acetate were successively added. After the addition was complete, the temperature was raised to 85°C. Start to drop a solution consisting of (58.6g, 0.1mol, purity 99%) M1 and 100ml toluene, and control the temperature at 80-120°C. Cool down to 50°C, add 100ml of deionized water for hydrolysis, stir for 10 minutes, filter, and boil the filter cake several times with DMF, and rotary steam to obtain 68.80g of white solid with a purity of 99.5% and a yield of about 84%.

[0...

Embodiment 2

[0068] Synthesis of (Compound 1-30)

[0069] The synthetic route is as follows:

[0070]

[0071] Synthesis of compound I-30

[0072] 1 liter three-neck flask, equipped with magnetic stirring, after argon replacement, add potassium tert-butoxide (36.2g, 0.376mol), 4-tolyl-2-naphthylamine (48.93g, 0.21mol, purity 99%) and toluene 100ml . After replacing with argon again, 3.4 ml of tri-tert-butylphosphine and 0.5 g of palladium acetate were successively added. After the addition was complete, the temperature was raised to 85°C. Start to drop a solution consisting of (58.6g, 0.1mol, purity 99%) M2 and 100ml toluene, and control the temperature at 80-120°C. Cool down to 50°C, add 100ml of deionized water for hydrolysis, stir for 10 minutes, filter, boil the filter cake several times with DMF, and rotary evaporate to obtain 76.63g of white solid with a purity of 99.5% and a yield of about 86%.

[0073] Product MS (m / e): 890.28; Elemental analysis (C 63 h 42 N 2 S 2 ):...

Embodiment 3

[0075] Synthesis of (Compound I-76)

[0076] The synthetic route is as follows:

[0077]

[0078] Synthesis of compound I-76

[0079] A 1-liter three-neck flask equipped with a magnetic stirrer. After argon replacement, 19.93g (0.188mol) of sodium carbonate, 9,9-dimethyl-2-boronic acid (23.8g, 0.1mol, purity 99%) and 100ml of toluene were added in sequence. After replacing with argon again, 0.23g of Pd132 was added in sequence. After the addition, the temperature was raised to 80°C. Start to drop a solution consisting of (47.5g, 0.1mol, purity 99%) M3 and 100ml toluene, and control the temperature at 75-80°C. Cool down to room temperature, add 100ml of deionized water for hydrolysis, stir for 10 minutes, filter, and boil the filter cake several times with DMF to obtain 49.98g of white solid with a purity of 99.5% and a yield of about 85%.

[0080] Product MS (m / e): 588.21; Elemental analysis (C 44 h 28 o 2 ): theoretical value C: 89.77%, H: 4.79%, O: 5.44%; measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com