New technology using iron oxide red produced from steel plant pickling solution to prepare high-performance iron oxide for soft magnetic materials

A technology of iron oxide red and soft magnetic materials, applied in the direction of iron oxide/iron hydroxide, iron oxide, magnetic materials, etc., can solve the problem of inability to use high-performance iron oxide, etc., and achieve the effect of high product purity and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

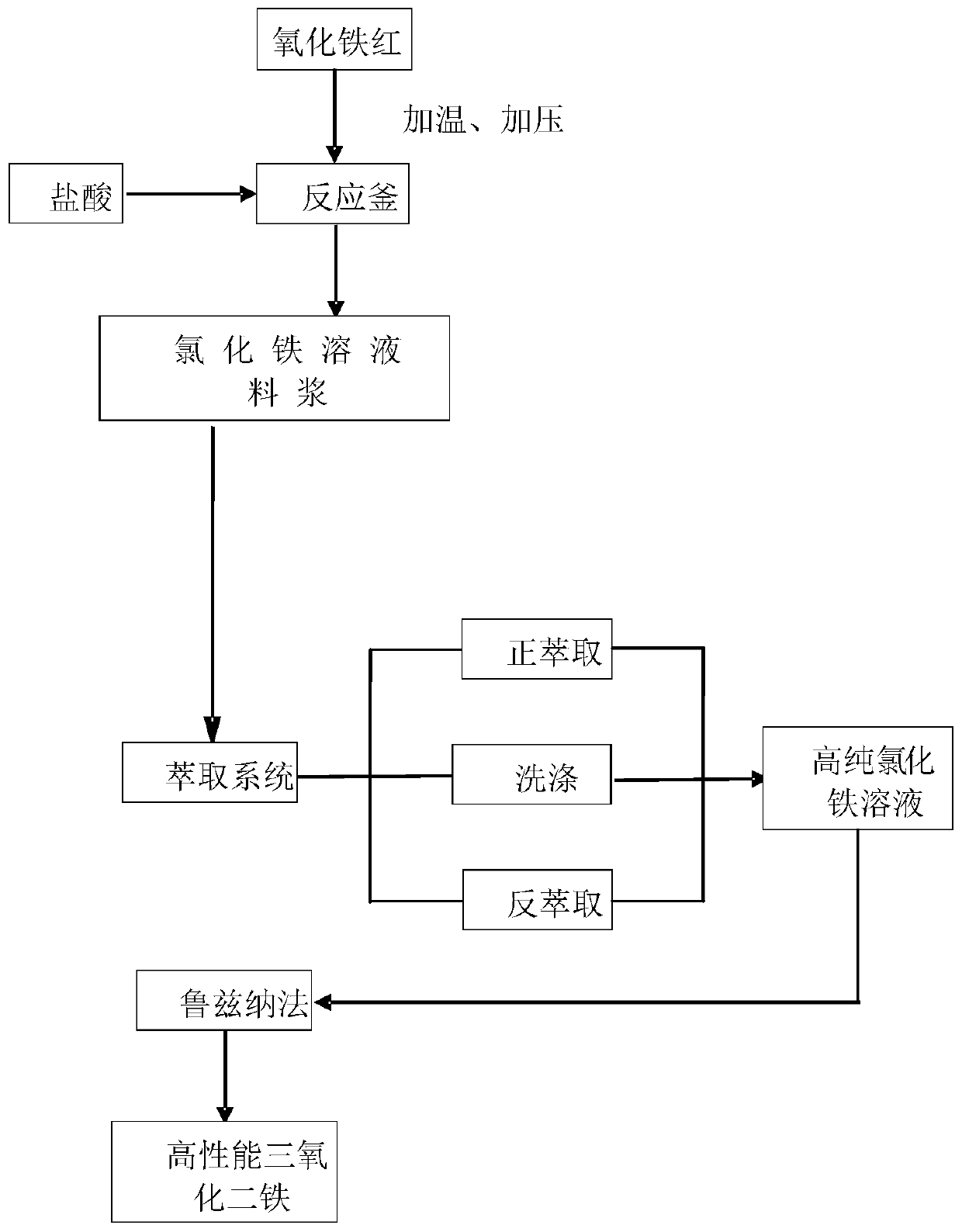

[0017] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the present invention will now be described with reference to the accompanying drawings.

[0018] like figure 1 As shown, the implementation case of the present invention proposes a new process for preparing high-performance iron oxide for soft magnetic materials from the iron oxide red produced by the pickling solution of the steel factory. New processes for using iron in soft magnetic materials include:

[0019] Step A: Prepare the red iron oxide powder produced by the steel mill pickling solution as a raw material;

[0020] Step B: first add hydrochloric acid into the reaction kettle, then add iron oxide red powder into the reaction kettle, then pressurize the reaction kettle to 1MPa, heat to 90°C, and react for 150 minutes to generate a solution containing ferric chloride;

[0021] Step C: Add hydrochloric acid to the ferric chloride solution to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com