Chip reaction device, manual sample introduction method and applications thereof

A reaction device and manual sampling technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., can solve the problems of difficulty in realization, poor fluid controllability, and high machining accuracy requirements, and achieve The effects of saving chip volume, simplifying chip structure, and flexible solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

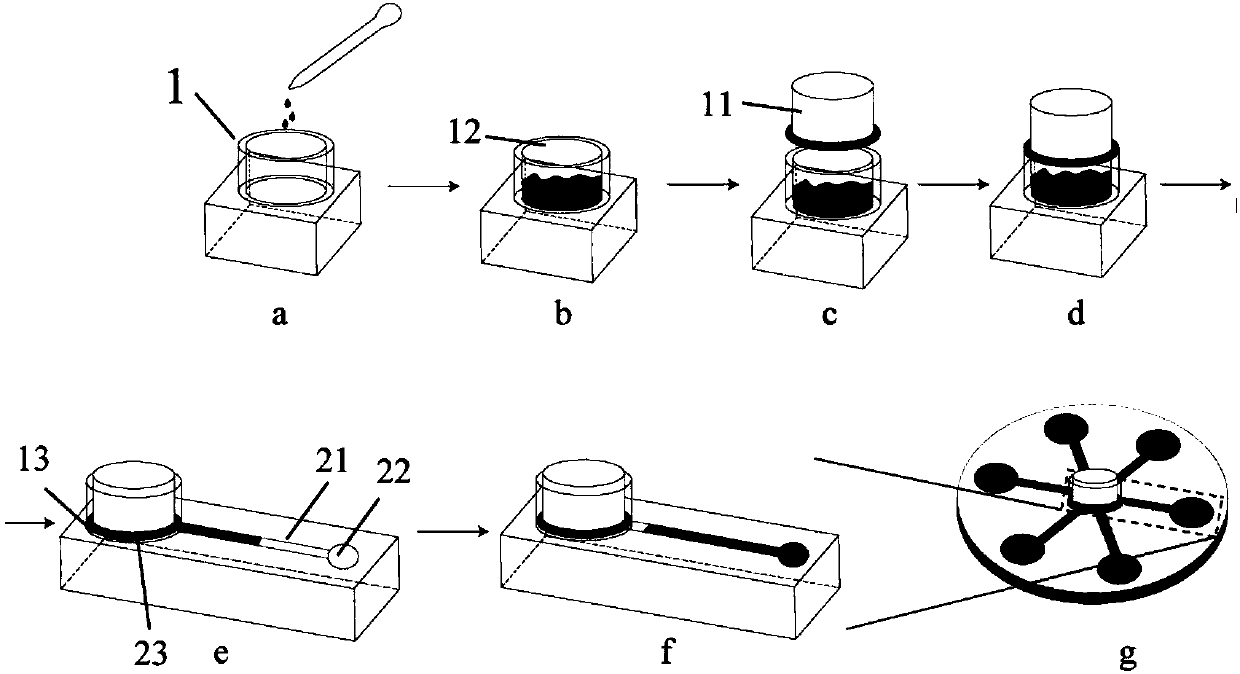

[0067] Such as figure 1 As shown, the chip reaction device includes a manual sampler 1 and a chip 2;

[0068] figure 1 Middle g shows the structure of the chip 2, the chip 2 is a circular scattering multi-channel chip, including 1 sample inlet 23 and 6 reaction pools 22 equidistant from the sample inlet 23, 6 flow channels Road 21 communicates with each reaction pool 22 and sample inlet 23 respectively; figure 1 In a-d, only the sample inlet 23 of the chip 2 is shown, and in e-f, only a group of flow channels 21 and the reaction pool 22 of the chip 2 are shown;

[0069]Described manual sample injector 1 comprises the cylindrical sample cuvette 12 of polyethylene system, cup-shaped control part 11 and sample discharge part 13, and described control part 11 is arranged on the inside of described sample cuvette 12, and described The sample pool 12 is detachably sealed and connected to allow the sample to enter and remain in the sample pool 12 or to push the sample out of the s...

Embodiment 2

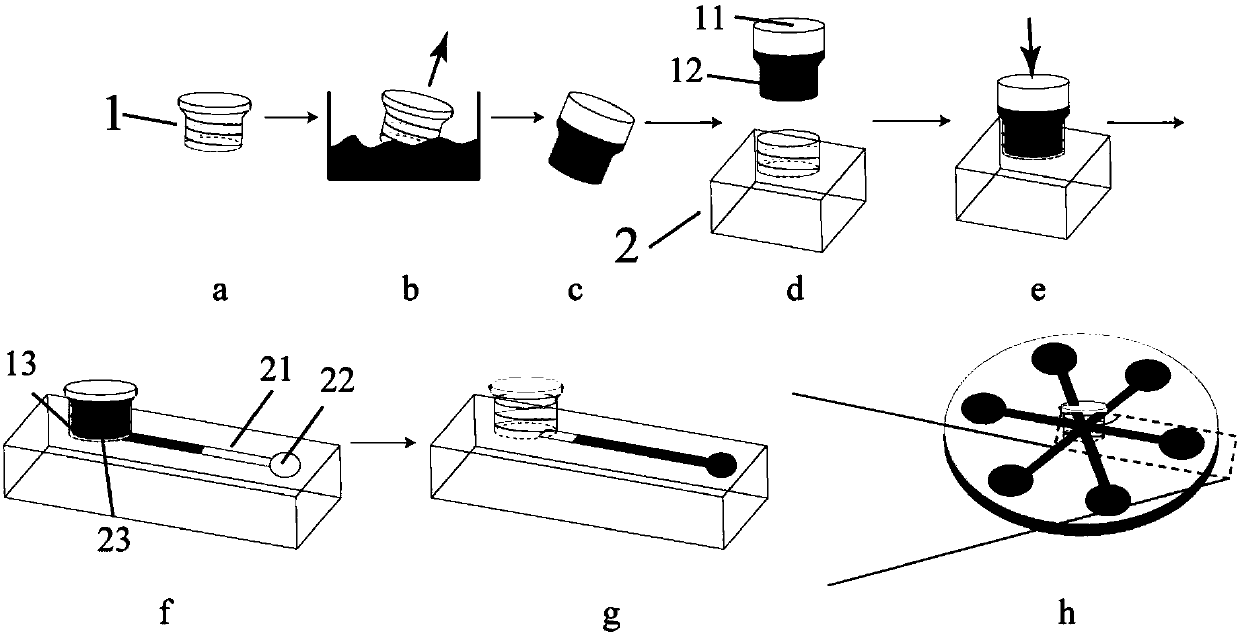

[0073] Such as figure 2 As shown, the chip reaction device includes a manual sampler 1 and a chip 2;

[0074] The structure of the chip 2 is the same as in Embodiment 1, figure 2 h shows the structure of chip 2, d-e shows only the sample inlet 23 of chip 2, f-g shows only a group of flow channels 21 and reaction pool 22 of chip 2, a-c shows manual sample injection The sample loading process of device 1;

[0075] Described manual sample injector 1 comprises the tubular sample cell 12 of polyethylene system, the cylindrical control part 11 that is connected with it and sample outlet 13, and described control part 11 is connected with the top of described sample cell 12, uses In order to make the sample enter and hold in the sample cell 12 or to push the sample out of the sample cell 12 through the sample outlet part 13, the control part includes a flexible side wall with variable height as its deformable part, the The deformation control of the stretchable side wall can cha...

Embodiment 3

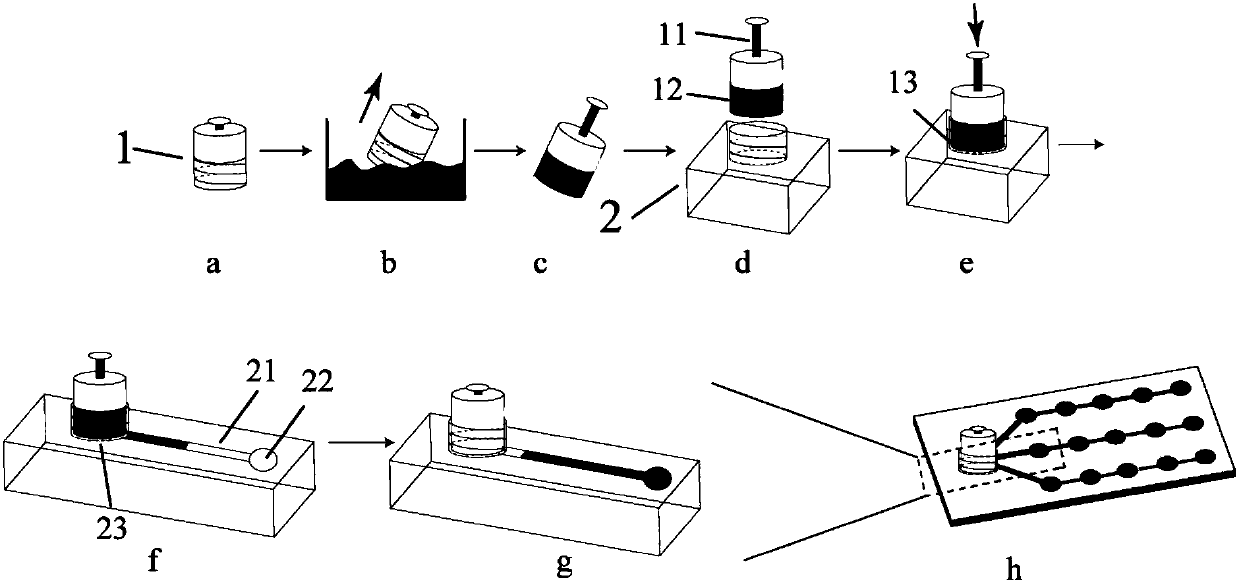

[0079] Such as image 3 As shown, the chip reaction device includes a manual sampler 1 and a chip 2;

[0080] image 3 Middle h shows the structure of the chip 2, the chip 2 is a parallel multi-channel rectangular chip, including three groups of five reaction pools 22 connected in series through the flow channels 21, and each group of reaction pools passes through the flow channels 21 and enters the The sample port 23 is connected; image 3 In d-e, only the sample inlet 23 of the chip 2 is shown, in f-g, only a set of flow channels 21 and the reaction pool 22 of the chip 2 are shown, and in a-c, the sample loading process of the manual injector 1 is shown;

[0081] The manual sample injector 1 comprises a cylindrical sample pool 12 made of polyethylene, a cylindrical control part 11 connected with a piston, and a sample outlet 13, and the control part 11 is connected with the sample pool 12 for making The sample enters and remains in the sample pool 12 or the sample is push...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com