Flue gas water capture apparatus based on ceramic membrane, and ceramic membrane cleaning process

A ceramic membrane and flue gas technology, applied in the field of flue gas water capture, can solve problems such as large water consumption, chemical cleaning agent consumption, and unclean cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] One embodiment of the present disclosure will be specifically described below, but the present disclosure is not limited thereto.

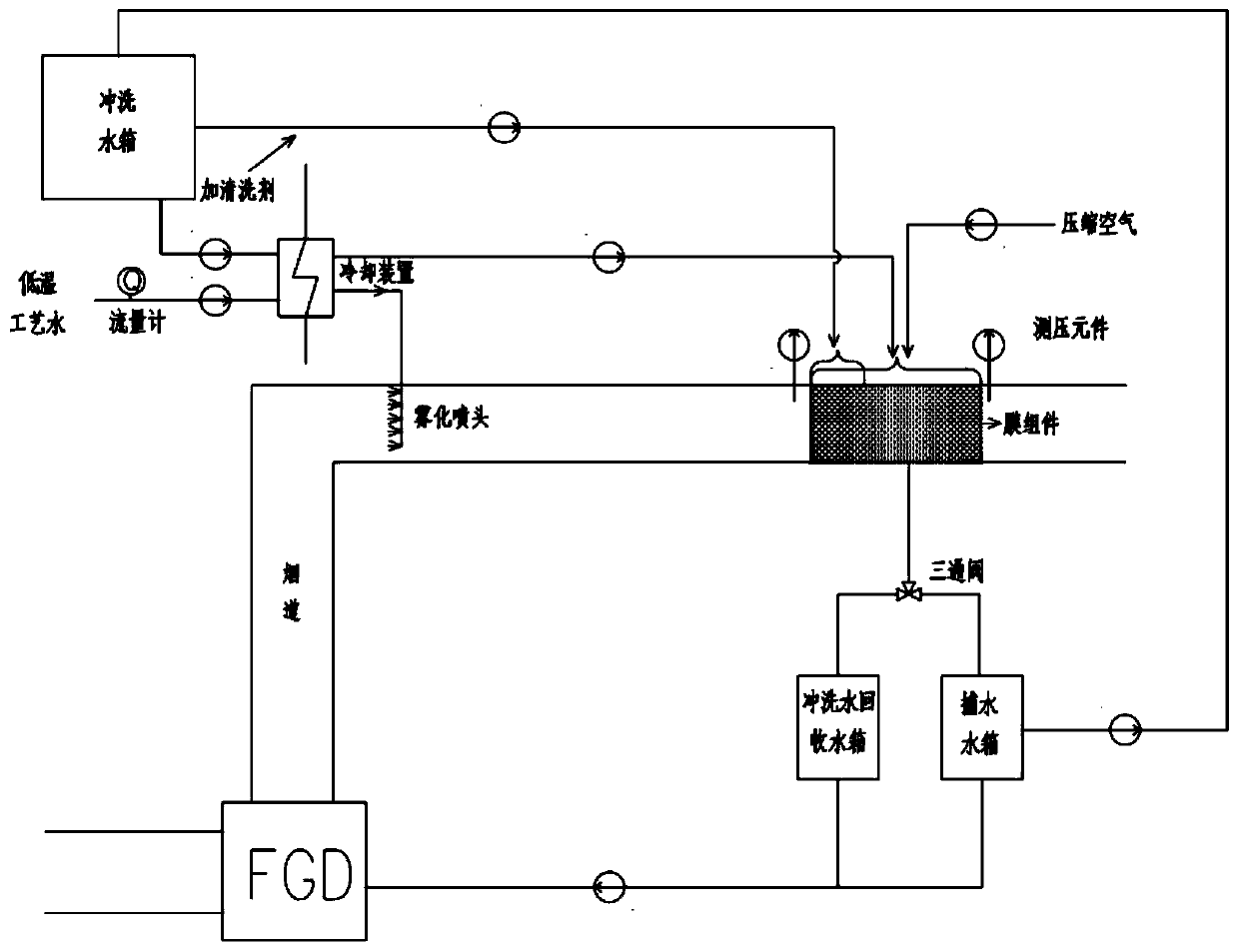

[0027] refer to figure 1 : After the flue gas passes through FGD, it forms steam-saturated flue gas. The water vapor is captured by the membrane module, and the captured water enters the water recovery tank. Directly used as process make-up water for FGD. The flushing device is composed of chemical cleaning and gas-liquid alternate backwashing. Chemical cleaning is used to clean the heavily polluted area in front of the ceramic membrane module by adding a special cleaning agent. Rinse thoroughly with rinse water. A low-temperature process spraying device is arranged in front of the ceramic membrane module, and the low-temperature process water and backwash water must pass through the low-temperature treatment device. The ceramic membrane module is equipped with pressure measuring elements before and after to control the start and stop of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com