Flavor essence and tobacco sheet for heat-not-burn cigarettes and non-burn cigarettes

A heat-not-burn and tobacco sheet technology, which is applied to tobacco, processed tobacco, essential oils/spices, etc., can solve the problems of not being able to obtain a clear fragrance and smoking feeling, weakening the fragrance and fragrance, and affecting the quality of cigarettes, achieving improvement and Effects of modifying aroma, improving inhalation and aftertaste, and increasing sensory comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

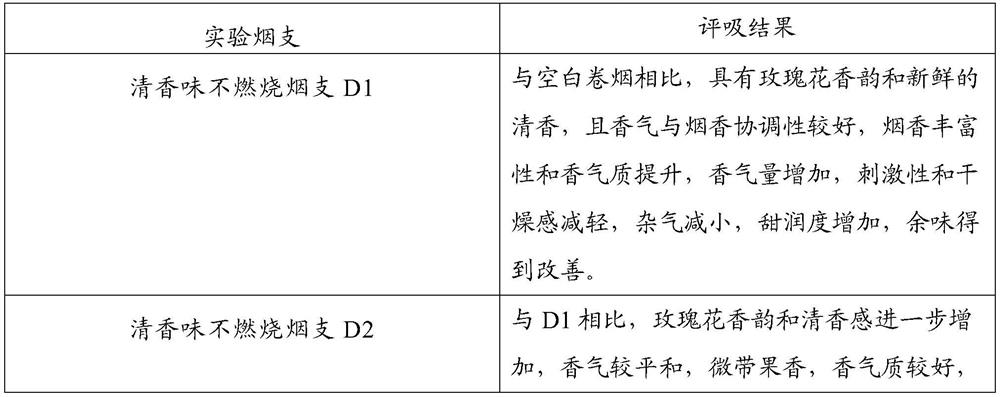

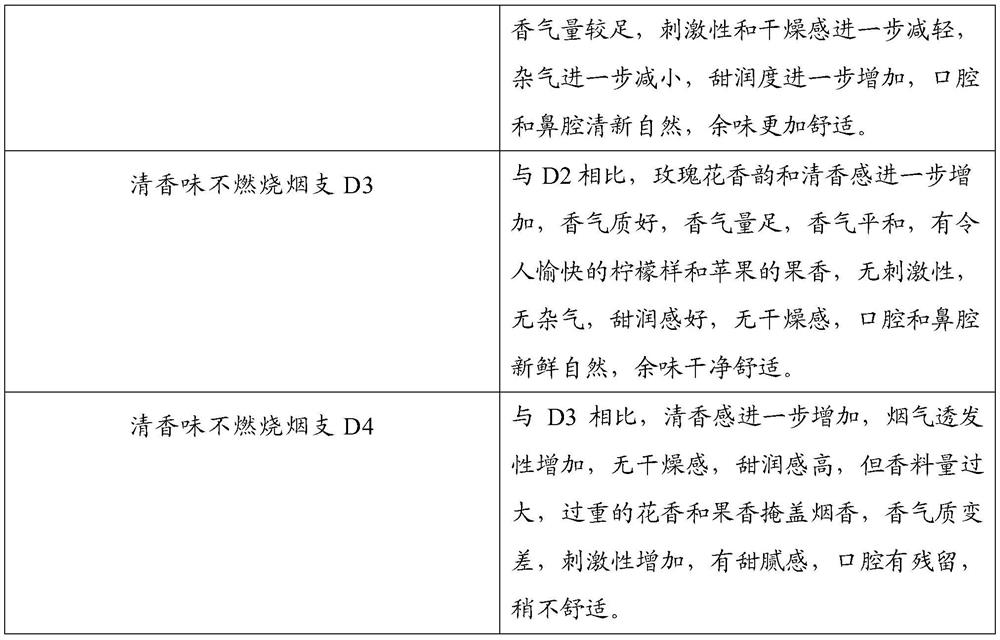

[0051] Benzyl alcohol -β-D- glucopyranoside 10g, phenylethyl alcohol -β-D- glucopyranoside 15g, leaf alcohol -β-D- glucopyranoside 5g, geraniol pyran -β-D- glucoside 5g, nerol -β-D- glucopyranoside and 3-oxo-4g -α- ionol -β-D- glucopyranoside 3g 916g of propylene glycol was added, stir, glycosides prepared fragrant group; lavender oil weighing 3g, cardamom oil 4g, rose oil 6g, cinnamon oil 1g, clary sage oil 2g, violet oil 3g, vanillin 4g, anisic aldehyde 3g, benzaldehyde and maple maple extract 1g 15g , mixed well by shaking and dissolved to prepare a fragrant auxiliary group; glycosides after incense fragrance yl group, and the auxiliary mixing prepared thoroughly shaken to obtain i.e. for heating without burning tobacco flavor fragrance S1.

[0052] After adding fragrance 6wt% tobacco flavor to the sheet S1, and then the scent of tobacco sheet made cigarette does not burn D1.

Embodiment 2

[0054] Benzyl alcohol -β-D- glucopyranoside 12g, phenylethyl alcohol -β-D- glucopyranoside 17g, leaf alcohol -β-D- glucopyranoside 6g, geraniol pyran -β-D- glucoside 6g, nerol -β-D- glucopyranoside and 3-oxo 5g -α- ionol -β-D- glucopyranoside 5g in 884g of propylene glycol, stir, glycosides prepared fragrant group; lavender oil Weigh 5g, cardamom oil 6g, rose oil 8g, cinnamon oil 3g, clary sage oil 5g, violet oil 5g, vanillin 6g, anisic aldehyde 5g, 2g and benzaldehyde maple maple extract 20g , mixed well by shaking and dissolved to prepare a fragrant auxiliary group; glycosides after incense fragrance yl group, and the auxiliary mixing prepared thoroughly shaken to obtain i.e. for heating without burning tobacco flavor fragrance S2.

[0055] After adding 7wt% of the perfume fragrance onto the tobacco sheet S2, and then the scent of tobacco sheet made cigarette does not burn D2.

Embodiment 3

[0057] Benzyl alcohol -β-D- glucopyranoside 14g, phenylethyl alcohol -β-D- glucopyranoside 18g, leaf alcohol -β-D- glucopyranoside 8g, geraniol pyran -β-D- glucoside 8g, nerol -β-D- glucopyranoside and 3-oxo 6g -α- ionol -β-D- glucopyranoside 6g in 864g of propylene glycol, stir, glycosides prepared fragrant group; lavender oil Weigh 5g, cardamom oil 8g, rose oil 8g, cinnamon oil 4g, clary sage oil 6g, violet oil 6g, vanillin 6g, anisic aldehyde 7g, 4g benzaldehyde and maple maple extract 22g , mixed well by shaking and dissolved to prepare a fragrant auxiliary group; glycosides after incense fragrance yl group, and the auxiliary mixing prepared thoroughly shaken to obtain i.e. for heating without burning tobacco flavor fragrance S3.

[0058] After adding fragrance 8wt% tobacco flavor to the sheet S3, and then the smell of tobacco sheet made cigarette does not burn D3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com