A Different Speed Double Electron Injection Gun

An electron injection and electron gun technology, which is applied to the discharge tube electron gun, the electron/ion gun of the transit time type electron tube, the transit time type electron tube, etc. , the effect of reducing the size and reducing the current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

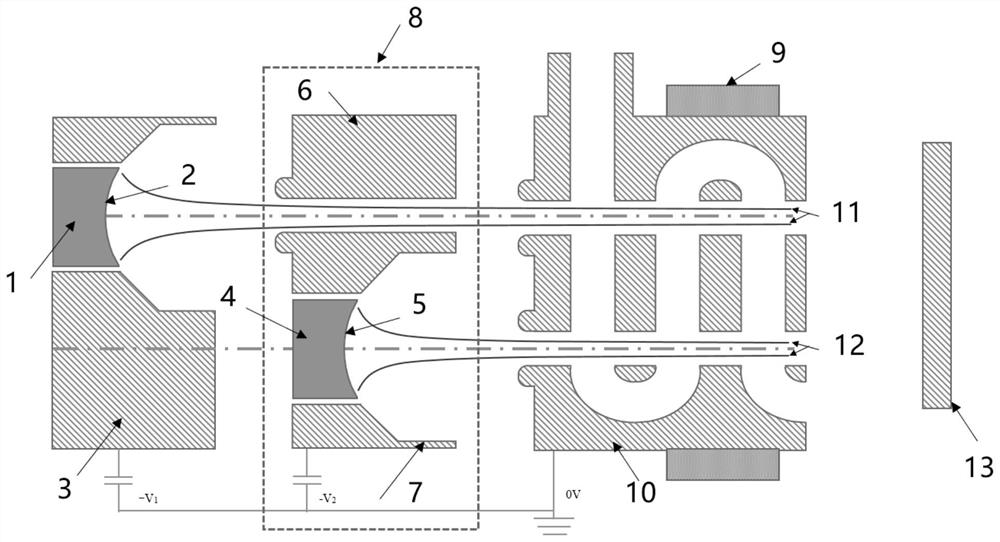

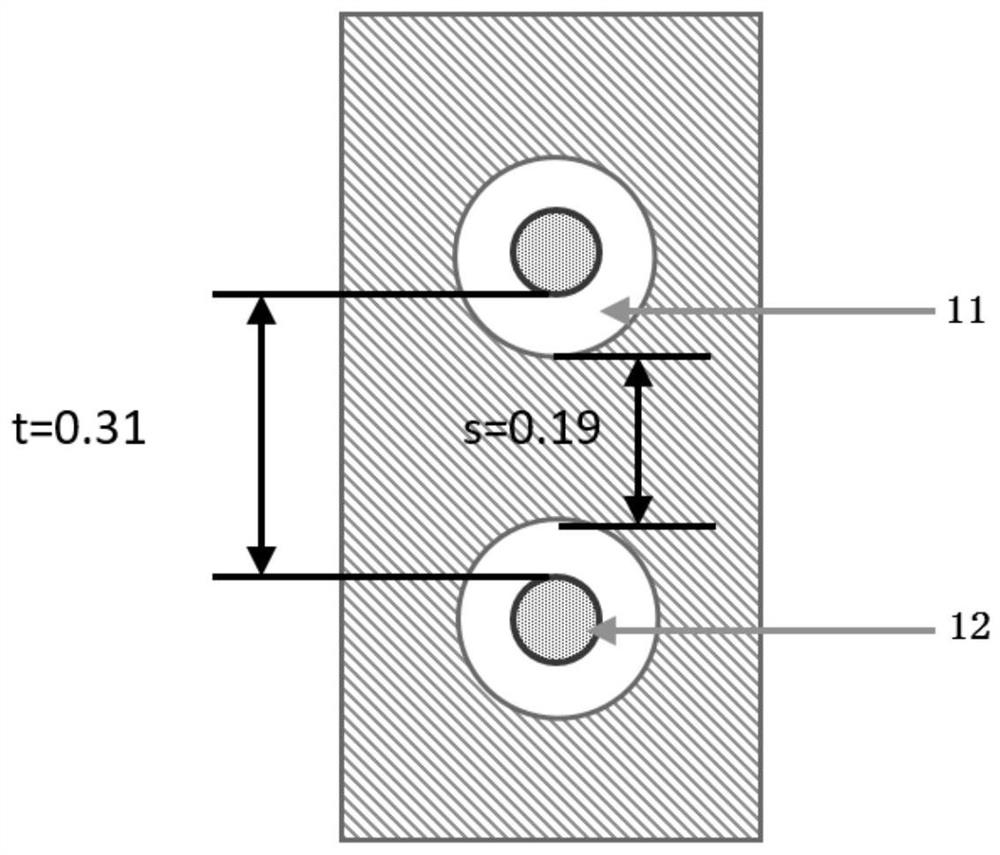

[0020] Such as figure 1 Shown is a different-speed electron injection gun of the present invention, including two electron injection channels, which are denoted as the first electron injection channel 11 and the second electron injection channel 12, and also sequentially include: a first cathode 1, a cathode-anode hybrid structure 8. The high-frequency system including the second anode 10 and the collector 13, the first electron beam emitted by the first cathode emitting surface 2 is transmitted along the first electron beam channel 11, and the first electron beam first passes through the first cathode 1 and the first electron beam. The voltage difference between the cathode and anode hybrid structure 8 is accelerated for the first time, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com