Electrode material, preparation method and application thereof

A technology of electrode materials and raw materials, which is applied in the fields of electrochemistry and electrode material preparation, can solve the problems of low power density, insufficient energy density, high power density, etc., and achieve the effects of improving conductivity, improving electrical storage performance, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

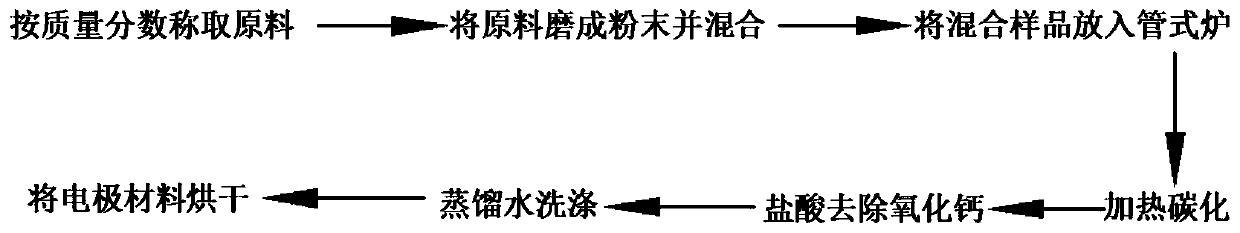

[0058] The present invention also provides a kind of preparation method of electrode material, comprises the following steps:

[0059] S1. Weighing raw materials according to the ratio of parts by mass;

[0060] S2. Grind the coal tar pitch, potassium hydroxide and nano-calcium oxide to a particle size of less than 180 mesh, and then mix them uniformly to obtain a mixed sample;

[0061] S3, transfer the mixed sample in S2 to the corundum boat, then put the corundum boat into the tube furnace, and feed inert gas;

[0062] S4, setting the heating program, heating and cooling naturally;

[0063] S5, taking the cooled corundum boat out of the tube furnace, and pickling the fired carbon material;

[0064] S6, separating the solid and liquid in the above mixed hydrochloric acid solution, and washing the solid with distilled water for 3-4 times until the pH of the solid is 6-7;

[0065] S7, drying to obtain the product.

[0066] As a preferred embodiment, the inert gas in step S3...

Embodiment 1

[0076] Such as figure 1 As shown, the electrode material preparation process of the present embodiment is as follows:

[0077] S1. Weigh raw materials according to parts by mass: 2 parts of coal tar pitch, 5 parts of nano calcium oxide, 10 parts of potassium hydroxide;

[0078] S2. Grind the coal tar pitch, potassium hydroxide and nano-calcium oxide to a particle size of less than 180 mesh, and then mix them uniformly to obtain a mixed sample;

[0079] S3, transfer the mixed sample in S2 to the corundum boat, then put the corundum boat into the tube furnace, and feed inert gas, the inert gas is preferably argon, and the flow rate of argon is 35ml / min;

[0080] S4. Set the heating program: the initial temperature is 20°C, and the heating rate is 4°C / min. When the temperature rises to 150°C, keep it warm for 30 minutes, then raise the temperature to 850°C at 4°C / min, keep it warm for 60 minutes, and finally cool down naturally ;

[0081] S5. Take out the cooled corundum boat ...

Embodiment 2

[0085] The difference between this embodiment and Example 1 is that the mass parts of raw materials are: 2 parts of coal tar pitch, 4 parts of nano-calcium oxide, and 10 parts of potassium hydroxide. The other step parameters and process conditions are the same as in Example 1. This implementation The prepared electrode material is denoted as HPC 2-4-10 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| mesopore | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com