Preparation method of ramie fibers for high-count textile fabric

A technology of textile fabrics and ramie fibers, applied in the field of textile fabrics, can solve problems such as difficulty in spinning high-count yarns, low counts of ramie fibers, and little added value, and achieve high degumming rate, soft and loose fibers, and less residual glue Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

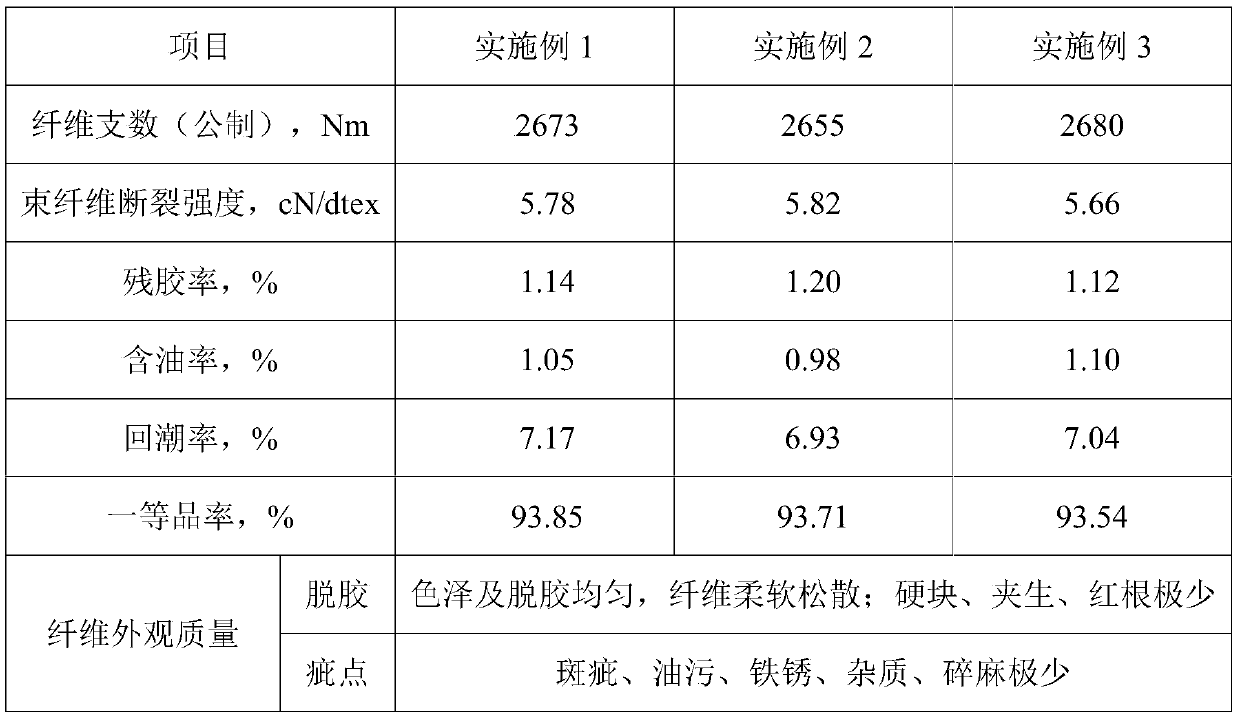

Examples

Embodiment 1

[0031] The preparation method of the high-count textile fabric of the present embodiment uses ramie fiber, comprises the steps:

[0032]1) Pre-soaking: according to the bath ratio of 1:3.0, immerse the raw ramie in the pre-soaking solution with a sodium hydroxide concentration of 20.0g / L for 20 minutes, then take it out and dry it for dehydration until the water content is 50%. , get prepreg;

[0033] 2) Steam explosion: put the prepreg obtained in step 1) into a steam explosion device for steam explosion, the steam temperature is 200°C, the explosion pressure is 3.2MPa, the heat preservation and pressure are maintained for 4.0min, and the pressure is released to obtain the steam explosion material;

[0034] 3) Scouring: according to the ratio of bath ratio of 1:10, the steam explosion material unloaded from the steam explosion device in step 2) is directly (interval time ≤ 2min) put into the scouring device filled with degumming liquid for scouring, 95°C heat preservation an...

Embodiment 2

[0039] The preparation method of the high-count textile fabric of the present embodiment uses ramie fiber, comprises the steps:

[0040] 1) Pre-soaking: according to the bath ratio of 1:3.5, immerse the raw ramie in the pre-soaking solution with a concentration of sodium hydroxide of 18.0g / L for 25 minutes, then take it out and dry it for dehydration until the water content is 50%. , get prepreg;

[0041] 2) Steam explosion: put the prepreg obtained in step 1) into a steam explosion device for steam explosion, the steam temperature is 210°C, the explosion pressure is 3.0MPa, the heat preservation and pressure are kept for 3.5min, and the pressure is released to obtain the steam explosion material;

[0042] 3) Scouring: According to the ratio of bath ratio of 1:11, the steam explosion material discharged from the steam explosion device in step 2) is directly (interval time ≤ 2min) put into the scouring device filled with degumming liquid for scouring, 95°C heat preservation an...

Embodiment 3

[0047] The preparation method of the high-count textile fabric of the present embodiment uses ramie fiber, comprises the steps:

[0048] 1) Pre-soaking: according to the bath ratio of 1:4.0, immerse the raw ramie in the pre-soaking solution with a sodium hydroxide concentration of 16.0g / L for 30 minutes, then take it out and dry it for dehydration until the water content is 50%. , get prepreg;

[0049] 2) Steam explosion: put the prepreg obtained in step 1) into a steam explosion device for steam explosion, the steam temperature is 205°C, the explosion pressure is 3.1MPa, the heat preservation and pressure are maintained for 4.5min, and the pressure is released to obtain the steam explosion material;

[0050] 3) Scouring: according to the ratio of bath ratio of 1:12, the steam explosion material discharged from the steam explosion device in step 2) is directly (interval time ≤ 2min) put into the scouring device filled with degumming liquid for scouring, 95°C heat preservation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com