Pressure-sensitive adhesive, pressure-sensitive adhesive tape, preparation method of the pressure-sensitive adhesive tape and medical dressing

A technology of pressure-sensitive adhesive and monomer, applied in the field of pressure-sensitive adhesive, to achieve the effects of high adhesive force, good water vapor transmission rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

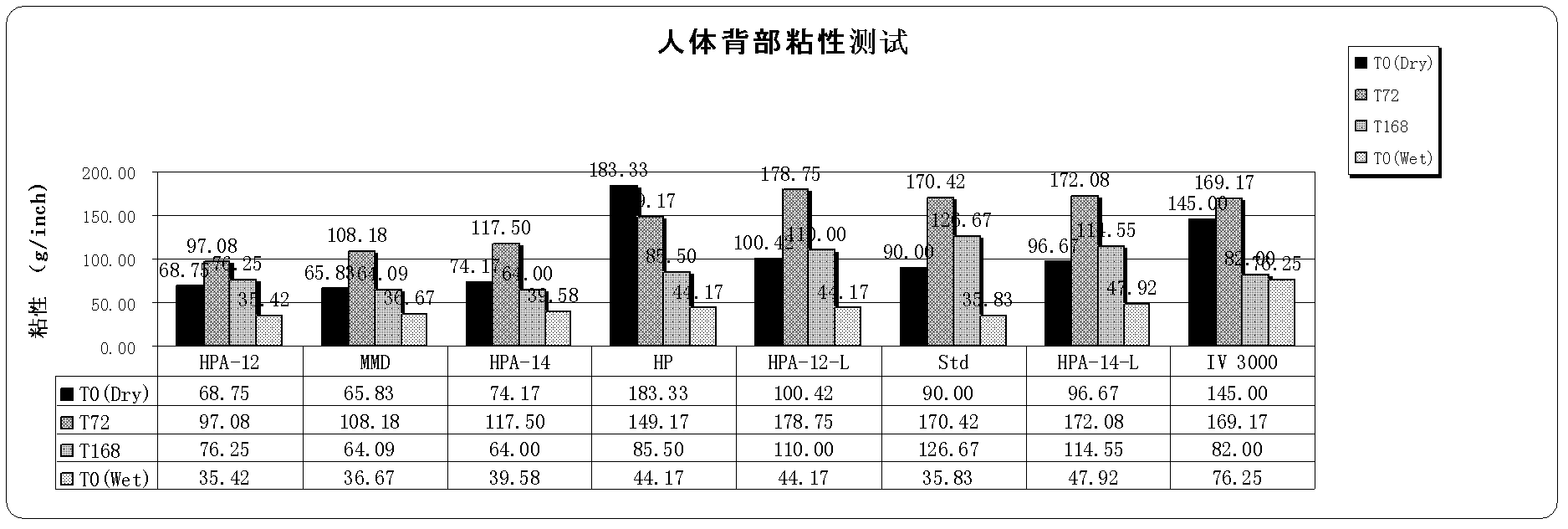

Examples

Embodiment Construction

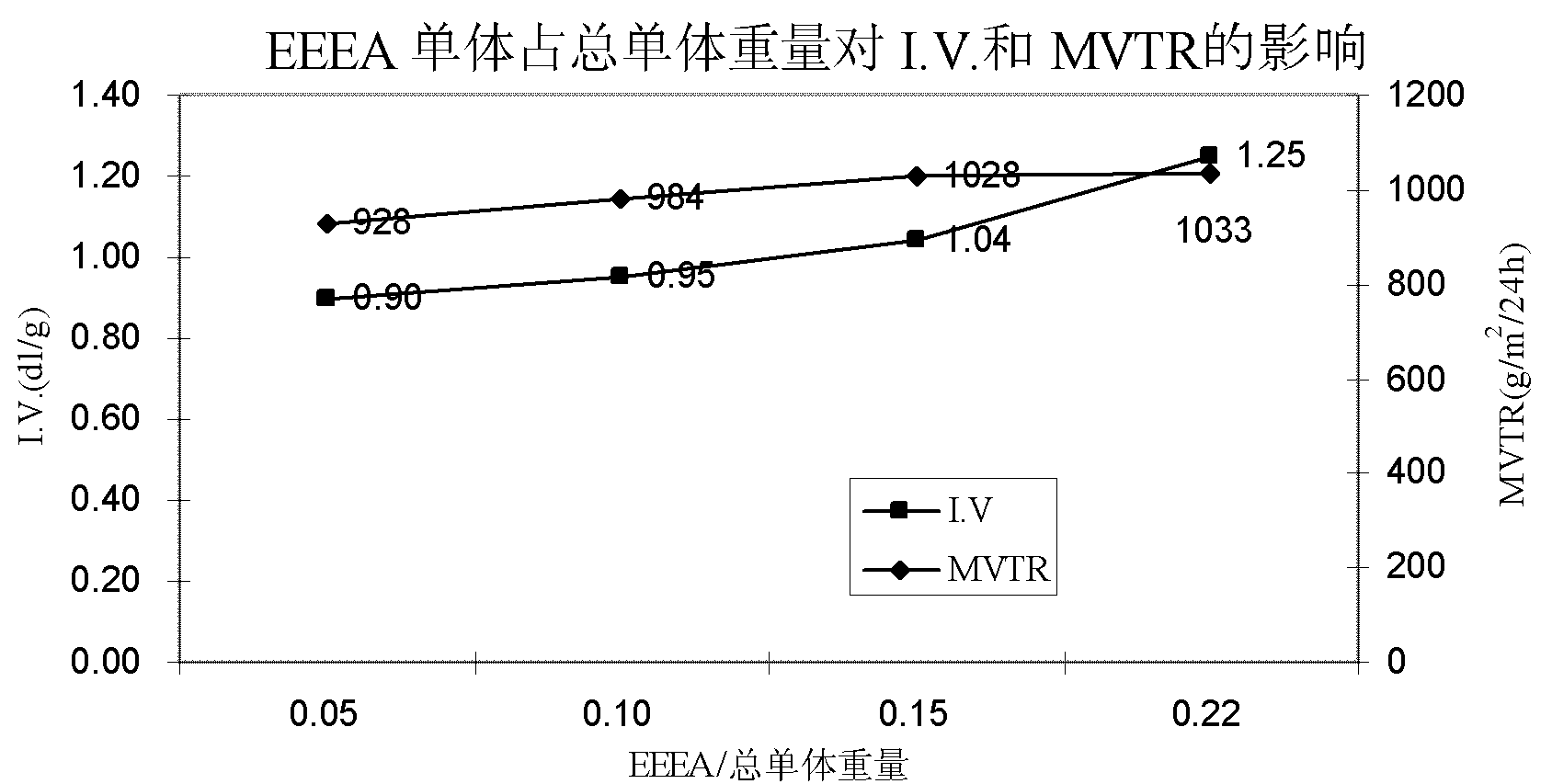

[0021] The acrylic pressure-sensitive adhesive of the present invention comprises a polymer formed by copolymerization of the following four monomers:

[0022] a). Hydrophilic acrylate monomers with hydroxyl or ethoxy groups;

[0023] b).Short-chain hydrophobic acrylate monomers, whose structural formula is CH 2 =CHCOOR 1 , R 1 is an alkyl group containing 1-5 carbon atoms;

[0024] c). Long-chain hydrophobic acrylate monomers whose structural formula is CH 2 =CHCOOR 2 , R 2 is an alkyl group containing 6-14 carbon atoms;

[0025] d). A propylene-based monomer having a polar group that can be copolymerized with the above-mentioned monomers a-c.

[0026] The copolymerization method may be a conventional radical polymerization method. In a specific embodiment, the specific conditions of the polymerization reaction are as follows:

[0027] Add all the monomers and solvents into a 1000-gallon reactor in sequence. The ratio of monomers and solvents is shown in Table 2. Sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com