Method for preparing high-performance composite material by depositing polymer micro-nano particles on surface of carbon fiber through electrophoresis

A technology of electrophoretic deposition and composite materials, applied in the direction of carbon fiber, electrophoretic plating, fiber processing, etc., can solve the problems of long reaction time, severe reaction conditions, and reduced tensile strength of CF monofilament.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

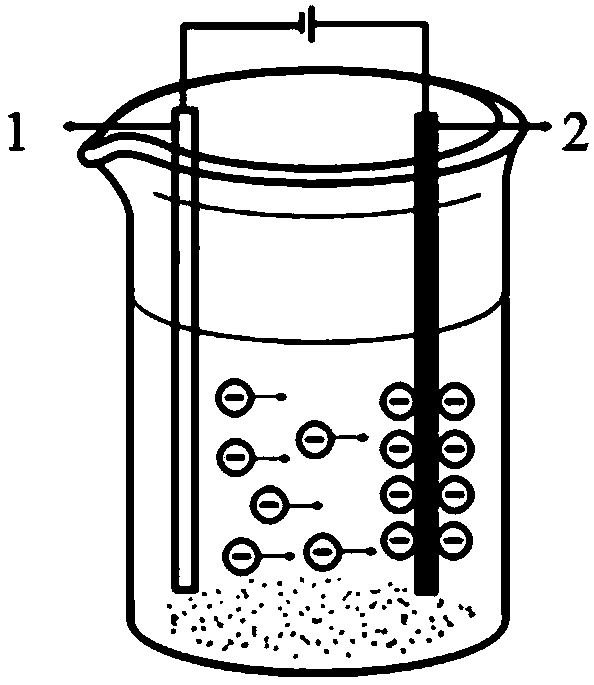

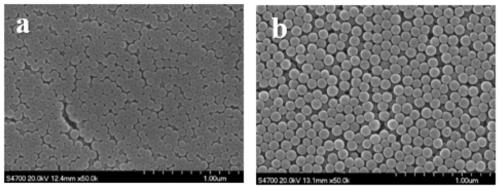

[0056] Disperse styrene (St) and acrylic acid (AA) copolymerized microspheres (Poly(St-co-AA, non-crosslinked), particle size 70nm, smooth surface, spherical shape, containing carboxyl group) in water to form a concentration of 0.032g / ml dispersion; figure 1 In the electrophoresis device shown, the aluminum plate is connected to the negative pole of the power supply, and the carbon fiber (CF) tow is connected to the positive pole of the power supply, and the polymer microsphere dispersion is added for electrophoretic deposition. The voltage is 5v, and the electrophoresis time is 120min. Dry in a vacuum oven at room temperature for use.

Embodiment 2

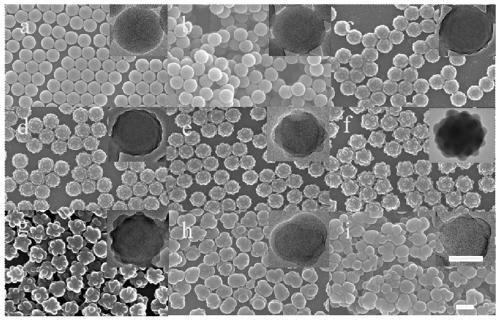

[0058] As in Example 1, only the polymer microspheres used are styrene (St) and methacrylic acid (AA) copolymerized microspheres (Poly(St-co-MAA), particle diameter 81nm, smooth surface, spherical, carboxyl-containing); The electrophoresis voltage was 10v, and the electrophoresis time was 30min.

Embodiment 3

[0060] As in Example 1, except that the polymer microspheres used are styrene (St) and N-succinimide methacrylate (NSMA) copolymerized microspheres (Poly(St-co-NSMA), particle diameter 98nm, surface slightly Rough, spherical, containing succinimide group); electrophoresis voltage is 15v, electrophoresis time is 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com