Production method for large-thickness Q500-grade steel plate

A production method and large-thickness technology, applied in the field of metallurgy, can solve problems such as high internal quality, unstable guarantee, low-cost price, etc., achieve high production efficiency, excellent internal quality, and ensure the quality of billets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

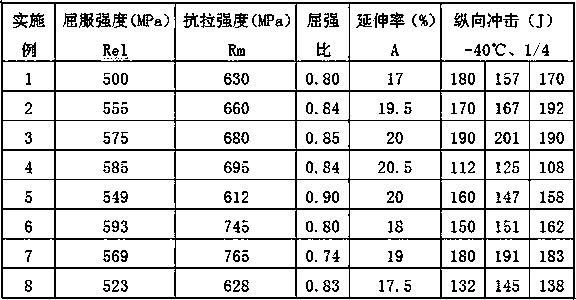

Examples

Embodiment 1

[0018] The thickness of Q500D steel plate in this example is 300mm, its chemical composition and mass percentage are: C: 0.16%, Mn: 1.7%, V: 1.53%, N: 125ppm, B: 0.0018%, and other components meet GB / T1591 requirements.

[0019] The production method of the large-thickness Q500 grade steel plate in this embodiment includes blank making, heating, rolling, and heat treatment processes, and the specific process steps are as follows:

[0020] (1) Billet making process: 2 billets of the same size and furnace number are used for composite billet making; after spot welding and centering process, the billets are put into a small heating furnace and preheated by electric heating in a vacuum chamber , the preheating temperature is 300°C, and the holding time is 30 minutes; when vacuum welding, use two vacuum electron beam welding guns for welding, one of which is used for small energy welding, and the welding line energy is 20KJ / cm 3 , another electron beam gun welding line energy 30KJ...

Embodiment 2

[0026] The thickness of Q500D steel plate in this example is 320mm, its chemical composition and mass percentage are: C: 0.18%, Mn: 1.85%, V: 1.72%, N: 183ppm, B: 0.0022%, and other components meet GB / T1591 requirements.

[0027] The production method of the large-thickness Q500 grade steel plate in this embodiment includes blank making, heating, rolling, and heat treatment processes, and the specific process steps are as follows:

[0028] (1) Billet making process: 2 billets of the same size and furnace number are used for composite billet making; after spot welding and centering process, the billets are put into a small heating furnace and preheated by electric heating in a vacuum chamber , the preheating temperature is 350°C, and the holding time is 35 minutes; when vacuum welding, two vacuum electron beam torches are used for welding, one of which is used for small energy welding, and the welding line energy is 22KJ / cm 3 , another electron beam gun welding line energy 37K...

Embodiment 3

[0034] The thickness of Q500C steel plate in this example is 340mm, its chemical composition and mass percentage are: C: 0.19%, Mn: 1.72%, V: 1.90%, N: 230ppm, B: 0.0027%, and other components meet GB / T1591 requirements.

[0035] The production method of the large-thickness Q500 grade steel plate in this embodiment includes blank making, heating, rolling, and heat treatment processes, and the specific process steps are as follows:

[0036] (1) Billet making process: 2 billets of the same size and furnace number are used for composite billet making; after spot welding and centering process, the billets are put into a small heating furnace and preheated by electric heating in a vacuum chamber , the preheating temperature is 380°C, and the holding time is 40 minutes; during vacuum welding, two vacuum electron beam torches are used for welding, one of which is used for small energy welding, and the welding line energy is 24KJ / cm 3 , another electron beam gun welding line energy 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com