Physicochemical sewage processing system and method for simultaneously removing COD and total phosphorus

A sewage treatment system, sewage technology, applied in water/sewage treatment, water/sludge/sewage treatment, magnetic field/electric field water/sewage treatment, etc., can solve problems such as pump blockage, improve adsorption capacity, improve COD removal rate, sludge settling effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

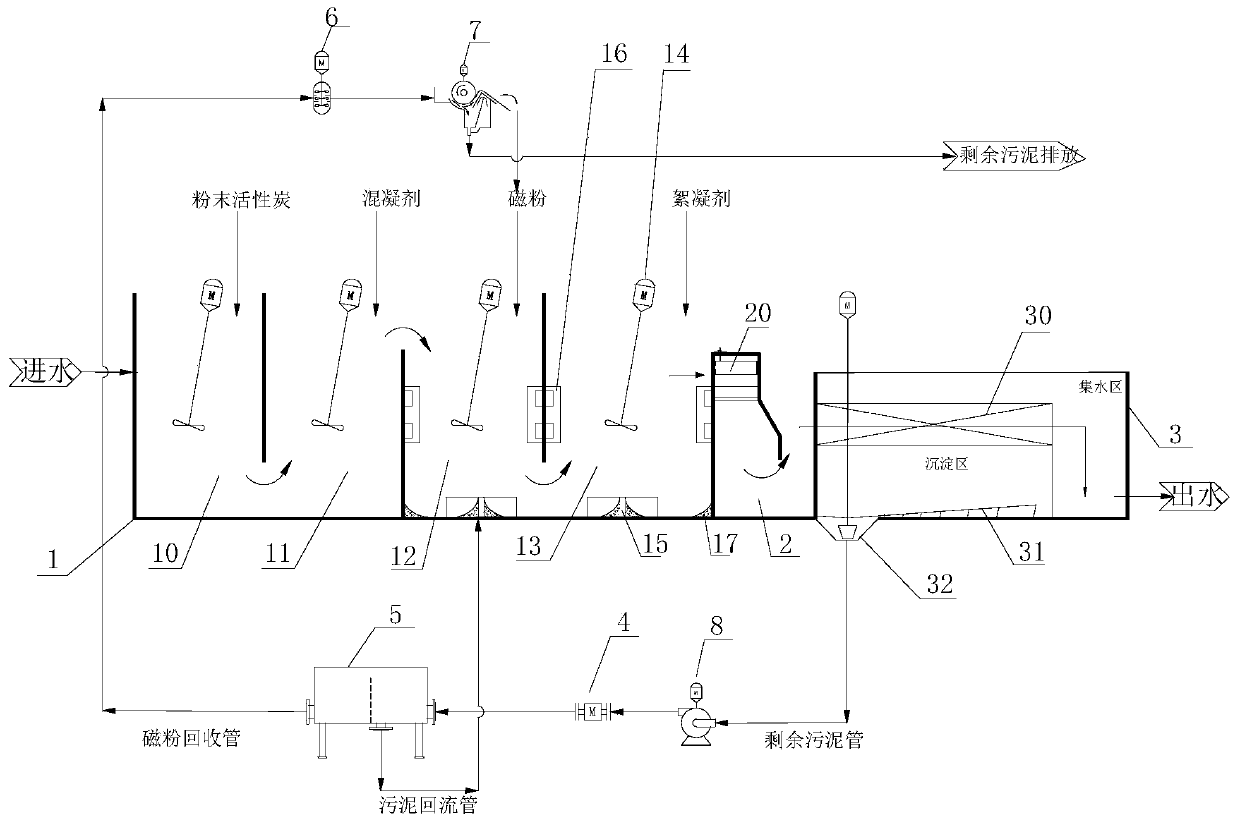

[0051] Such as figure 1 As shown, a physical and chemical sewage treatment system for synchronous removal of COD and total phosphorus, including an improved reaction tank 1, an improved advection sedimentation tank 3, a magnetic particle recovery system and a sludge discharge system.

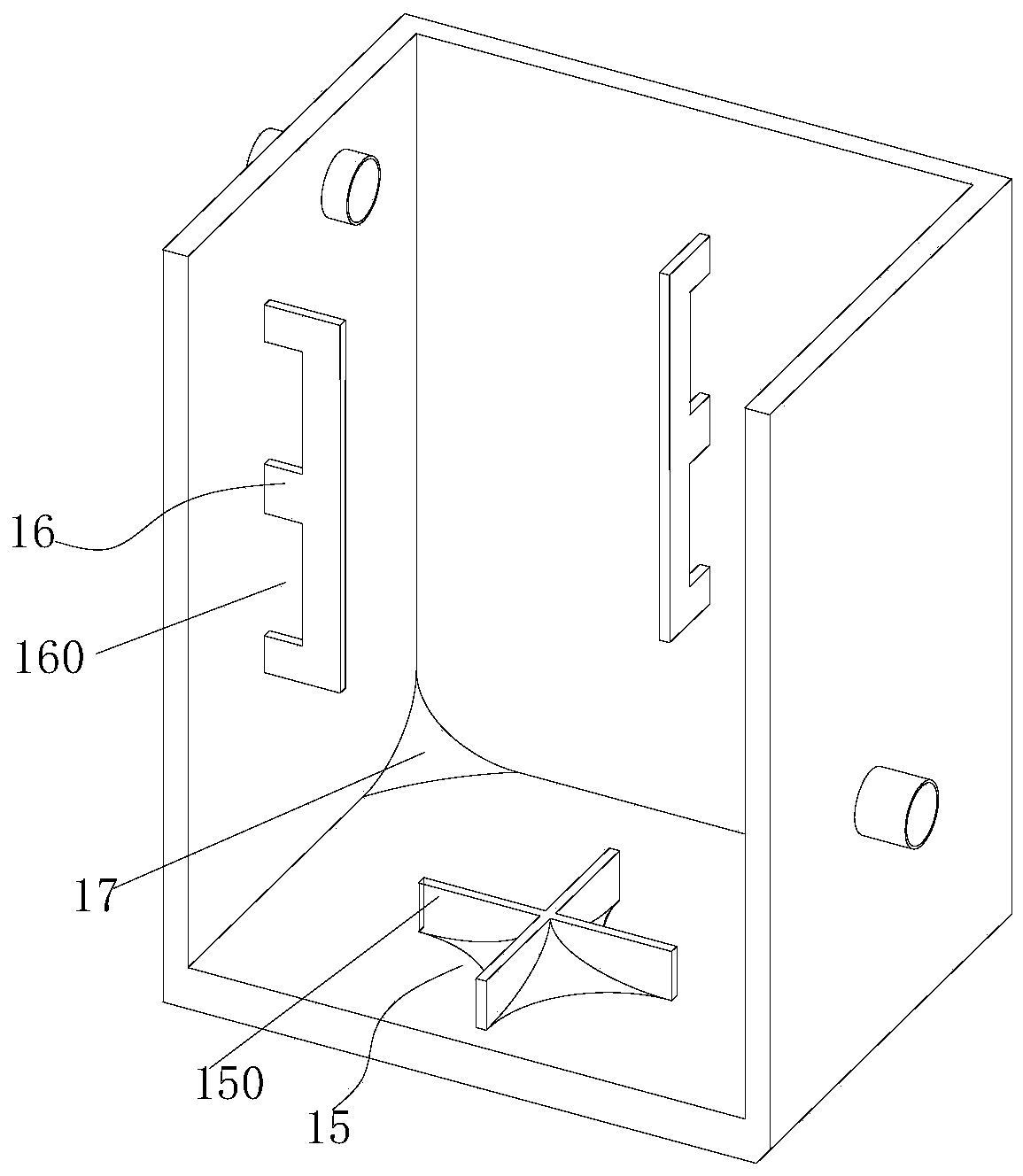

[0052] The interior of the improved reaction tank 1 is divided into a coagulation reaction zone 11, a magnetic powder loading zone 12, and a flocculation reaction zone 13 by partitions. The center of the bottom is provided with a first deflector 15, and the side walls are respectively provided with a second deflector 16, and the two sides of the partition in the middle of the magnetic powder loading area 12 and the flocculation reaction area 13 are also respectively provided with a second deflector. plate 16.

[0053] A water distribution regulation area 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com