Electron device packaging box carrying mechanical device and operation method thereof

A technology of electronic devices and handling machinery, applied in the directions of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of inconvenience for accurate packaging and accurate scanning of packaging machines, large randomness of placement positions, and high labor intensity. Inaccurate placement, compact structure, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

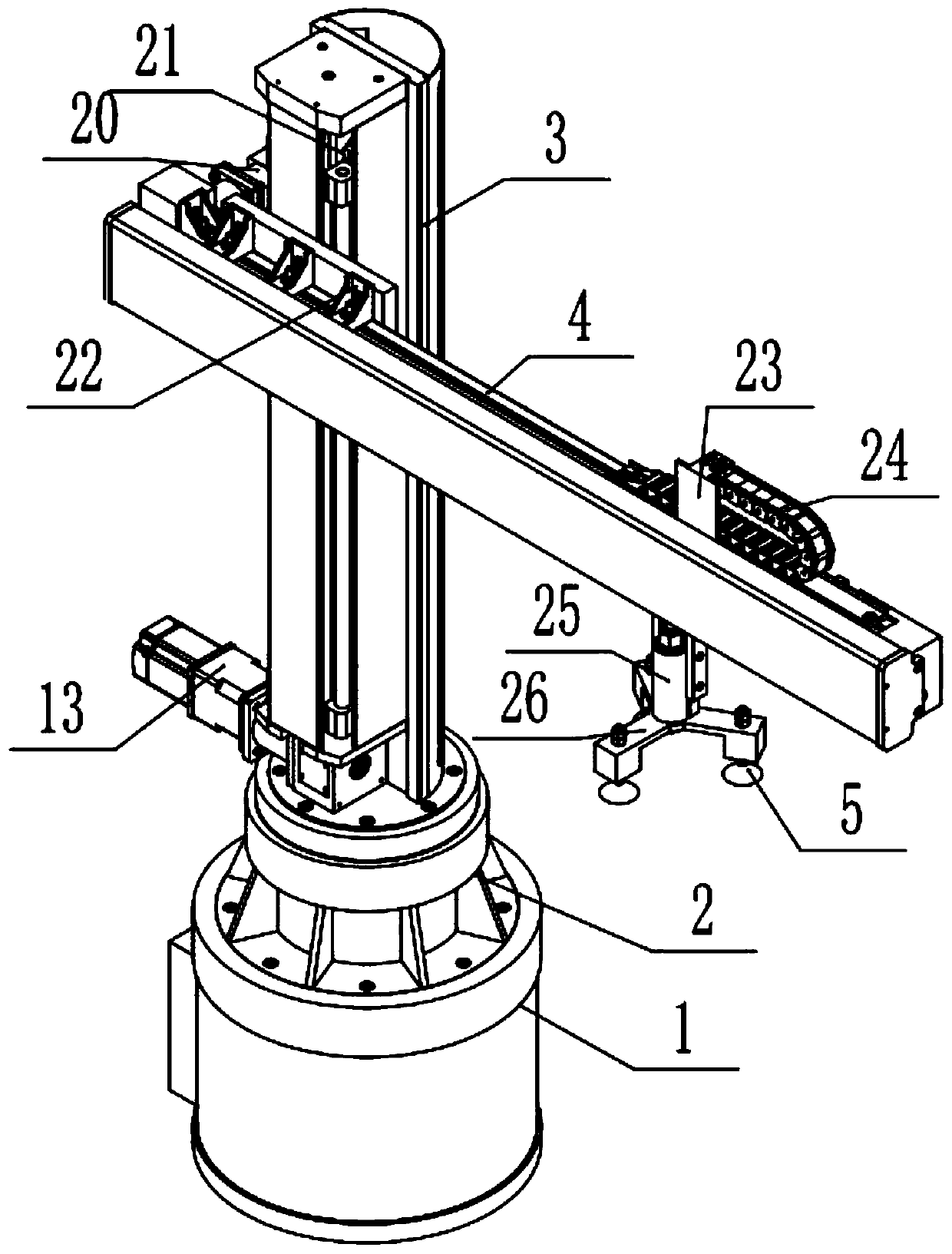

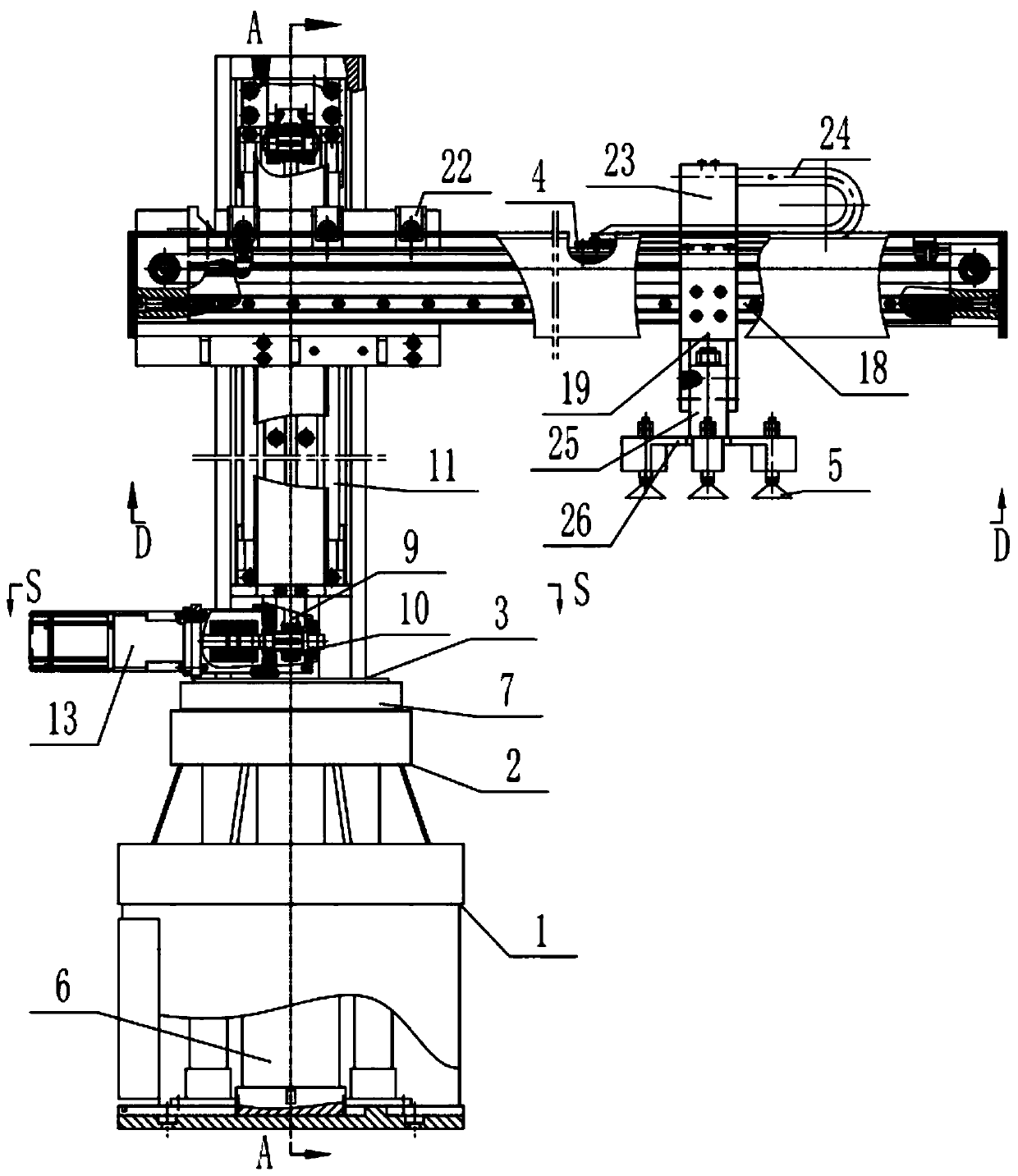

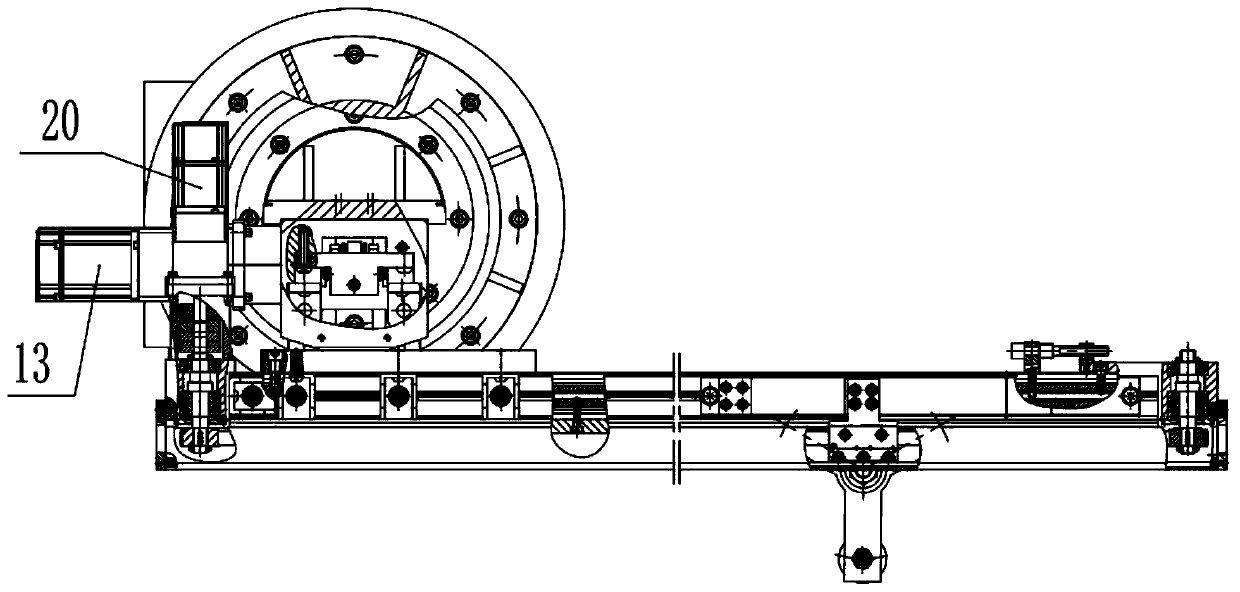

[0029] Embodiment 1: as Figure 1-Figure 6 As shown, a mechanical device for handling electronic device packaging boxes includes a machine base 1, a bearing seat 2, a column 3, a cantilever 4 and a suction cup 5, a bearing seat 2 is installed above the base 1, and the column 3 is rotatably connected to the base 1 The upper and lower ends extend into the base 1 and connect to the rotating motor 6, the rotating motor 6 is fixedly connected to the base 1, the cantilever 4 is connected to the column 3 through an electric lifting mechanism, and the suction cup 5 is connected to the cantilever 4 through a horizontal electric telescopic mechanism up, the direction of suction cup 5 is downward.

[0030] Preferably, the above-mentioned bearing housing 2 includes an I-shaped circular housing 201, a slewing support bearing 202 and a tapered roller bearing 203, and the slewing support bearing 202 and the tapered roller bearing 203 are fixedly connected to the stepped hole and the upper en...

Embodiment 2

[0038]Embodiment 2: An operation method of a mechanical device for transporting electronic device packaging boxes. The method is as follows: the horizontal electric telescopic mechanism adjusts the position of the suction cup according to the position of the electronic device packaging box, so that the suction cup moves to the top of the packaging box, and the electric lifting mechanism Descend to the predetermined height where the suction cup can hold the electronic device packaging box, the suction cup will absorb the electronic device packaging box, the electric lifting mechanism rises to the predetermined height, the horizontal electric telescopic mechanism retracts to a predetermined distance from the axis of the base, and the base rotates to the right 180°, the horizontal electric telescopic mechanism stretches forward to directly above the middle position of the packaging conveyor belt, the electric lifting mechanism descends to the predetermined height that can release t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com