Packaging belt production line

A packaging belt and production line technology, applied in the field of packaging belt production, can solve problems such as improving production efficiency, high cost, and poor production rhythm, and achieve the effects of avoiding slipping or breaking, simplifying the replacement process, and reducing the risk of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

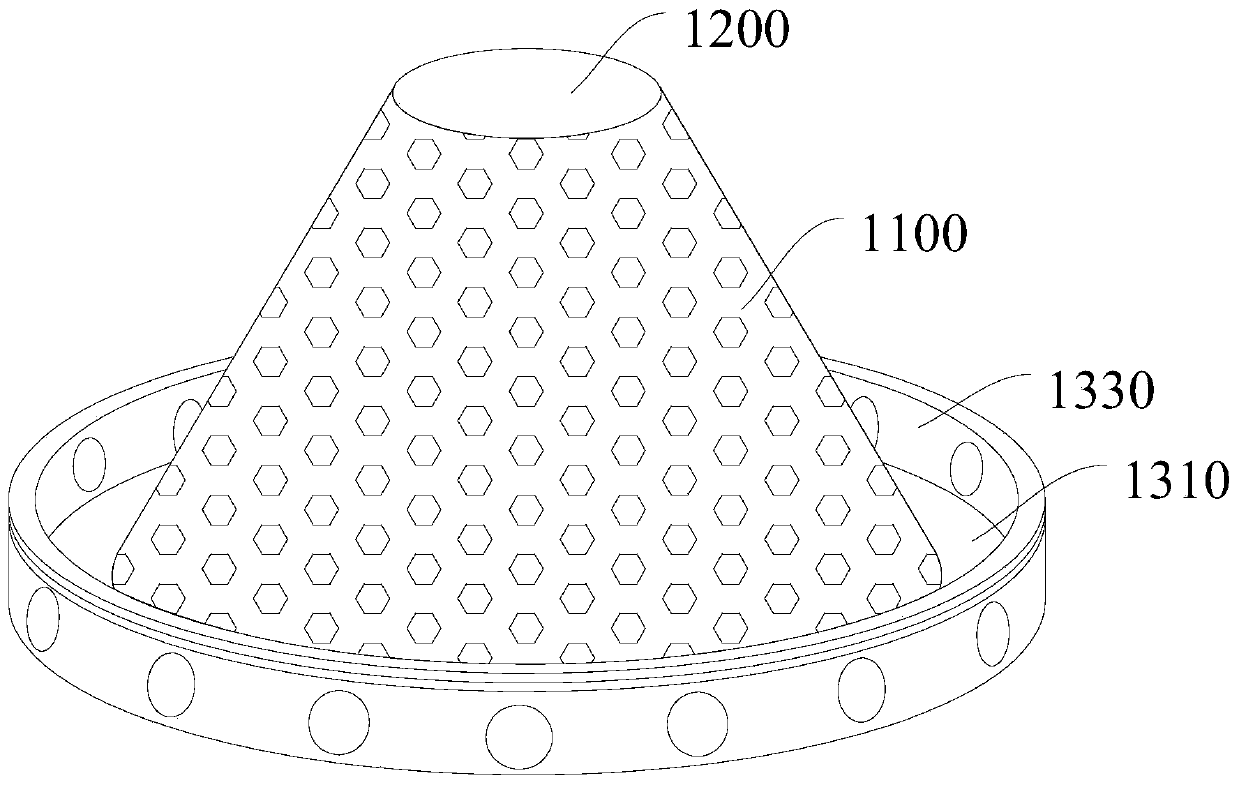

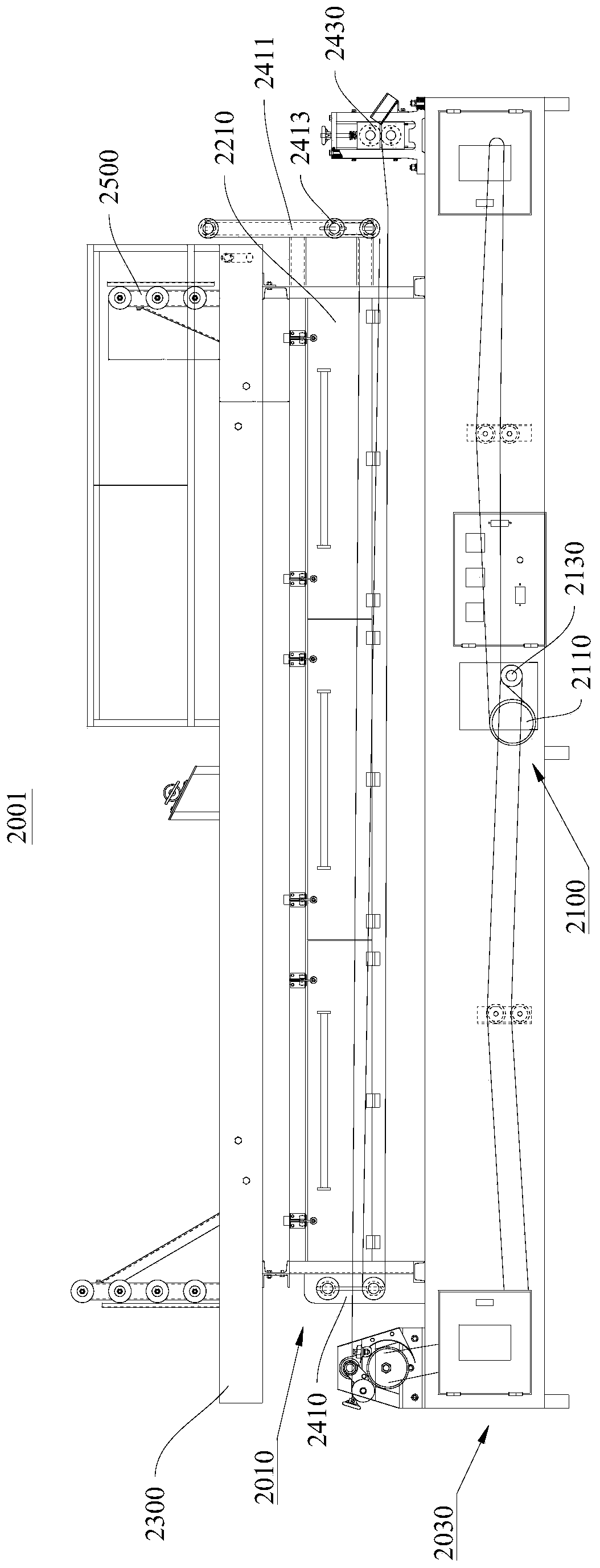

[0060] This embodiment provides a packaging tape production line, which includes a stirring funnel, a melting material mixing drum, a drying device 2001, an embossing device 3001 and a coiling device 4001; the stirring funnel has a material inlet, a material inlet A sieve funnel is arranged at the center, and the sieve funnel is connected with the output end of the vibrator; a mixing auger is also arranged in the mixing funnel; the bottom of the mixing funnel is connected with the entrance of the melting material mixing drum, and a stirring The auger is provided with a constant temperature heating rod on the inner wall of the melting material mixing drum; the outlet end of the melting material mixing drum is provided with a melting material filtering device 1010, and an extrusion head is arranged between the outlet of the melting material filtering device 1010 and the water cooling pool; the water cooling The outlet end of pool is connected with drying device 2001, and drying d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com