High-reliability application printed circuit board assembly QFN assembling and welding pretreatment method

A printed circuit board, pretreatment technology, applied in printed circuits, manufacturing tools, welding equipment, etc., can solve the problems of low reliability of QFN solder joints, prone to false soldering, etc., to shorten the production cycle, uniform tinning, The effect of improving yield and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further illustrated below by specific examples. However, these examples are only for illustrating the present invention and are not intended to limit the scope of the present invention.

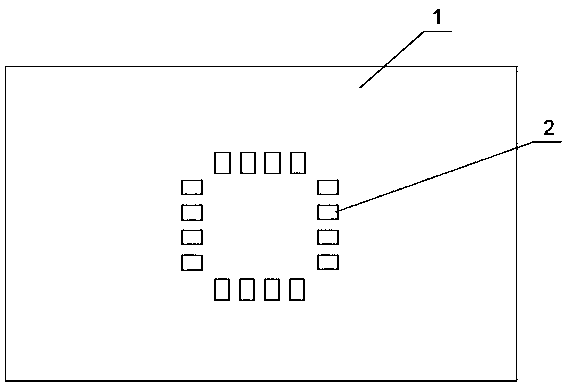

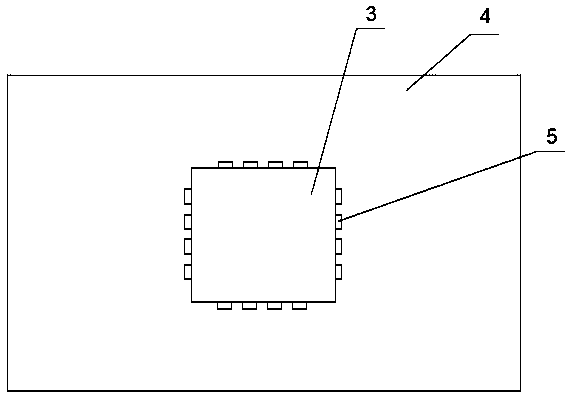

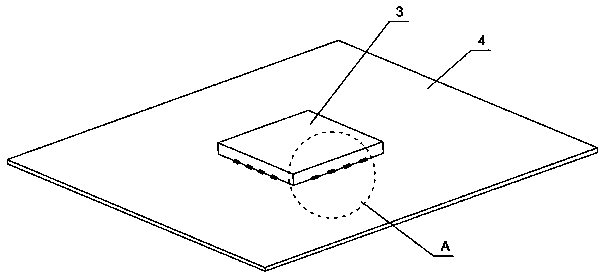

[0033] Combined with the manual Figure 1-5 , a method for pre-tinning a QFN pad, comprising the following steps:

[0034] Step 1), making the carrier board 4 for pre-tinning of the QFN chip pad 6, the carrier board 4 is a composite layer structure, and the carrier board 4 is a solder resist layer 9, an FR-4 ring from top to bottom Oxygen board 7, copper foil layer 8 and FR-4 epoxy board 7; Wherein, described solder resist layer 9 is the level of printing solder paste 5; This design is to meet the needs of this method, requires the carrier board to be flat, and the carrier board surface It is not combined with solder, and the substrate does not deform during heating up to 245°C, while considering the convenience of processing, low cost and reusability. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com