Compressed air foam sprayer used for high-risk complex environment

A technology of compressed air foam and complex environment, which is applied in fire rescue and other directions, and can solve the problems of restricting the application environment of compressed air foam fire extinguishing system, lack of simultaneous prevention and control in different directions, difficulty in adapting to installation protection requirements, etc., and achieve a higher medium distribution density For consistency, easy disassembly, and improved fit performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

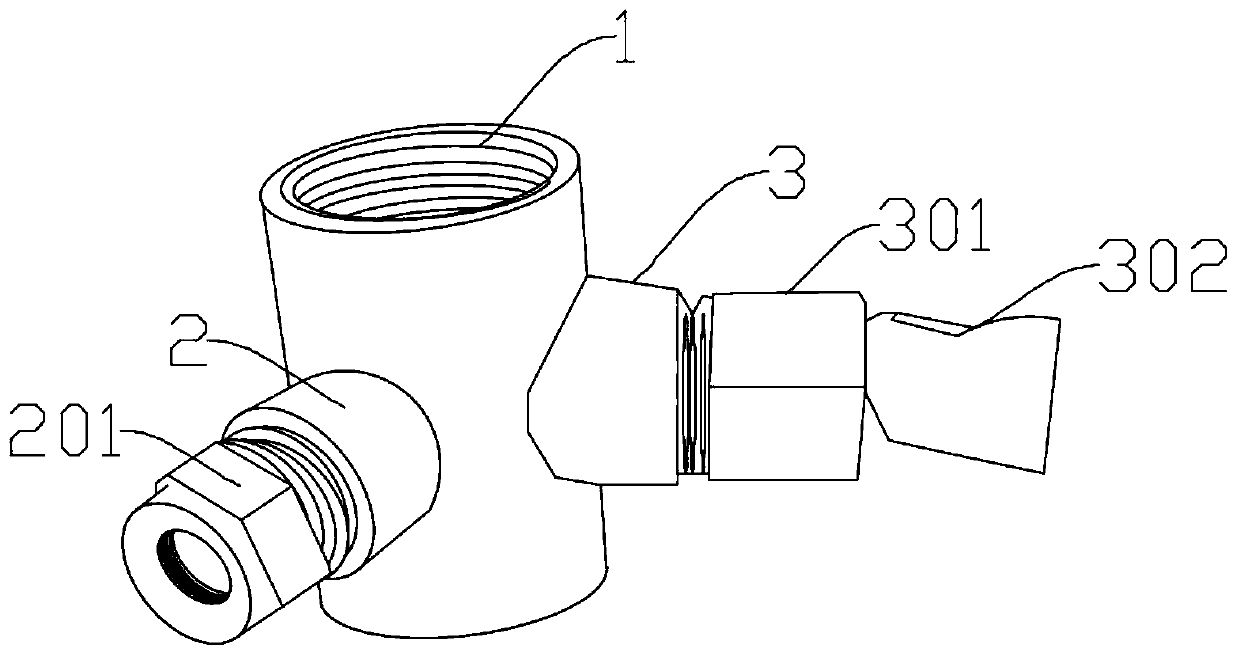

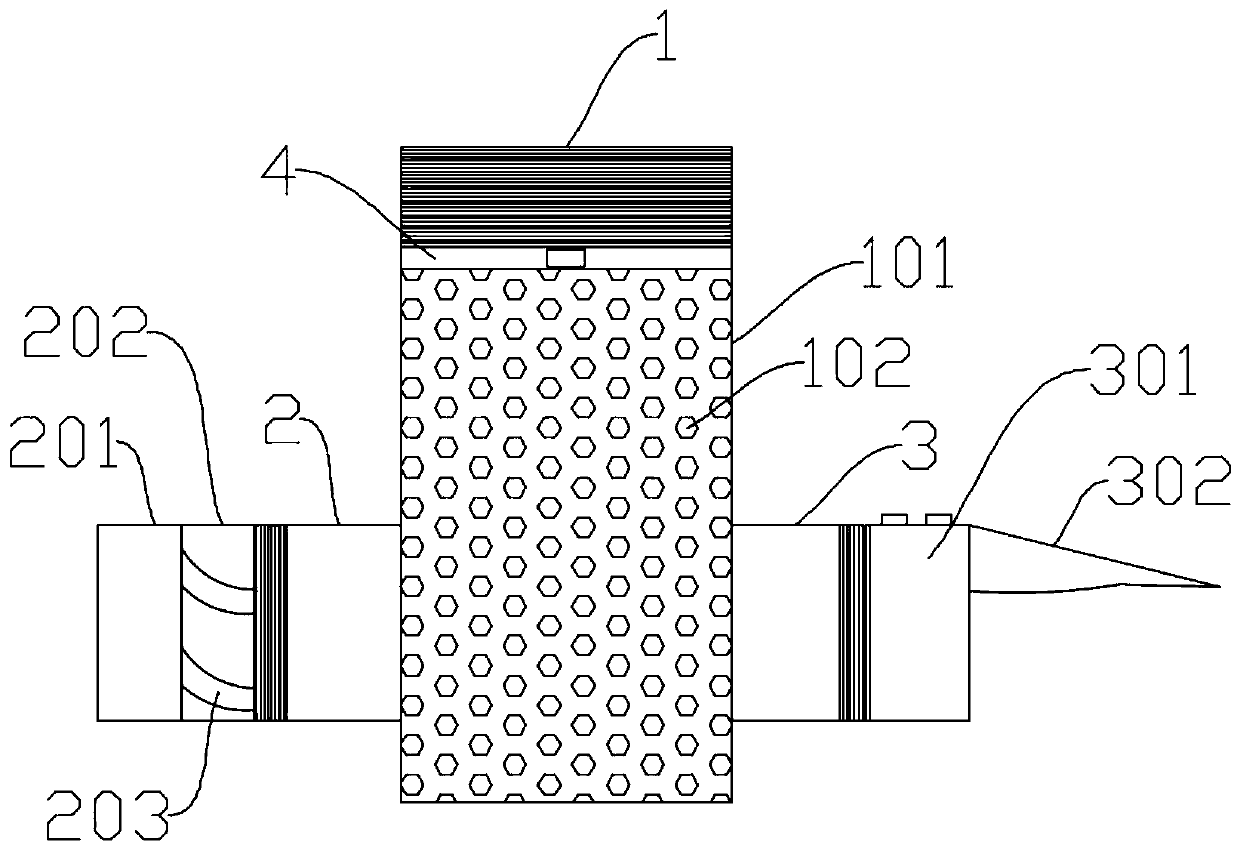

[0032] Such as figure 1 , 2 As shown, a compressed air foam spray head for high-risk complex environments includes a spray head body, one end of the spray head body is provided with a liquid inlet 1, and the other end is a closed end, and the side wall of the spray head body is at least provided with a first liquid outlet port 2 and the second liquid outlet 3, the inside of the spray head body is provided with a mixing chamber, the mixing chamber communicates with the liquid inlet 1, the first liquid outlet 2, and the second liquid outlet 3; The inner wall of the mixing chamber is provided with a foam divider 101 .

[0033] Compared with a single nozzle, the distribution density of the medium at each point after the compressed air foam output of the present invention is more consistent, avoiding the blind area phenomenon that is easy to occur when suppressing a large-scale fire area, forming a single-point multi-directional fire suppression effect, which is conducive to impro...

Embodiment 2

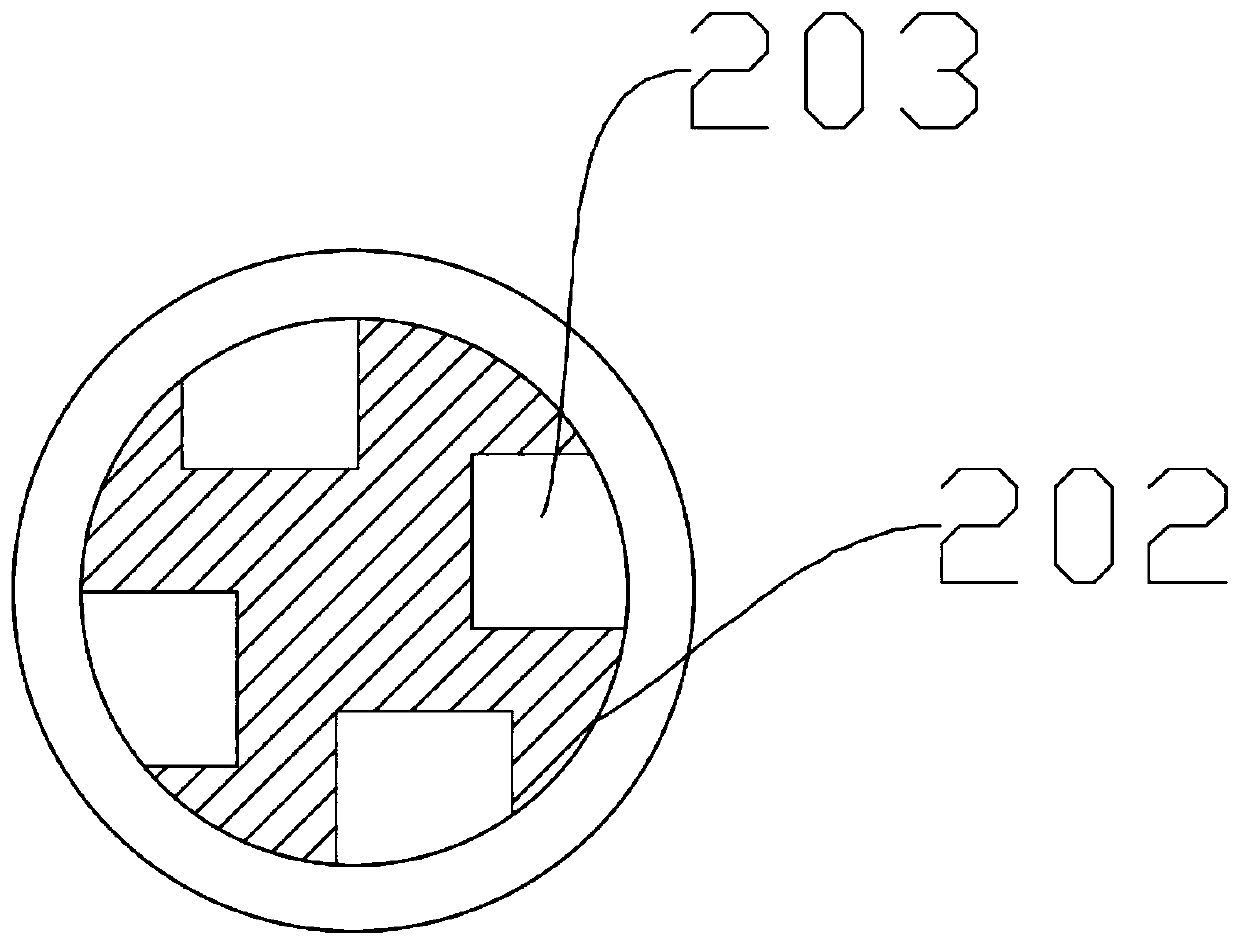

[0035] This embodiment is a further optimization made on the basis of Embodiment 1, as Figure 2-6 As shown, specifically, the first liquid outlet 2 is threadedly connected with a centrifugal nozzle, and the centrifugal nozzle includes a nozzle pipe 201 and a centrifugal spray piece located inside the nozzle pipe 201, and the centrifugal spray piece includes a spray screw body 202. A number of vortex grooves 203 are opened on the side wall of the spray screw body 202 .

[0036] Specifically, the vortex grooves 203 are spirally distributed on the side wall of the spray screw body 202 .

[0037] The vortex grooves 203 are provided with 2-6 pieces. In this embodiment, 4 vortex grooves are provided, which can make the foam spray out in a radiating shape and further increase the coverage area of the foam.

Embodiment 3

[0039] This embodiment is further optimized on the basis of Embodiment 2. Specifically, the foam divider 101 includes a hollow cylindrical panel adapted to the inner wall of the mixing chamber, and the side wall of the hollow cylindrical panel is provided with Several split holes 102;

[0040] Specifically, the diameter of the partition hole 102 is 3-10mm, preferably 5mm, and this setting can divide the compressed air foam into fine foam flows. If the hole diameter is too large or too small, it will greatly affect the expansion ratio, thereby affecting Foaming quality, the foam sprayed by the nozzle of the present invention has good stability, which solves the problem of uniform distribution of multi-point density of the compressed air foam fire extinguishing medium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com