Environment-friendly dense electric tobacco curing room

A tobacco flue-curing room and environmental protection technology, which is applied in the field of flue-cured tobacco room and environment-friendly dense flue-cure room, can solve the problems of difficult precise control of temperature, low utilization rate of heating furnace, and low utilization rate of heat energy, so as to ensure the quality of baking, reduce heat loss, The effect of high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings, but the protection content of the present invention is not limited thereto.

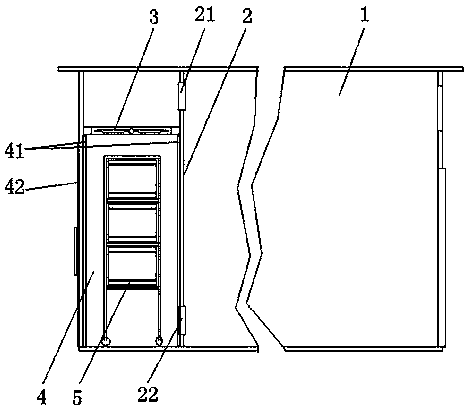

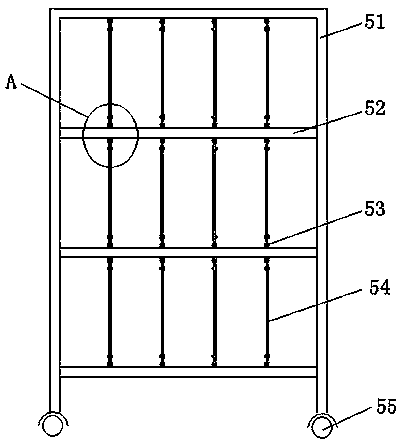

[0030] The environment-friendly dense flue-cured room provided by the present invention includes a flue-cured room 1 for placing tobacco leaves, a heating room 4 communicated with the flue-cured room 1 through airflow passages 21, 22, a fan 3 arranged above the heating room 4, and a An electric heating device 5, the electric heating device 5 includes several electric heating bodies 54 movable on the fixed frame, each electric heating body 54 includes an electric heating film 541 and a carrier 542 attached to the electric heating film 541, and the electric heating film 541 Both ends are provided with flexible conductive strips 543, and each flexible conductive strip 543 is provided with a binding post 544. The binding post 544 is connected to one end of a wire 545, and the other end of the conduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com