Electromagnetic fixation machine with variable magnetic field

A greening machine, variable technology, applied in the direction of tea treatment before extraction, induction heating, induction heating device, etc., to achieve the effect of improving life, reducing processing and procurement costs, and reducing requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

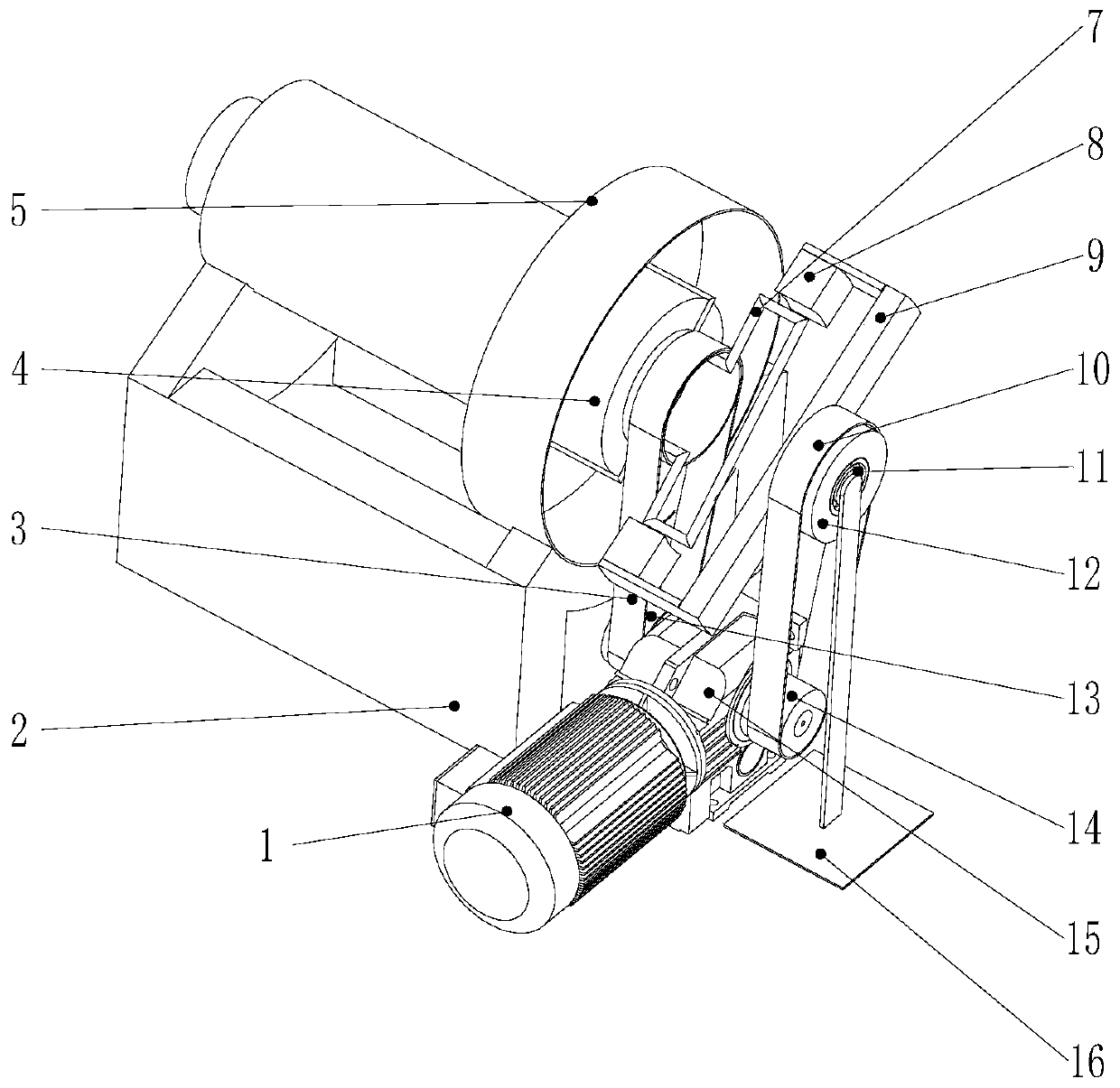

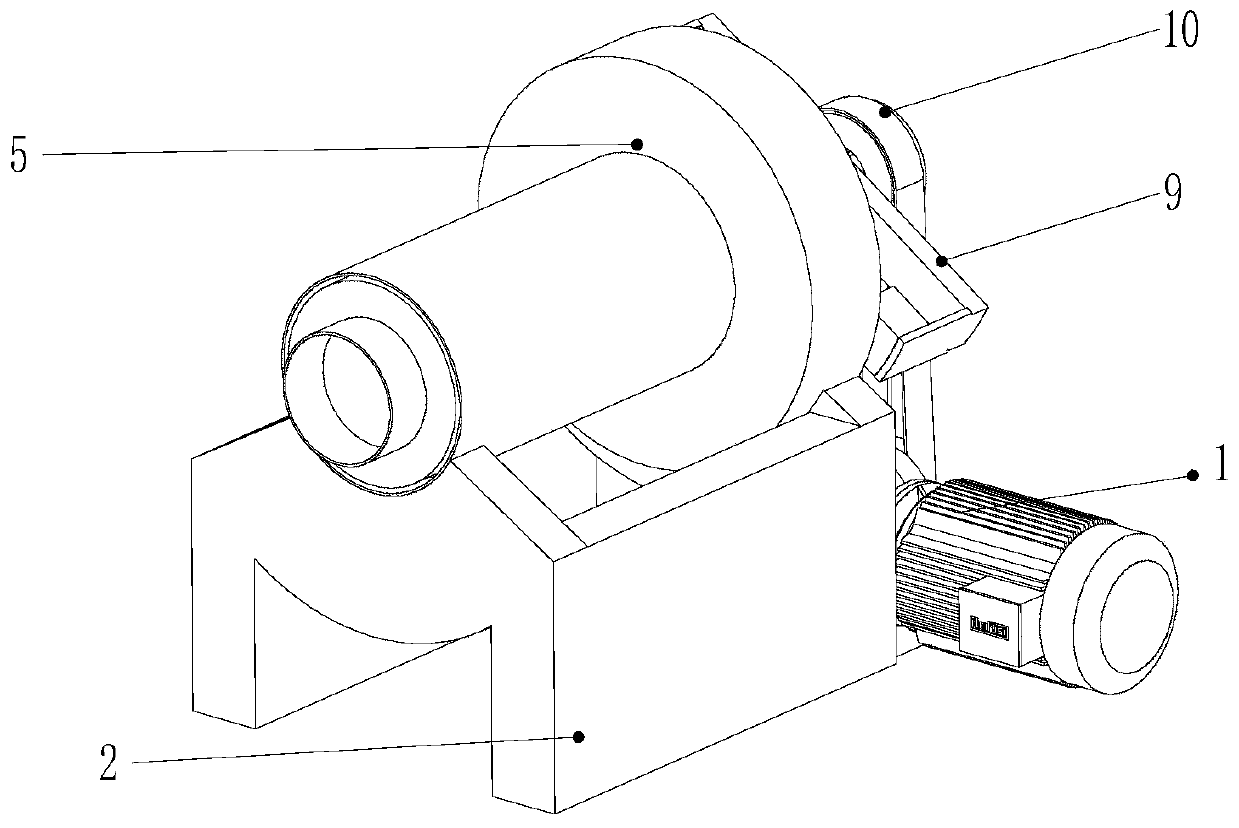

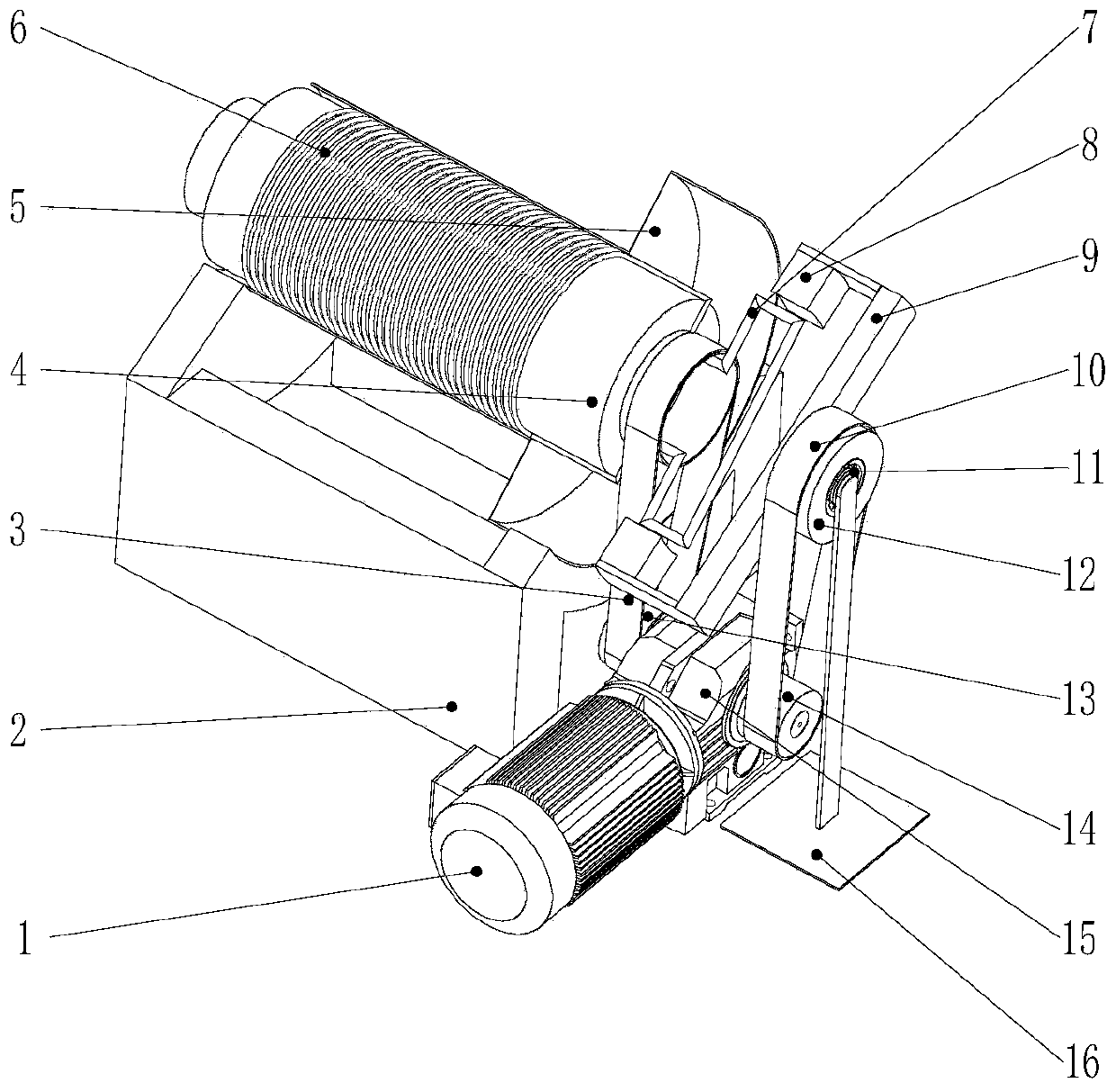

[0039] The present invention will be further described below in conjunction with accompanying drawing:

[0040] Such as Figure 1~5 As shown, an electromagnetic greening machine with variable magnetic field includes a drive motor 1, a frame 2, a first belt 3, a second belt 10, a drum 4, a housing 5, a helical coil 6, a conductor 7, a permanent magnet 8, The permanent magnet fixture 9 , the first driving pulley 13 , the second driving pulley 14 , the rotating disk 12 , the supporting base 16 and the reduction box 15 , the drive motor 1 . Both the support base 16 and the frame 2 are fixed on the horizontal ground, the housing 5 is installed horizontally on the frame 2, the drum 4 is set in the housing 5, and the two ends of the drum 4 are supported on the inner wall of the housing 5 by bearings Above, one end of the drum 4 is provided with a drive shaft; the output shaft of the drive motor 1 is connected to a reduction box 15, and the reduction box 15 is provided with two outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com