Enhanced reactive magnesia cement-based concrete mixes

A technology of magnesium oxide and magnesium hydroxide, applied in the production of magnesium oxide, magnesium hydroxide, cement, etc., can solve the problems of low reactivity and availability, low reaction degree, low diffusion rate, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0146] Example 1: Materials

[0147] The primary cement binder used in the various examples herein was RMC (trade name "calcined magnesite 92 / 200") produced at approximately 1000°C obtained from Richard Baker Harrison, UK. 200)"). The chemical and physical properties of RMC are shown in Table 1 below.

[0148] Table 1-The chemical composition and physical properties of RMC

[0149]

[0150] *R 2 o 3 : Fe 2 o 3 and Al 2 o 3

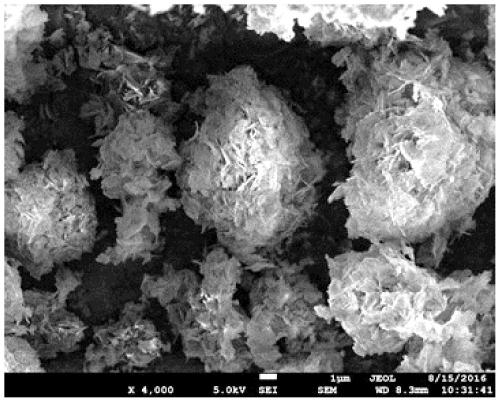

[0151] The reactivity of the RMC (ie, measured by the time required to neutralize 0.25M acetic acid with 5 grams of RMC) was recorded as 520 seconds. Magnesium acetate ((CH 3 COO) 2 Mg) acts as HA to facilitate the hydration process. Using a specific surface area obtained from Fisher Scientific (Fisher Scientific, UK) with a specific surface area of 43.5 m 2 / g hydromagnesite seeds to provide additional nucleation sites and stimulate the nucleation and growth of HMCs in the pore space. figure 1 The microstructure of hydromagnesite see...

Embodiment 2a

[0152] Example 2a: General Example of the Process of the Invention

[0153] The method of the present invention first prepares a solution by dissolving a predetermined amount of HA in water (for example, at a concentration of 0M to 0.1M), and then seeds (for example, 0 weight percent (wt%) to 2wt% magnesium oxide-based cement and seeds) were introduced into the solution. The seeds were allowed to disperse in the solution by stirring using a magnetic stirrer at ambient temperature (eg, 30±3°C) for 5 minutes. When subsequently added to the RMC, the seeds in the solution were stirred to allow them to disperse evenly within the pores of the RMC. The well mixed solution can then be introduced into the RMC to form a paste. In some cases, coarse aggregate can then be added to the paste to complete the production of the concrete mix. The cast samples were then compacted and subjected to carbonization.

Embodiment 2b

[0154] Example 2b: General Characterization

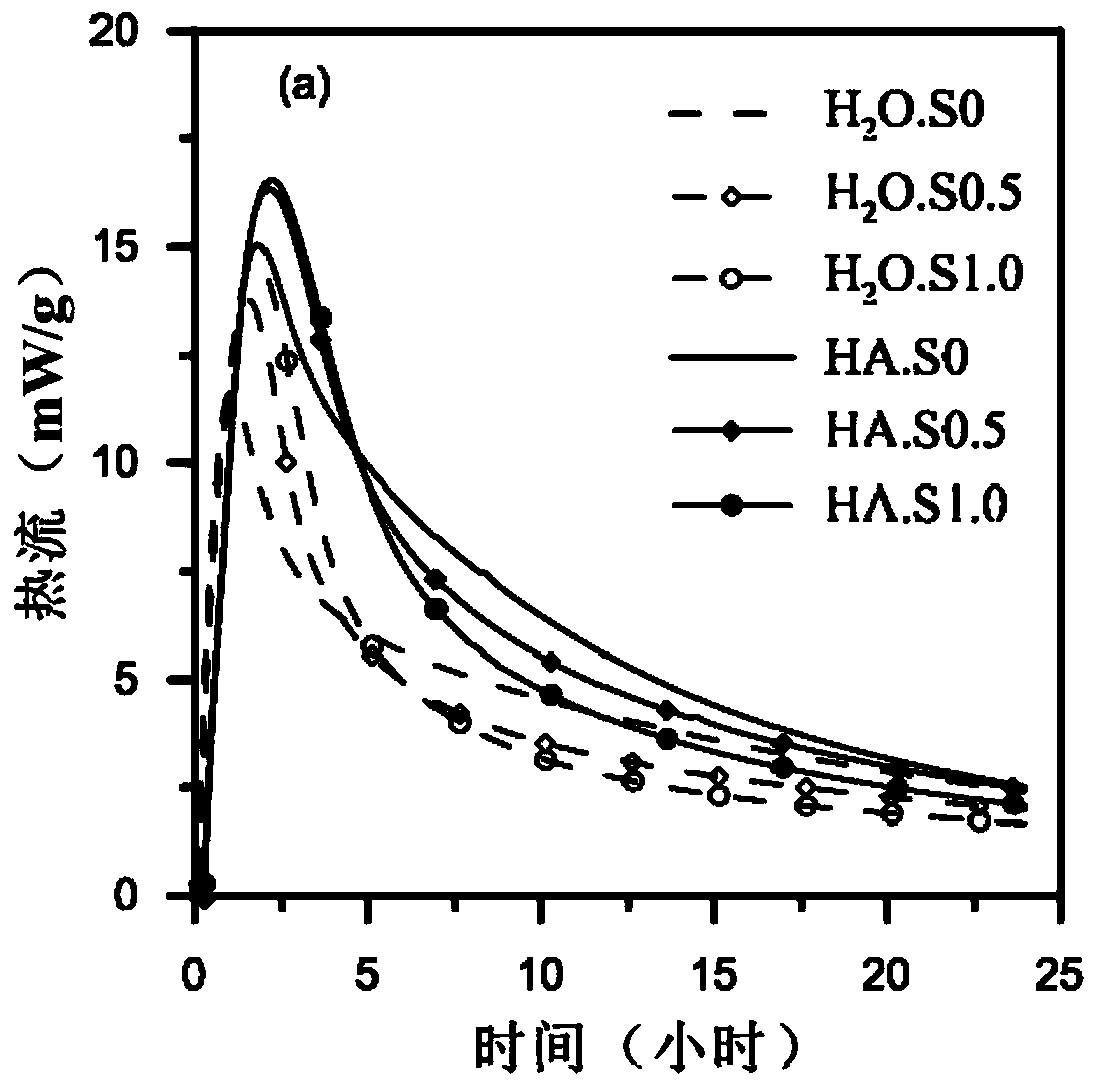

[0155] Isothermal calorimetry characterization was performed on the samples in each of the examples below. The heat flow due to the hydration of each mixture was studied at 30°C by an I-Cal 8000 high precision calorimeter according to ASTM C1702-15a. The preparation of the paste involves dispersing the seed crystals in H 2 O or HA, the H 2 O or HA was preheated to 30 °C in order to produce samples at the same temperature as the measurement temperature. The seeded solution was then mixed with RMC. After mixing for about 15 to 20 seconds, the prepared paste was placed into an isothermal calorimeter channel to measure the heat of hydration.

[0156] For the water absorption test, each sample was measured after 14 and 28 days of carbonization. Record the initial mass of the sample before immersing it in the water tank. Absorbent mass is also measured when the sample reaches a constant mass under water, which reflects its abilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com