Nano silver wire flexible transparent conductive film with high lapping efficiency and excellent bending resistance

A technology of transparent conductive film and nano-silver wire, which is applied to the conductive layer, conductor, circuit, etc. on the insulating carrier, which can solve the problems of poor electrical performance, poor compactness, and low welding window of the conductive film, and achieve improved bending resistance. , improved bending resistance, and improved lap joint efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The formula of the conductive ink for the nano-silver wire transparent conductive film of this embodiment is as follows:

[0054] Nano silver wire (WJAG1) 0.13%

[0055] Dispersion film-forming aid (hydroxyethyl cellulose) 0.2%

[0056] Deionized water 0ppm 99.67%

[0057] Specific preparation method: add deionized water, nano-silver wire WJAG1 (wire diameter 20nm, aspect ratio 1000-2000, Hefei Microcrystalline Material Technology Co., Ltd.), hydroxyethyl cellulose into the dispersion tank in sequence, and at a speed of 500r / min Stir for 30min to prepare conductive ink.

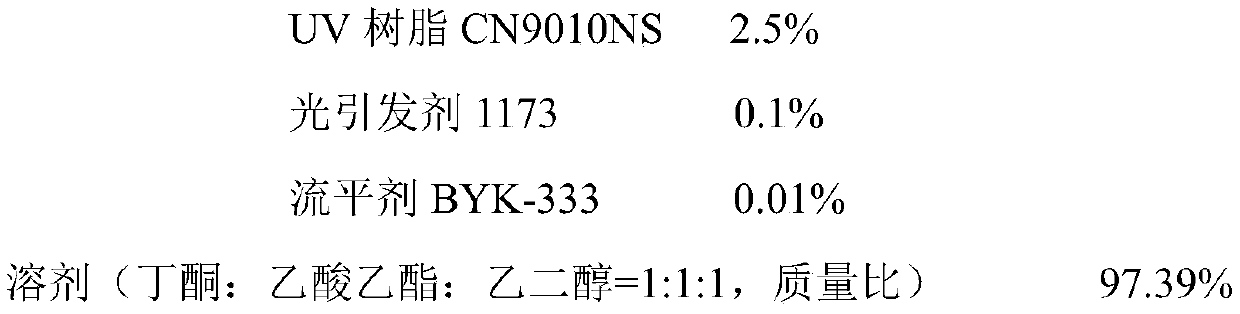

[0058] The formulation of optimization solution for silver nano wire transparent conductive film in this embodiment is as follows:

[0059] Methyl magnesium bromide 1 part

[0060] Ethylene glycol 1 part

[0061] Solvent (ethanol, isobutanol, ethyl acetate mass ratio 1:1:1) 98 parts

[0062] Specific preparation method: add methylmagnesium bromide, ethylene glycol, and solvent in sequence to the ...

Embodiment 2

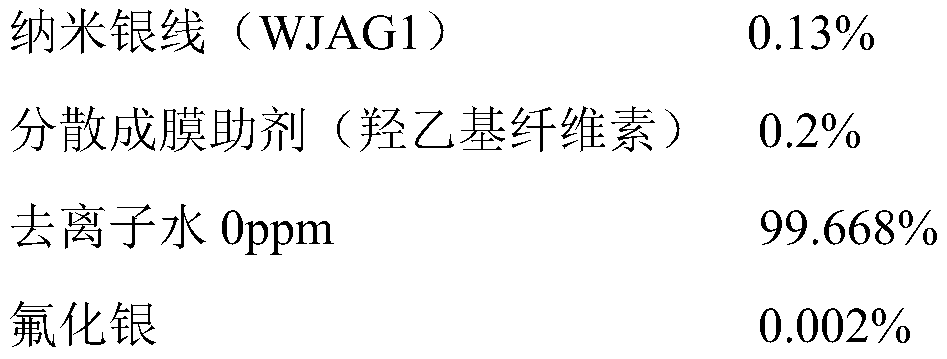

[0068] The formula of the conductive ink for the nano-silver wire transparent conductive film of this embodiment is as follows:

[0069]

[0070] Specific preparation method: add deionized water, nano-silver wire WJAG1 (wire diameter 20nm, aspect ratio 1000-2000, Hefei Microcrystalline Material Technology Co., Ltd.), hydroxyethyl cellulose, and silver fluoride to the dispersion tank in sequence, and Stir at 500r / min for 30min to prepare conductive ink.

[0071] The formulation of optimization solution for silver nano wire transparent conductive film in this embodiment is as follows:

[0072] Methyl magnesium bromide 1 part

[0073] Ethylene glycol 1 part

[0074] Solvent (ethanol, isobutanol, ethyl acetate mass ratio 1:1:1) 98 parts

[0075] Specific preparation method: add methylmagnesium bromide, ethylene glycol, and solvent in sequence to the dispersion tank, and stir at 500r / min for 30min to obtain the optimized solution.

[0076] Preparation of transparent conducti...

Embodiment 3

[0081] The formula of the conductive ink for the nano-silver wire transparent conductive film of this embodiment is as follows:

[0082]

[0083] Specific preparation method: Add deionized water, nano-silver wire WJAG1 (wire diameter 20nm, aspect ratio 1000-2000, Hefei Microcrystalline Material Technology Co., Ltd.), hydroxyethyl cellulose, and silver nitrate into the dispersion tank in sequence, and use 500r / min speed stirring for 30min to prepare the conductive ink.

[0084] The formulation of optimization solution for silver nano wire transparent conductive film in this embodiment is as follows:

[0085] Methyl magnesium bromide 1 part

[0086] Ethylene glycol 1 part

[0087] Solvent (ethanol, isobutanol, ethyl acetate mass ratio 1:1:1) 98 parts

[0088] Specific preparation method: add methylmagnesium bromide, ethylene glycol, and solvent in sequence to the dispersion tank, and stir at 500r / min for 30min to obtain the optimized solution.

[0089] Preparation of tra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com