Method for detecting irregular defect of industrial product

An irregular, industrial technology, applied in image data processing, instruments, biological neural network models, etc., can solve problems such as high computing power requirements, limited computing power, and poor product detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

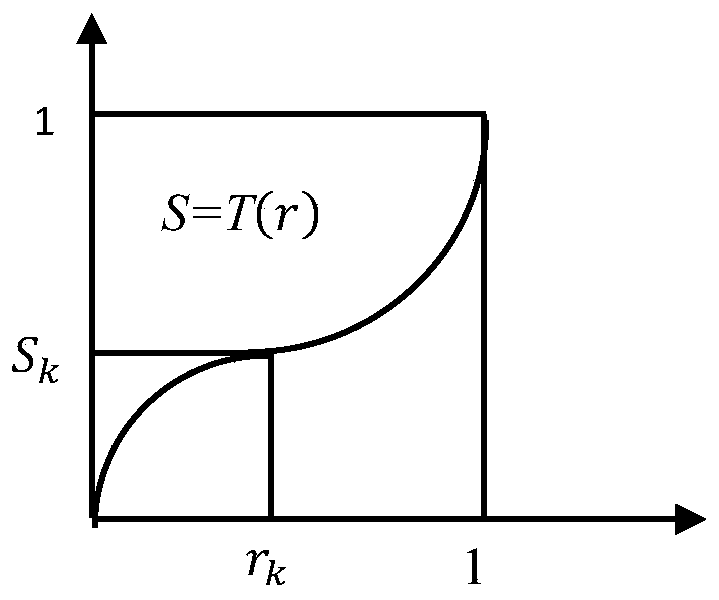

[0101] In order to overcome the above-mentioned shortcomings of the prior art, the present invention provides a method for detecting irregular defects of industrial products based on deep learning for some irregular defect problems. Firstly, image enhancement processing is performed on the collected sample images to make the defects more obvious; then, based on the convolutional neural network (CNN), combined with the SSD target recognition model, the defect detection network model is constructed, and the model parameters are designed reasonably, which can effectively solve the problem. The detection puzzle of rule flaws.

[0102] To achieve the above object, the present invention adopts the following technical solutions:

[0103] A method for detecting irregular defects of industrial products, comprising the steps of:

[0104] Step 1, image enhancement processing;

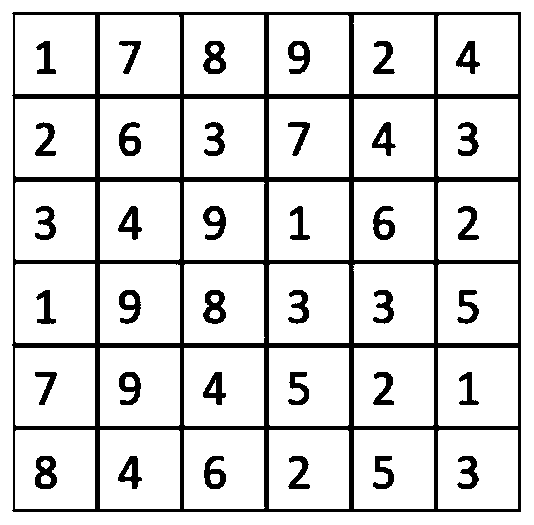

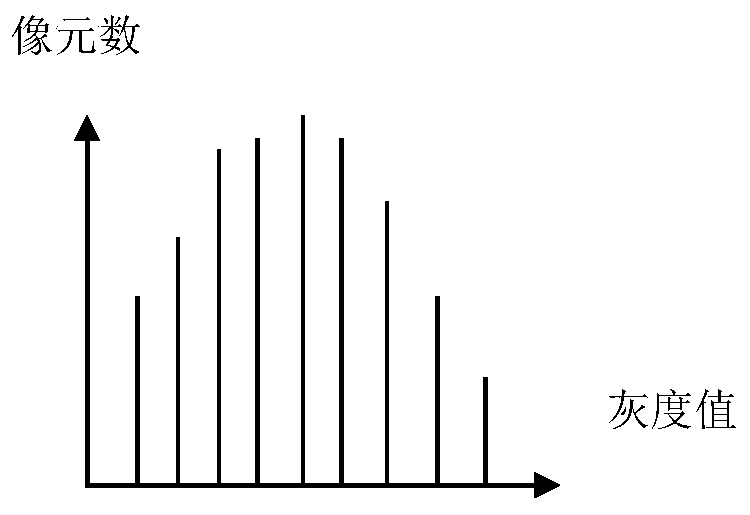

[0105] The image grayscale histogram describes the number of pixels with the grayscale in the image. Usually...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com