A kind of preparation method of single crystal copper foil

A technology of copper foil and single crystal, which is applied in the field of static preparation of large-area single crystal copper foil, can solve the problems of complicated process and equipment, and achieve the effect of convenient large area, simple process and high single crystal degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

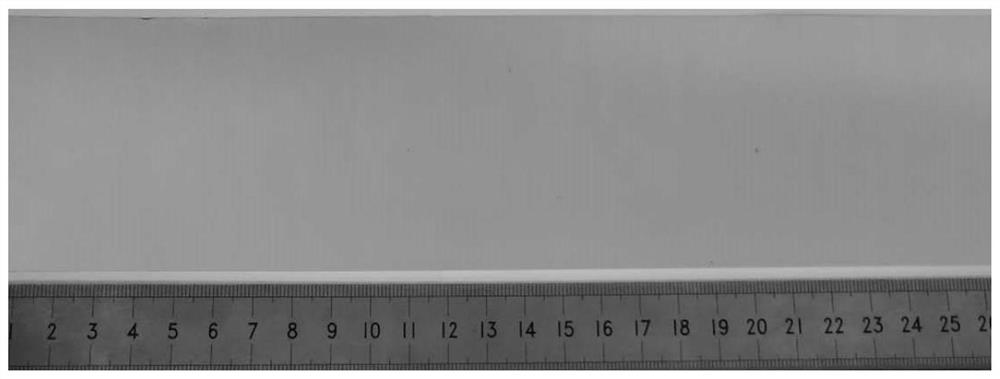

Image

Examples

preparation example Construction

[0057] A method for preparing a single crystal copper foil according to an embodiment of the present invention includes the following steps:

[0058] S1: placing the polycrystalline copper foil on the carrier;

[0059] S2: placing the carrier with the copper foil in the annealing furnace;

[0060] S3: Raise the temperature of the annealing furnace to the specified temperature to form an annealing area with multiple temperature zones, and perform high-temperature annealing on the polycrystalline copper foil;

[0061] S3: cooling the annealing furnace to room temperature to obtain a single crystal copper foil sample.

[0062] According to the method of one embodiment of the present invention, by configuring multiple carriers, multiple pieces of polycrystalline copper foil can be annealed at one time, so as to achieve static preparation of single crystal copper foil in batches.

[0063] The method of this embodiment has no specific requirements on the shape of the polycrystalli...

Embodiment 1 3

[0067] Example 1 Annealing in a three-temperature zone annealing furnace to obtain a monolithic single crystal copper foil

[0068] In this embodiment, the annealing furnace used is a three-temperature zone annealing furnace. The length of each temperature zone is 20cm. The temperature settings of the three temperature zones are: 1020°C, 1000°C, 980°C. The specific steps are:

[0069] (1) Cut a single piece of industrial copper foil into a length of 40 cm, place it on a copper foil carrier, and place the copper foil carrier in an annealing furnace so that the copper foil is in three temperature zones;

[0070] (2) Turn on the mechanical pump to evacuate the annealing furnace, and then feed 500 sccm hydrogen;

[0071] (3) Raise the temperature of the three temperature zones of the annealing furnace to the set temperature: 1020°C, 1000°C, 980°C;

[0072] (4) Anneal the copper foil at the set temperature for 30 minutes;

[0073] (5) After the temperature of the annealing fur...

Embodiment 2 3

[0074] Example 2 Annealing in a three-temperature zone annealing furnace to obtain multiple batches of single crystal copper foil

[0075] In this embodiment, the annealing furnace used is a three-temperature zone annealing furnace. The length of each temperature zone is 20cm. The temperature settings of the three temperature zones are: 1020°C, 1000°C, 980°C. The specific steps are:

[0076] (1) Cut multiple pieces of industrial copper foil into 45cm long, place each piece of copper foil on a copper foil carrier, stack the copper foil carrier vertically, and then place it in an annealing furnace so that the copper foil is in three In the temperature zone;

[0077] (2) Turn on the mechanical pump to evacuate the annealing furnace, and then feed 500 sccm hydrogen;

[0078] (3) Raise the temperature of the three temperature zones of the annealing furnace to the set temperature: 1020°C, 1000°C, 980°C;

[0079] (4) Anneal the copper foil at the set temperature for 30 minutes; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com