3D printing special engineering plastic support material and preparation method of wires of support material

A special engineering plastic, 3D printing technology, applied in the field of 3D printing, can solve the problems of easy detachment and deformation of the main material, ironing of the thermal printing layer, unsatisfactory adhesion, etc. Printable, easy-to-prepare effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

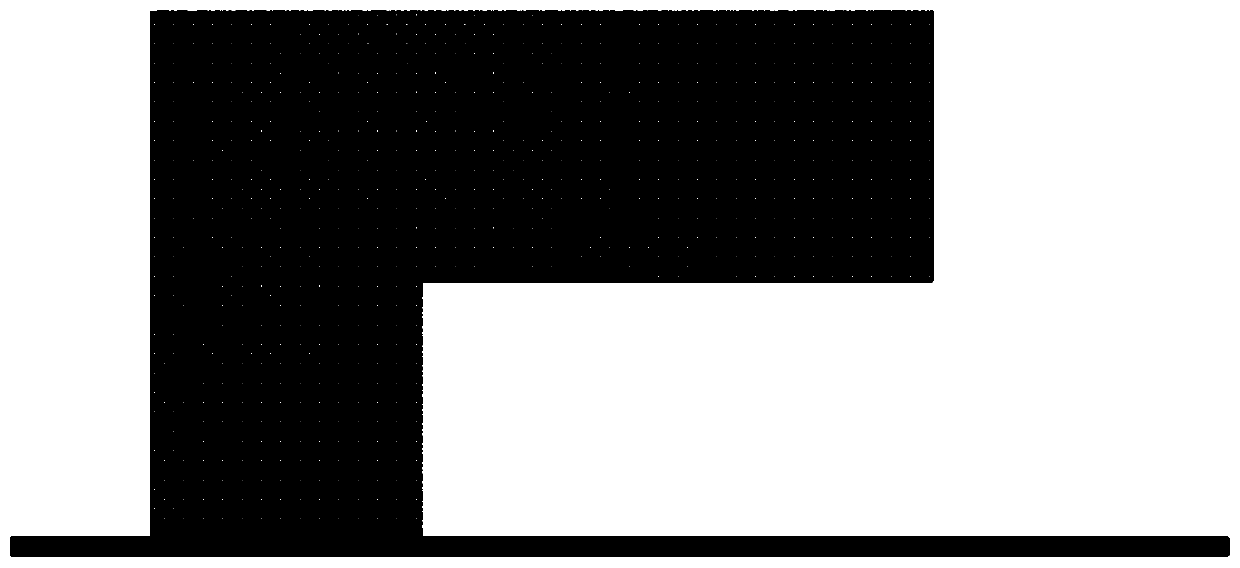

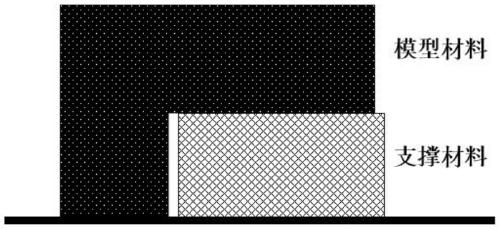

Image

Examples

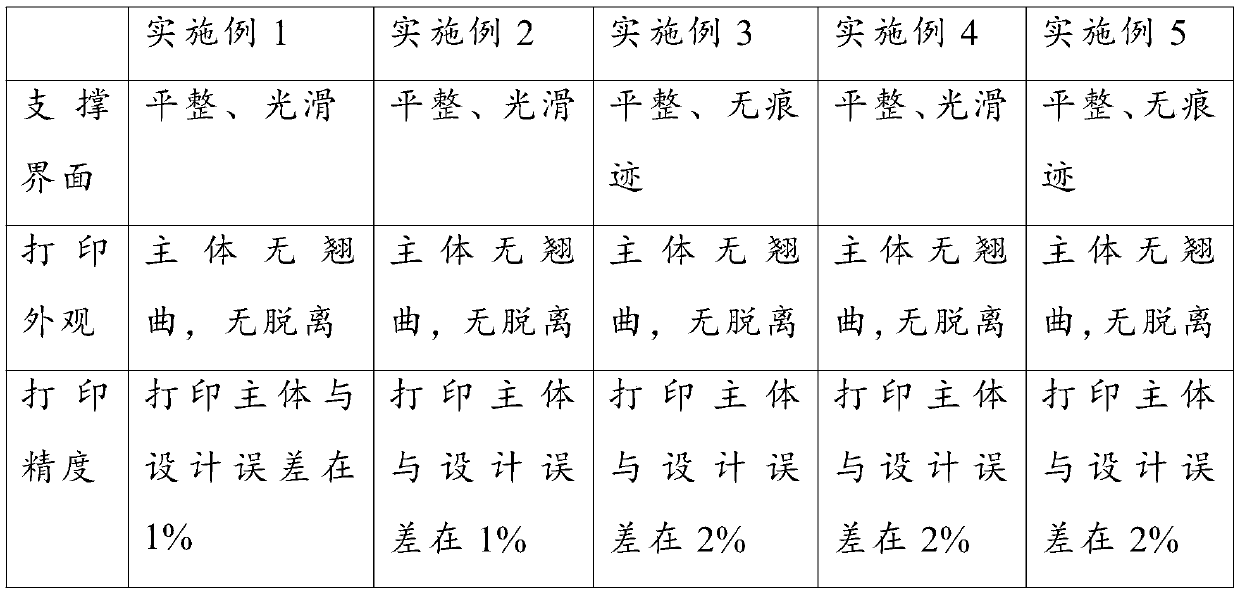

Embodiment 1

[0043] 75 parts of polycarbonate resin, 15 parts of carbon fiber, 5 parts of silane coupling agent, 4.5 parts of trioctyl trimellitate, 0.5 part of antioxidant 1010 and 168 (the mass ratio of 1010 and 168 is 2:1) in Mix in a high-speed mixer at 60°C for 15 minutes, and the mixed material is extruded through a twin-screw extruder (extrusion temperature is 220°C, screw speed is 260r / min), and is supported by air-cooled drag chain cutting Material blend particles.

[0044] The support material blended particles were vacuum-dried at 80°C for 4 hours and then entered into a single-screw extruder for extrusion (extrusion temperature was 250°C, screw speed was 250r / min), and the extruded melt was cooled in a water tank, air-dried and drawn A monofilament wire with a diameter of 1.75 mm was obtained, and the monofilament was wound up and then dried in an oven at 80°C for 6 hours before use, and a special support material wire for 3D printing special engineering plastics was obtained. ...

Embodiment 2

[0047] A blend of 80 parts of polycarbonate (PC) and acrylonitrile-butadiene-styrene copolymer (ABS) (the mass ratio of PC and ABS is 70:30), 10 parts of glass fiber, 8 parts of polycarbonate Ester grafted maleic anhydride, 1.5 parts of dioctyl phthalate, 0.5 parts of antioxidant 1010, 168 and triphenyl phosphate (the mass ratio of antioxidant 1010, antioxidant 168 and triphenyl phosphate is 2 : 1: 1) Mix in a high-speed mixer at 60°C for 15 minutes, and the mixed material is extruded through a twin-screw extruder (extrusion temperature is 180°C, screw speed is 290r / min), and dragged by an air-cooled pull bar. The chain cutting can obtain the support material blended particles.

[0048] The support material blended particles were vacuum-dried at 80°C for 4 hours and then entered into a single-screw extruder for extrusion (extrusion temperature was 190°C, screw speed was 270r / min), and the extruded melt was cooled in a water tank, air-dried and drawn A monofilament wire with a...

Embodiment 3

[0051] 85 parts of polycarbonate (PC) and polyetheretherketone (PEEK) blend (PC and PEEK mass ratio: 80:20), 10 parts of talc (1500 mesh), 3 parts of polyethylene grafted methyl Glycidyl acrylate, the dioctyl phthalate of 1.5 parts, the antioxidant 1010,168 of 0.5 part and triphenyl phosphate (the mass ratio of antioxidant 1010, antioxidant 168 and triphenyl phosphate is 2 : 1: 1) Mix in a high-speed mixer at 60°C for 15 minutes, and the mixed material is extruded through a twin-screw extruder (extrusion temperature is 320°C, screw speed is 290r / min), and dragged by air-cooled pull bar The chain cutting can obtain the support material blended particles.

[0052] The support material blended particles were vacuum-dried at 80°C for 4 hours and then entered into a single-screw extruder for extrusion (extrusion temperature was 350°C, screw speed was 250r / min), and the extruded melt was cooled in a water tank, air-dried and drawn A monofilament wire with a diameter of 1.75 mm was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com