Preparation method of ABA type organosilicone glucoheptonic acid amide surface active agent

The technology of silicon glucoheptonic acid amide and glucoheptonic acid amide siloxane is applied in the field of preparation of ABA type organosilicon glucoheptonic acid amide surfactant, which can solve the problem that the grafting rate of sugar groups is low and the application scope is affected. , poor water solubility of the product, etc., to achieve the effects of high grafting rate, good water solubility, and short use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

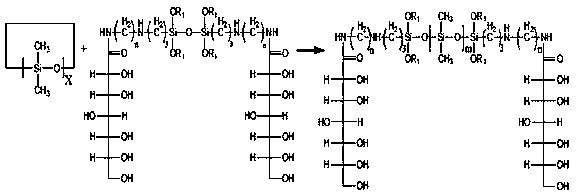

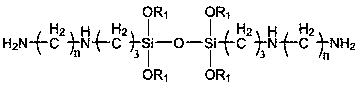

Method used

Image

Examples

Embodiment 1

[0038] Add 20.8g glucoheptonolactone and 39.8g bisaminoethylaminopropyl tetramethoxydisiloxane to the flask, add 100mL methanol as solvent, react at 80°C for 2h, distill methanol off to obtain glucoheptin Sugar acid amide tetramethoxydisiloxane. Add 60.6 g of glucoheptonic acid amide tetramethoxydisiloxane and 3.7 g of eicosyldecaciloxane into the flask, add 0.037 g of tetramethylammonium hydroxide as a catalyst, and react at 90° C. for 4 hours. After the reaction, heat to 134°C to deactivate the catalyst to obtain the silicone glucoheptonic acid amide surfactant. The primary ammonia value was measured by non-aqueous potentiometric titration, and the calculated grafting rate was 95%; the minimum surface tension of the product obtained was 24.3mN / m, the critical micelle concentration was 52mg / L, and the solubility was 75g / 100g water.

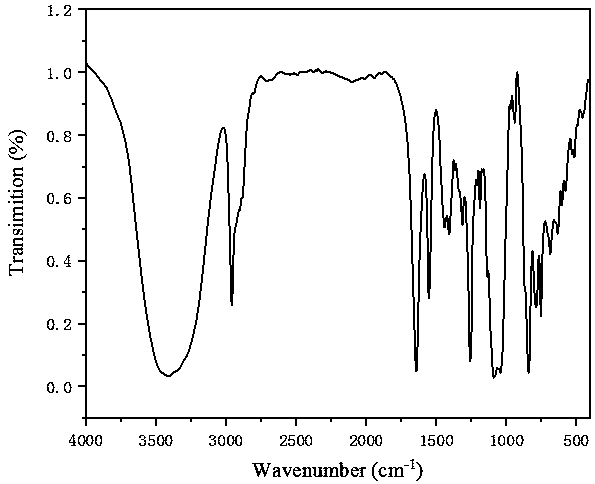

[0039] The obtained product has been detected by infrared spectrum, indicating that the method has prepared an ABA type silicone glucoheptonic ...

Embodiment 2

[0041] Add 20.8g glucoheptonolactone and 39.8g bisaminoethylaminopropyl tetramethoxydisiloxane to the flask, add 140mL ethanol as solvent, react at 90°C for 3h, distill off ethanol to obtain glucoheptin Sugar acid amide tetramethoxydisiloxane. Add 60.6g of glucoheptonic acid amide tetramethoxydisiloxane and 55.5g of hexamethyltrisiloxane into the flask, and add potassium trimethylsiliconate with a mass fraction of 1.5% as catalyst 0.83g, at 85°C Under the reaction 3h. After the reaction, heat to 134°C to deactivate the catalyst to obtain the silicone glucoheptonic acid amide surfactant. The primary ammonia value was measured by non-aqueous potentiometric titration, and the calculated grafting rate was 98%; the minimum surface tension of the product obtained was 22.4mN / m, the critical micelle concentration was 390mg / L, and the solubility was 59g / 100g water.

Embodiment 3

[0043] Add 20.8g glucoheptonolactone and 31.2g bisaminopropyltetramethoxydisiloxane into the flask, add 200mL isopropanol as solvent, react at 95°C for 1.5h, distill and remove isopropanol to obtain Glucoheptonamide Tetramethoxydisiloxane. Add 37.1g of glucoheptonic acid amide tetramethoxydisiloxane and 3.7g of eicosylcyclodecasiloxane into the flask, add 0.037g of potassium trimethylsiliconate as a catalyst, and react at 110°C for 4h . After the reaction is over, add acetic acid to deactivate the catalyst, and filter to obtain the organic silicon glucoheptonic acid amide surfactant. The primary ammonia value was measured by non-aqueous potentiometric titration, and the grafting rate was calculated to be 97.5%; the minimum surface tension of the product obtained was 26.4mN / m, the critical micelle concentration was 740mg / L, and the solubility was 68g / 100g water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface tension | aaaaa | aaaaa |

| Minimum surface tension | aaaaa | aaaaa |

| Minimum surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com