Porous nickel carbide material, preparation method thereof and super capacitor prepared from porous nickel carbide material

A supercapacitor, nickel carbide technology, applied in chemical instruments and methods, hybrid capacitor electrodes, hybrid/electric double-layer capacitor manufacturing, etc., can solve the problems of low freezing point, dangerous operation, complexity, etc., achieve excellent rate performance, easy to enlarge Production, the effect of good specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

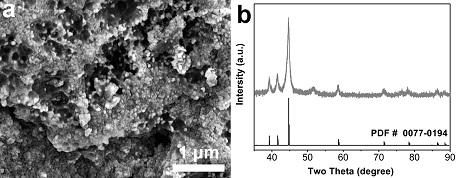

Embodiment 1

[0037] This embodiment provides a method for preparing a porous nickel carbide material, and the preparation steps are as follows:

[0038] (1) Put 1 part of nickel nitrate, 2 parts of citric acid or its salt, and 1 part of sodium chloride in a beaker, add 86 parts of water and 10 parts of ethanol, stir to dissolve;

[0039] (2) Put the above solution in a 40°C constant temperature oil bath for complexation reaction, and slowly precipitate sodium chloride through solvent evaporation method to obtain a gel-state substance coated with sodium chloride;

[0040] (3) Place the above-mentioned beaker containing the gel-state substance in an oven at 80 °C to promote the further cross-linking reaction of citrate and nickel ions, and the decomposition of part of citrate to obtain a fluffy solid powder material;

[0041] (4) Put the above solid powder material in an atmosphere tube furnace at 250 ℃, and perform high-temperature annealing treatment for 1 h in an inert gas protection to pro...

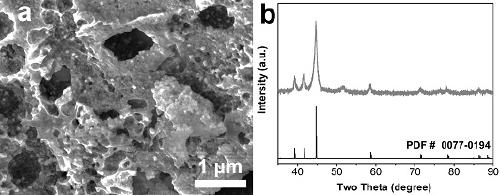

Embodiment 2

[0045] This embodiment provides a method for preparing a porous nickel carbide material, and the preparation steps are as follows:

[0046] (1) Put 1 part of nickel nitrate, 1 part of nickel chloride, 1 part of citric acid, 1 part of sodium citrate, and 4 parts of sodium chloride in a beaker, add 80 parts of water and 12 parts of ethanol, stir to dissolve;

[0047] (2) Put the above solution in a constant temperature oil bath at 60°C for complexation reaction, and slowly precipitate sodium chloride through solvent volatilization method to obtain a gel-state substance coated with sodium chloride;

[0048] (3) Place the above-mentioned beaker containing the gel-state substance in an oven at 100 °C to promote the further cross-linking reaction of citrate and nickel ions, and the decomposition of part of citrate to obtain a fluffy solid powder material;

[0049] (4) Put the above solid powder material in a 300 °C atmosphere tube furnace, and perform high-temperature annealing trea...

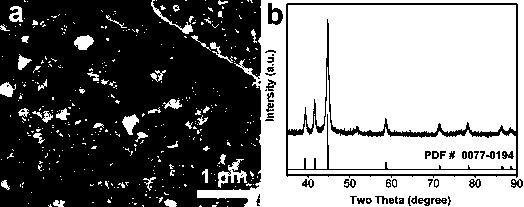

Embodiment 3

[0053] This embodiment provides a method for preparing a porous nickel carbide material, and the preparation steps are as follows:

[0054] (1) Put 1 part of nickel nitrate, 1 part of nickel chloride, 1 part of nickel acetate, 0.5 part of citric acid, 0.5 part of sodium citrate, 0.5 part of ammonium citrate, 0.5 part of potassium citrate, and 8 parts of sodium chloride in In the beaker, add 79 parts of water and 12 parts of ethanol, stir to dissolve;

[0055] (2) Put the above solution in a constant temperature oil bath at 80°C for complexation reaction, and slowly precipitate sodium chloride through solvent evaporation method to obtain a gel-state substance coated with sodium chloride;

[0056] (3) Place the above-mentioned beaker containing the gel-state substance in an oven at 120 °C to promote the further cross-linking reaction of citrate and nickel ions, and the decomposition of part of citrate to obtain a fluffy solid powder material;

[0057] (4) Put the above solid po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com