A kind of sealant processing technology

A processing technology and sealant technology, applied in the field of sealant processing technology, can solve problems such as easy blockage of feeding materials, and achieve the effects of improving efficiency, uniform collision, and aggravated shaking degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

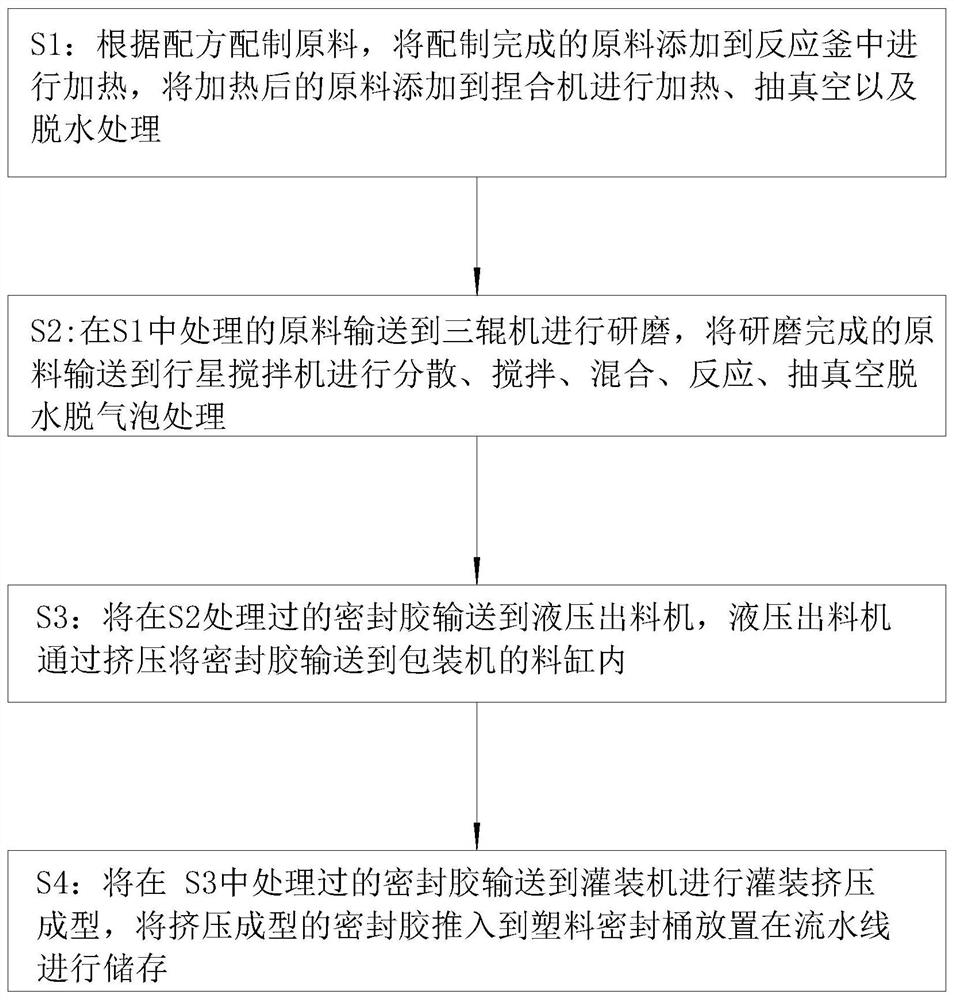

Method used

Image

Examples

Embodiment approach

[0035] As an embodiment of the present invention, the metal pipe 22 is provided with a funnel-shaped pipe 24, the two sides of the funnel-shaped pipe 24 are fixedly connected to the wall of the metal pipe 22 by springs, and the upper surface of the extruded pipe 32 is set There is an elastic rod 33, the bottom end of the elastic rod 33 is provided with a limit block 34, the bottom end of the elastic rod 33 passes through the extruding pipe 32, and the bottom end of the elastic rod 33 is arc-shaped; the extruding pipe 32 is provided with a push rod 35, which is connected to the cylinder 31; when the sealant flows to the extrusion channel 32 through the feed port 2, the hose 21 and the metal pipe 22, the cylinder 31 starts the unbooking push rod 35 Contact with the sealant and squeeze the sealant; the back and forth movement of the push rod 35 will contact the elastic rod 33 arranged above the extrusion channel 32, the bottom of the elastic rod 33 is set in an arc shape, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com