Preparation method of copper cerium catalyst with high dispersion of active species

A catalyst and highly dispersed technology, applied in the field of chemical materials, can solve the problems of highly dispersed active species and easy high-temperature agglomeration, and achieve the effects of orderly pores, large specific surface area, and reduced preparation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

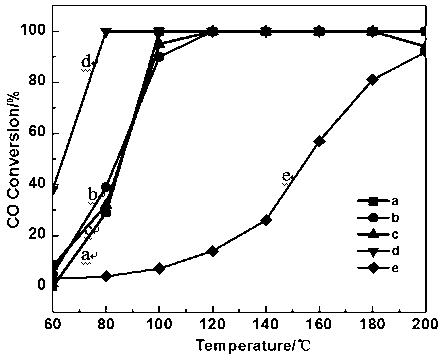

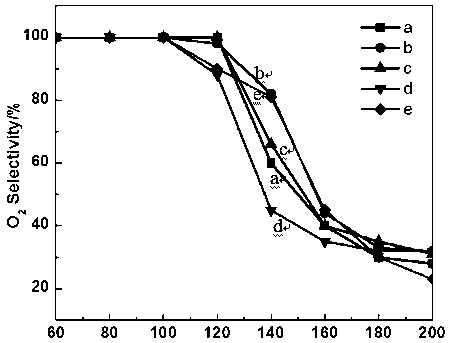

[0024] Example 1: Using Cu-MOF as a precursor to support cerium ions

[0025] Weigh 0.875 g of Cu(NO 3 ) 2 •6H 2 O was added to 12 ml of deionized water, and stirred to obtain solution A; 0.42 g of tricarboxylic acid organic ligand was dissolved in 12 ml of ethanol, and stirred to obtain solution B. Mix solution A and solution B, stir at room temperature for 30 min, place in a 40 ml polytetrafluoroethylene stainless steel reactor lining, keep the temperature in an oven at 120°C for 12 h, cool naturally to room temperature, take out the product, and filter After washing several times with ethanol and distilled water, blue powdery crystal Cu-MOF was obtained. 1.0 g Cu-MOF was impregnated into 7.0 g Ce(NO 3 ) 3 •6H 2 O solution, stood at room temperature for 24 h, and dried overnight at 100 °C. Finally, the copper-cerium catalyst a with a copper content of 5% was obtained by calcination at 800 °C for 6 h in a muffle furnace. By changing the amount of Cu-MOF to 0.4g and 2....

Embodiment 2

[0026] Example 2: Using Ce-MOF as a precursor to support copper ions

[0027] Weigh 0.05 g of Ce(NO 3 ) 3 •6H 2 O was added to 1 ml deionized water and stirred to obtain solution A; 0.105 g of 1,3,5-H 3 The BTC ligand was dissolved in water-ethanol solution (40 mL, v / v=1:1), and stirred to obtain solution B. Solution A and solution B were mixed, stirred at room temperature for 30 min, and then placed in a beaker. The solid was filtered, washed with ethanol and distilled water several times, and dried in air at room temperature to obtain the white product Ce-MOF. 1.0 g of Ce-MOF was impregnated with 0.23 g Cu(NO 3 ) 2 •6H 2 O aqueous solution, after standing at room temperature for 24 h, dried at 120 °C overnight. Finally, the obtained copper-cerium catalyst b was calcined in a muffle furnace at ℃ for 6 h.

Embodiment 3

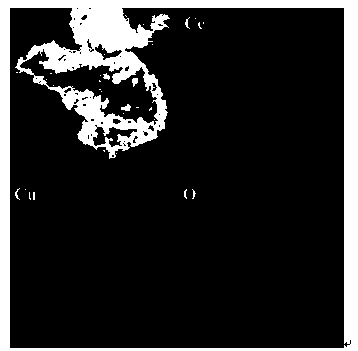

[0028] Example 3: Using CuCe-MOF as a precursor

[0029] Weigh 0.13 g of CuCl 2 • 2H 2 O and 0.0745 g of CeCl 3 •7H 2 O was added to 5 ml of deionized water and stirred to obtain a light green solution A; 0.2 g of methylenediacetic acid ligand was dissolved in 5 ml of deionized water, and the pH was adjusted to neutral with ammonia water to obtain a colorless and transparent solution B. Mix solution A and solution B to obtain a blue solution, adjust the pH to 5-6 with ammonia water, stir at room temperature for 30 min, place in an oven at 60 °C for 48 h, cool to room temperature naturally, take out the product, filter and wash with ethanol Washed several times with distilled water to obtain blue crystal CuCe-MOF. Finally, the blue crystal was calcined in a muffle furnace at 400 °C for 6 h to obtain copper-cerium catalyst c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com