Titanium-niobium-zirconium alloy dental implant with high strength, low elasticity modulus and no toxicity

A low-modulus, dental implant technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

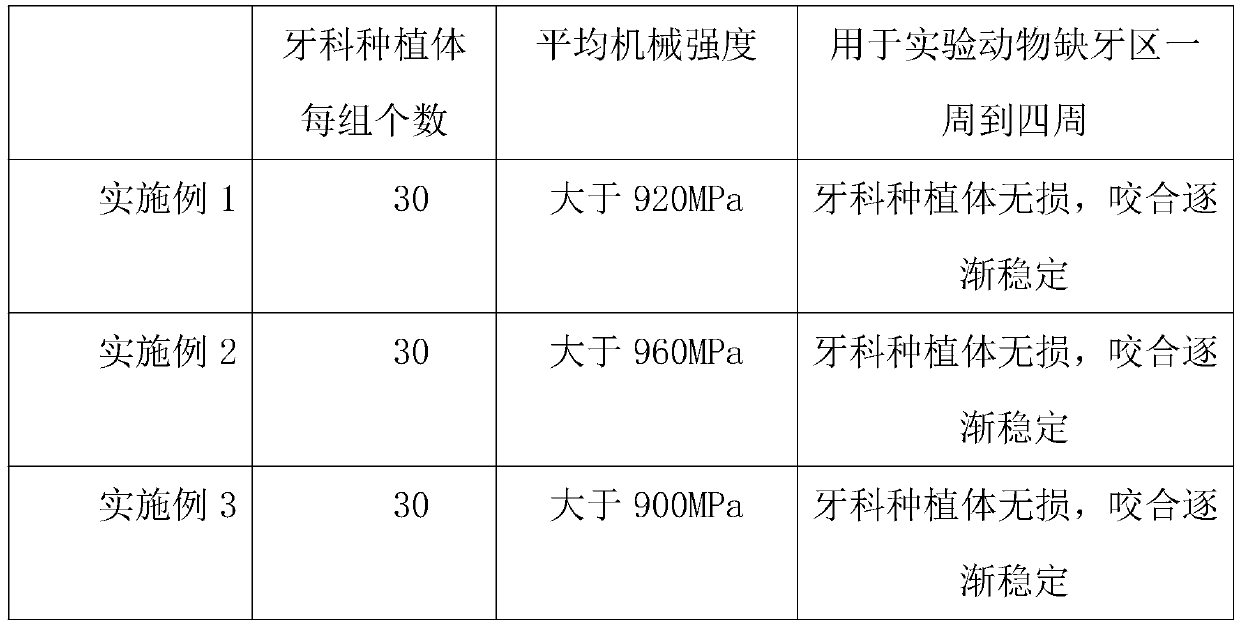

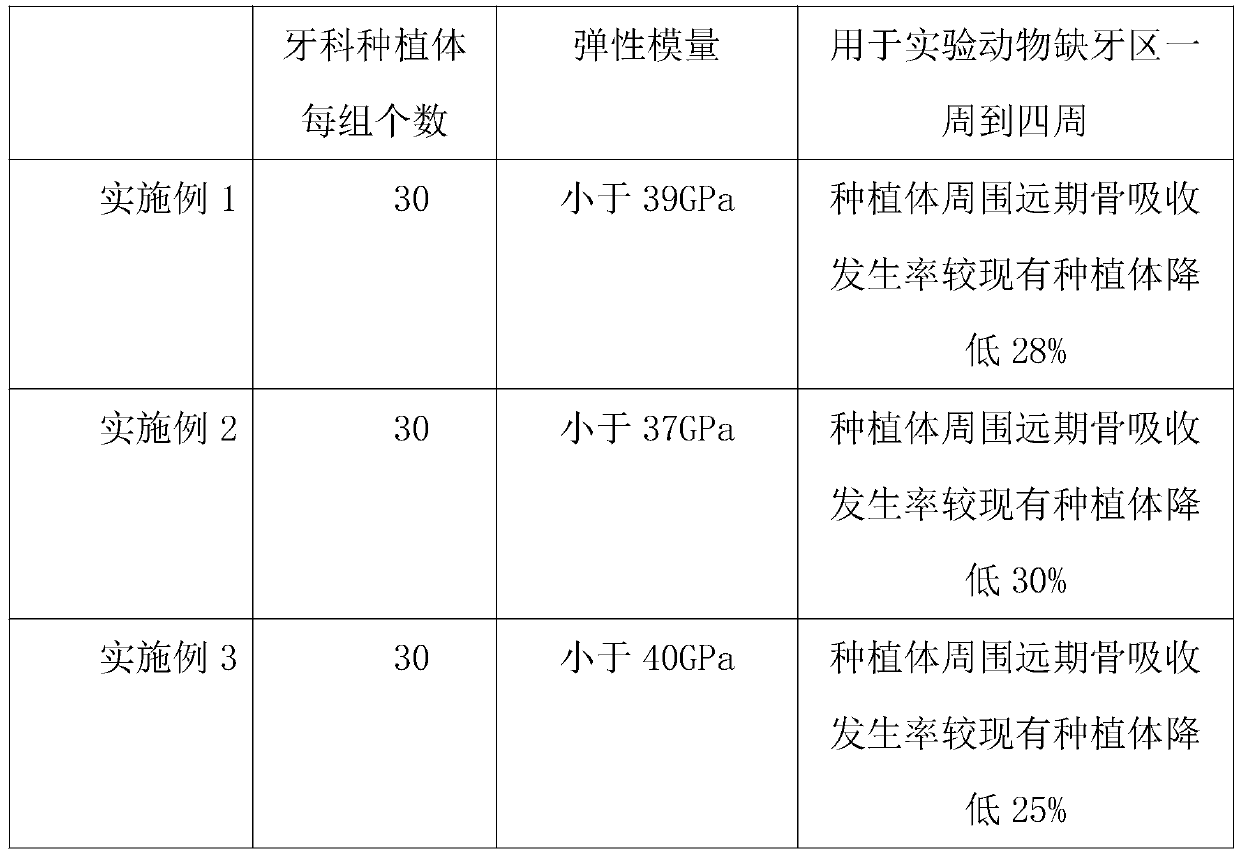

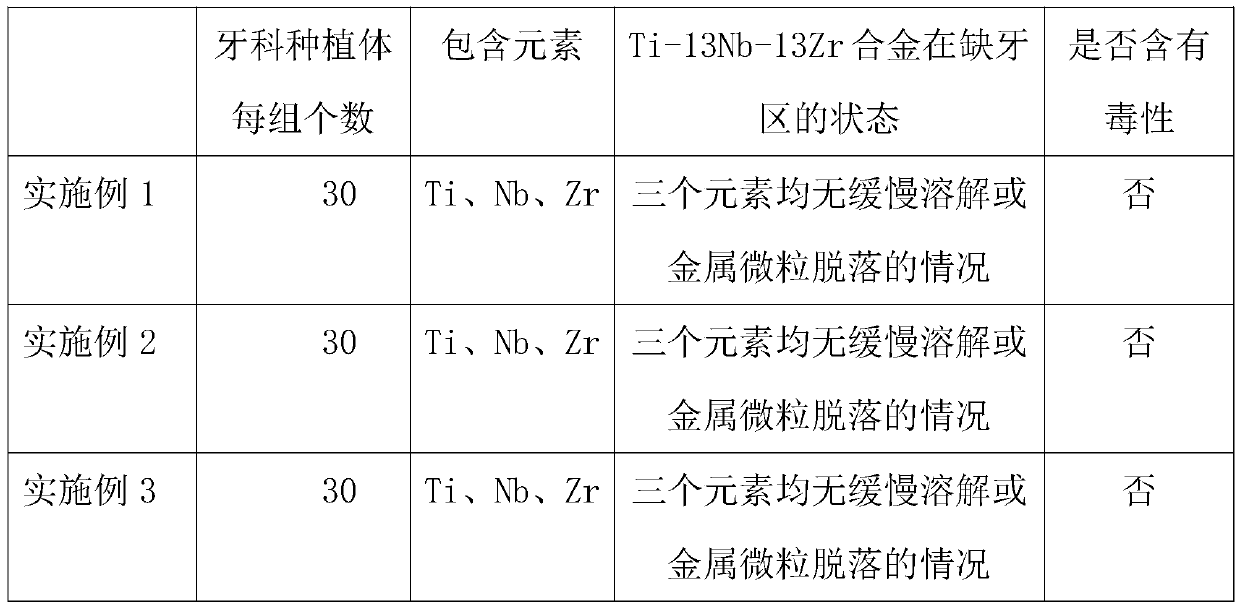

Examples

Embodiment 1

[0022] The invention provides a high-strength, low elastic modulus, non-toxic titanium-niobium-zirconium alloy dental implant, wherein the main material used is: Ti-13Nb-13Zr alloy, and the grade of the Ti-13Nb-13Zr alloy is TC26 ;

[0023] The present invention also provides a method for preparing a high-strength, low elastic modulus, non-toxic titanium-niobium-zirconium alloy dental implant. The specific processing steps are as follows:

[0024] Step S1, powder grinding, using a plasma laser to rotate the prepared Ti-13Nb-13Zr alloy at high speed under the protection of argon into a spherical powder with a diameter of 10 microns, and vacuum packaging for later use;

[0025] Step S2, use the Ti-13Nb-13Zr alloy powder ground in step S1 to use the selective laser melting process, the laser power of the selective laser melting is 100W, the laser speed is 400mm / s, and the thickness of each layer of powder is 20μm, according to the computer The preset shape of the implant is proc...

Embodiment 2

[0027] The invention provides a high-strength, low elastic modulus, non-toxic titanium-niobium-zirconium alloy dental implant, wherein the main material used is: Ti-13Nb-13Zr alloy, and the grade of the Ti-13Nb-13Zr alloy is TC26 ;

[0028] The present invention also provides a method for preparing a high-strength, low elastic modulus, non-toxic titanium-niobium-zirconium alloy dental implant. The specific processing steps are as follows:

[0029] Step S1, powder grinding, using a plasma laser to rotate the prepared Ti-13Nb-13Zr alloy at high speed under the protection of argon into a spherical powder with a diameter of 25 microns, and vacuum pack it for later use;

[0030] Step S2, use the Ti-13Nb-13Zr alloy powder ground in step S1 to use the selective laser melting process, the laser power of the selective laser melting is 300W, the laser speed is 1200mm / s, and the thickness of each layer of powder coating is 25μm, according to the computer The preset shape of the implant ...

Embodiment 3

[0032] The invention provides a high-strength, low elastic modulus, non-toxic titanium-niobium-zirconium alloy dental implant, wherein the main material used is: Ti-13Nb-13Zr alloy, and the grade of the Ti-13Nb-13Zr alloy is TC26 ;

[0033] The present invention also provides a method for preparing a high-strength, low elastic modulus, non-toxic titanium-niobium-zirconium alloy dental implant. The specific processing steps are as follows:

[0034] Step S1, powder grinding, using a plasma laser to rotate the prepared Ti-13Nb-13Zr alloy at high speed under the protection of argon into a spherical powder with a diameter of 50 microns, and vacuum packaging for later use;

[0035] Step S2, use the Ti-13Nb-13Zr alloy powder ground in step S1 to use the selective laser melting process, the laser power of the selective laser melting is 500W, the laser speed is 2000mm / s, and the thickness of each layer of powder is 30μm, according to the computer The preset shape of the implant is pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mechanical strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com