All-dry micro-bundle optical cable

An all-dry, optical cable technology, applied in the field of optical cables, which can solve the problems of large outer diameter, peeling or migration of the coloring layer, leakage of the sheath, etc., and achieves the effects of stable performance, efficient and fast construction, and increased space ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

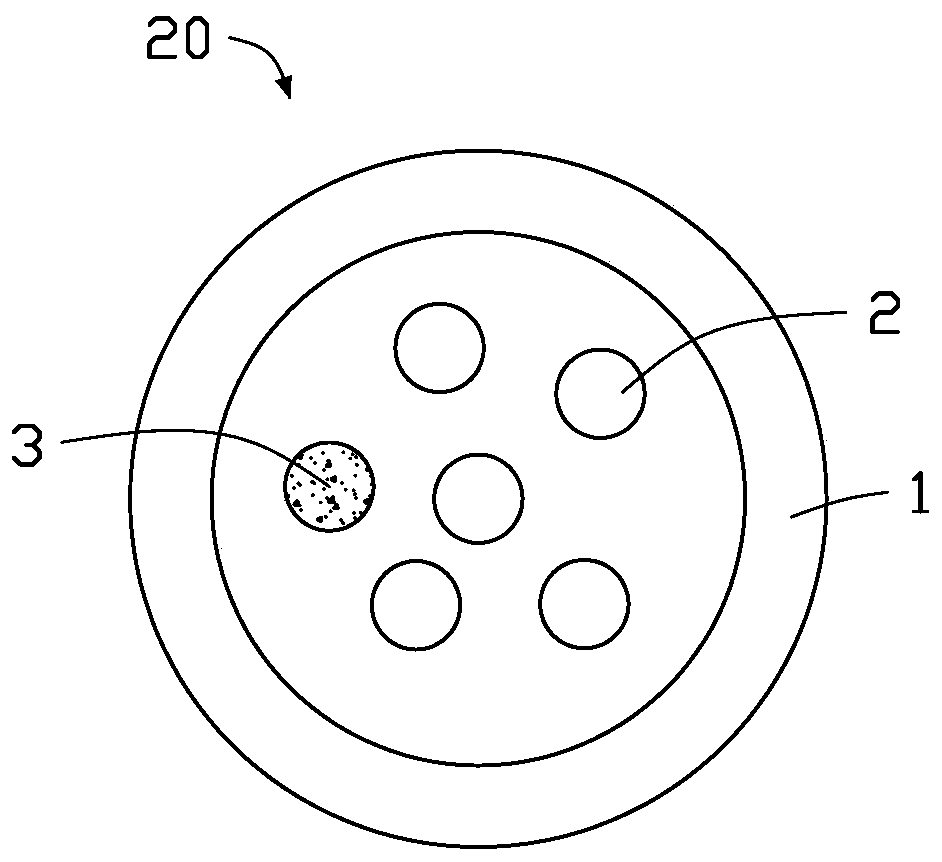

[0051] In this example, the number of optical fiber cores of a kind of easy-to-peel dry-type optical fiber microtube 20 is 6 cores, as figure 1 shown.

[0052] There are 6 optical fibers in each optical fiber microtube 20. The colors of the optical fibers 2 are blue, orange, green, brown, gray, and white. The optical fibers are G.652D optical fibers. Adopt SZ twist.

[0053] Each optical fiber microtube 20 contains a 300D water-blocking yarn 3, the water-blocking yarn 3 has a linear density of 30,000m / kg, and performance selection requirements: tensile strength ≥ 12N, elongation at break ≥ 12%, thermal shrinkage ≤ 3.5%, expansion rate ≥ 25ml / g / min, expansion rate ≥ 30ml / g, water content ≤ 8%. In this case, it is a water-absorbing fiber containing acrylate, and its matrix is mainly polyester or nylon.

[0054] The wall thickness of the microtube sheath 1 is 0.1mm, and the material of the microtube sheath 1 is a mixture of linear low-density polyethylene, carbon black and s...

Embodiment 2

[0057] In this example, the number of optical fiber cores of an easy-stripping dry-type optical fiber microtube 20 is 12.

[0058] There are 12 optical fibers 2 in each microtube 20. The colors of the optical fibers 2 are blue, orange, green, brown, gray, white, red, black, yellow, purple, pink, and turquoise. The optical fibers are G.657A2 optical fibers. The diameter of the coating is 200 μm±10 μm, and the optical fiber in the microtube 20 adopts SZ stranding.

[0059] Each microtube 20 contains one piece of 300D water-blocking yarn 3, the linear density of water-blocking yarn 3 is 30,000m / kg, and the performance selection requirements: tensile strength ≥ 12N, elongation at break ≥ 12%, thermal shrinkage ≤ 3.5 %, expansion rate ≥ 25ml / g / min, expansion rate ≥ 30ml / g, water content ≤ 8%. In this example, it is a water-absorbing fiber cured with polyacrylic acid and acrylate, and its matrix is mainly polyester or nylon.

[0060] The wall thickness of the microtube sheath 1 ...

Embodiment 3

[0063] An easy-stripping dry-type optical fiber microtube 20, the number of optical fiber cores is 12.

[0064] There are 12 optical fibers 2 in each microtube 20. The colors of the optical fibers 2 are blue, orange, green, brown, gray, white, red, black, yellow, purple, pink, and turquoise. The optical fibers 2 are G.657A2 optical fibers. The diameter of the coating is 250 μm ± 10 μm, and the optical fiber 2 adopts SZ stranding in the microtube sheath 1 .

[0065] Each microtube 20 contains a 600D water-blocking yarn 3, the density of the water-blocking yarn 3 is 15,000m / kg, and the performance selection requirements: tensile strength ≥ 20N, elongation at break ≥ 12%, thermal shrinkage ≤ 3.5% , expansion rate ≥ 30ml / g / min, expansion rate ≥ 40ml / g, water content ≤ 8%. In this example, it is a water-absorbing fiber containing acrylic acid graft copolymer, and its matrix is mainly polyester or nylon.

[0066] The wall thickness of the microtube sheath 1 is 0.2mm, and the mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com