Ultrasonic atomizer and water shortage detection device

An ultrasonic atomizer and detection device technology, applied in the field of electronics, can solve the problems of short life, easy oxidation, easy failure, etc., and achieve the effect of long life, not easy to misjudgment and oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The implementation of the present invention will be described in detail below with reference to the accompanying drawings and embodiments, so as to fully understand how the present invention applies technical means to solve technical problems and achieve the realization process of technical effects and implement them accordingly. It should be noted that, as long as there is no conflict, each embodiment of the present invention and each feature in each embodiment can be combined with each other, and the technical solutions formed are all within the protection scope of the present invention.

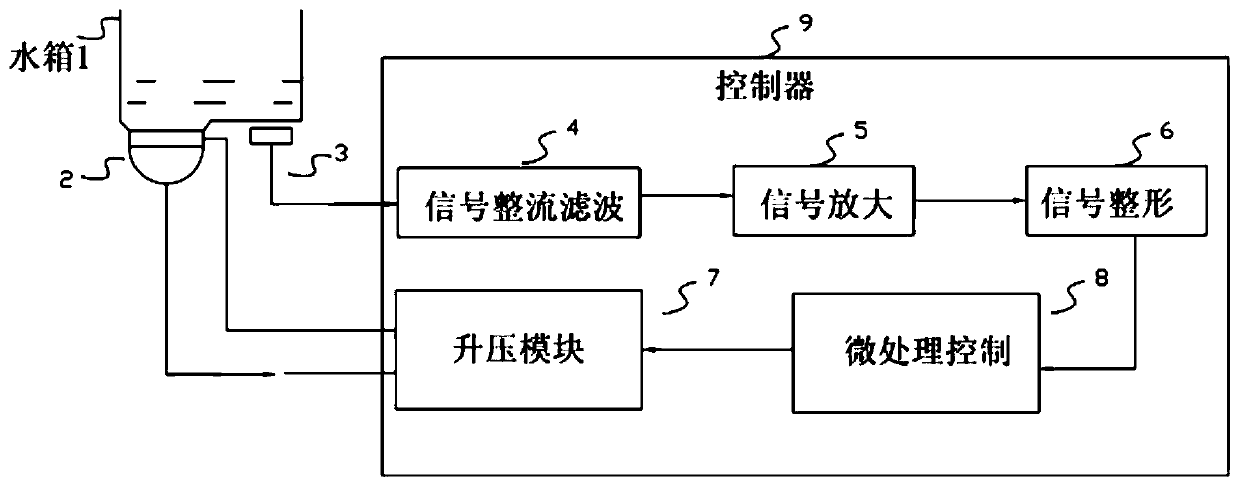

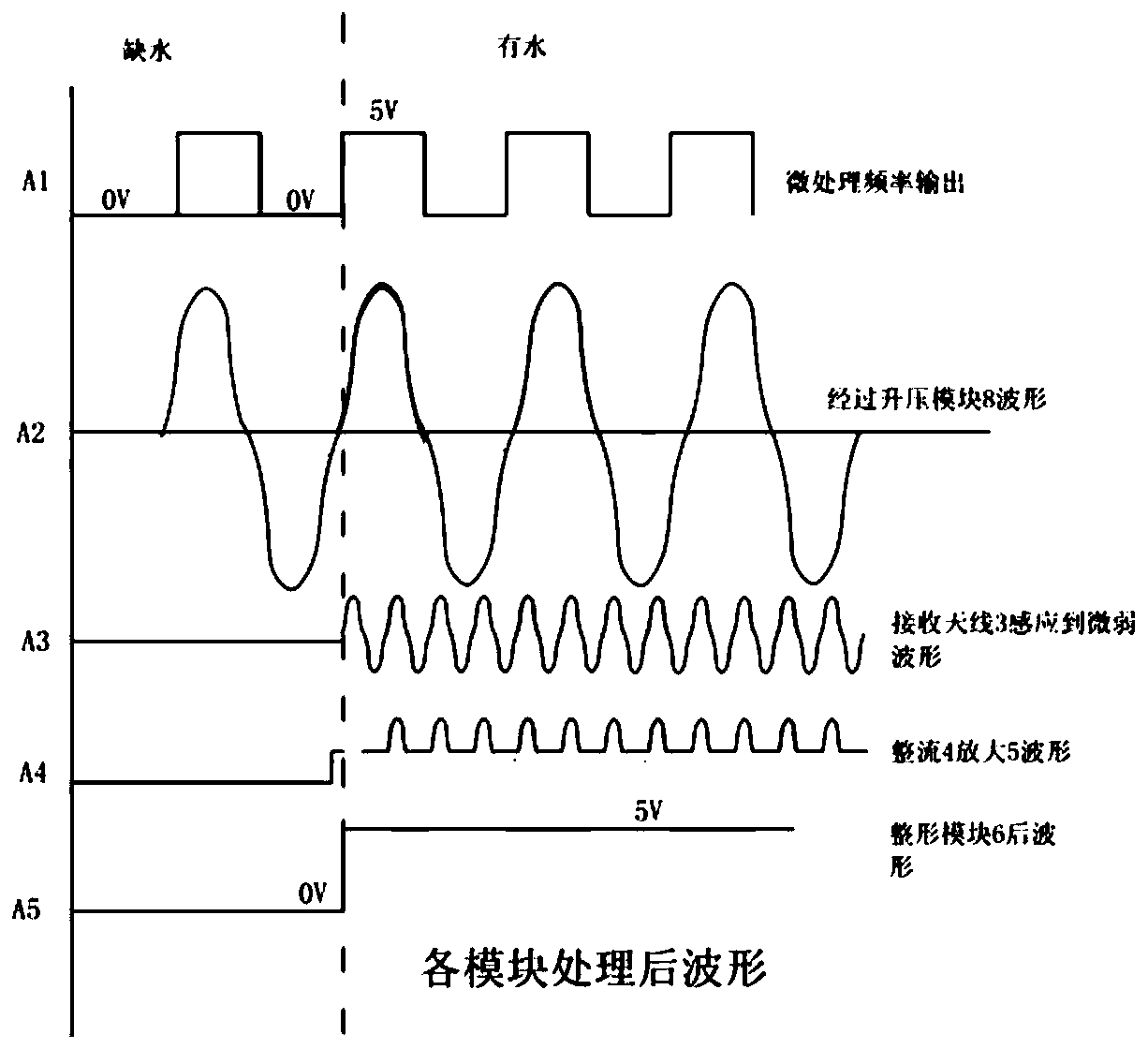

[0027] Such as Figure 1-4 As shown, an ultrasonic atomizer includes: a water tank (1), an atomizing sheet (2), an induction antenna (3) and a water shortage detection device (9), wherein the induction antenna (3) contacts the bottom shell of the water tank, Used to sense whether there is water, the atomizer (2) is installed at the bottom of the water tank; the water shortage detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com