Polymer composite PE water supply pipe

A water supply pipe and polymer technology, which is applied in the field of connecting pipes, can solve problems such as harming health and reducing hydrophobic efficiency, and achieve the effects of avoiding scale, increasing the range of motion, and avoiding a large amount of accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

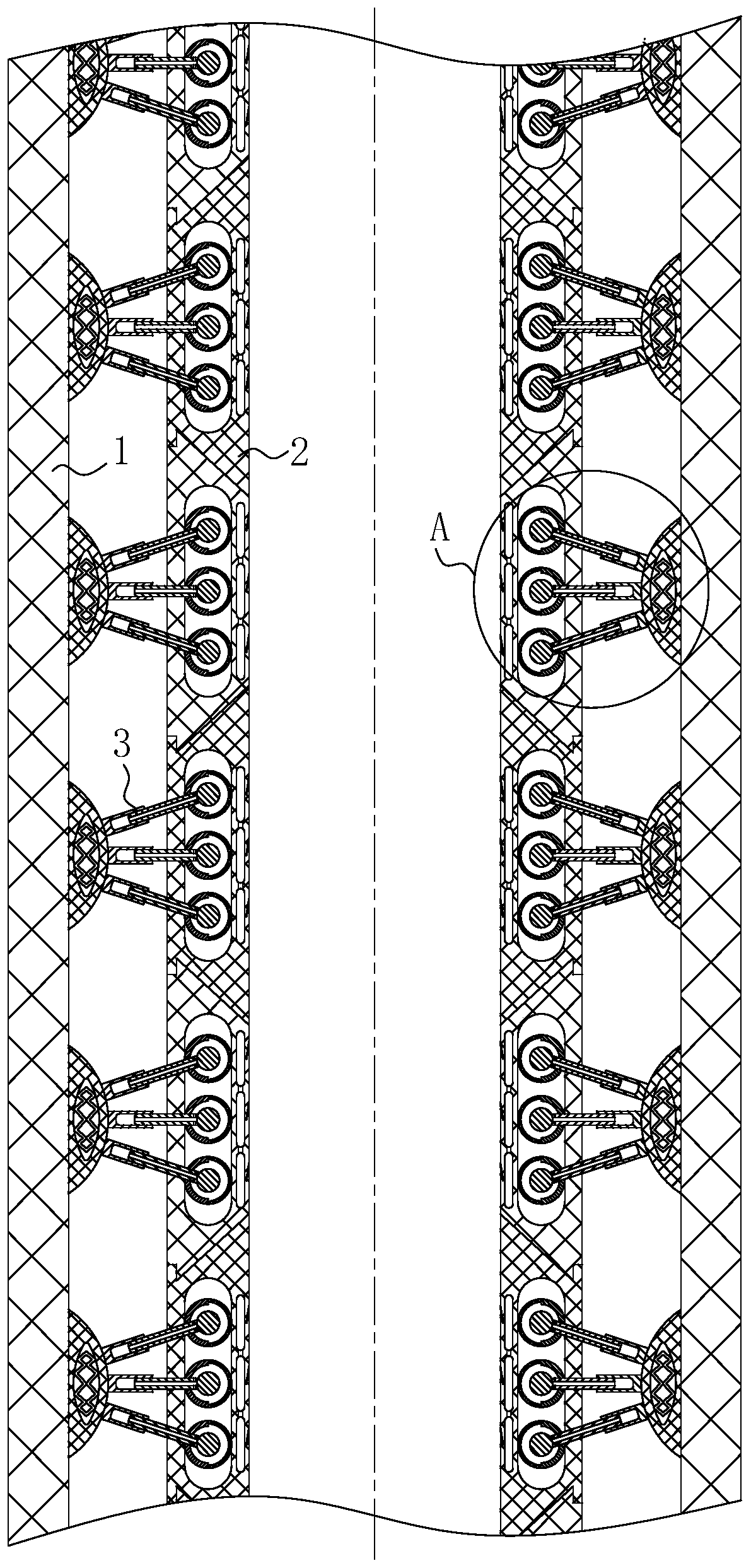

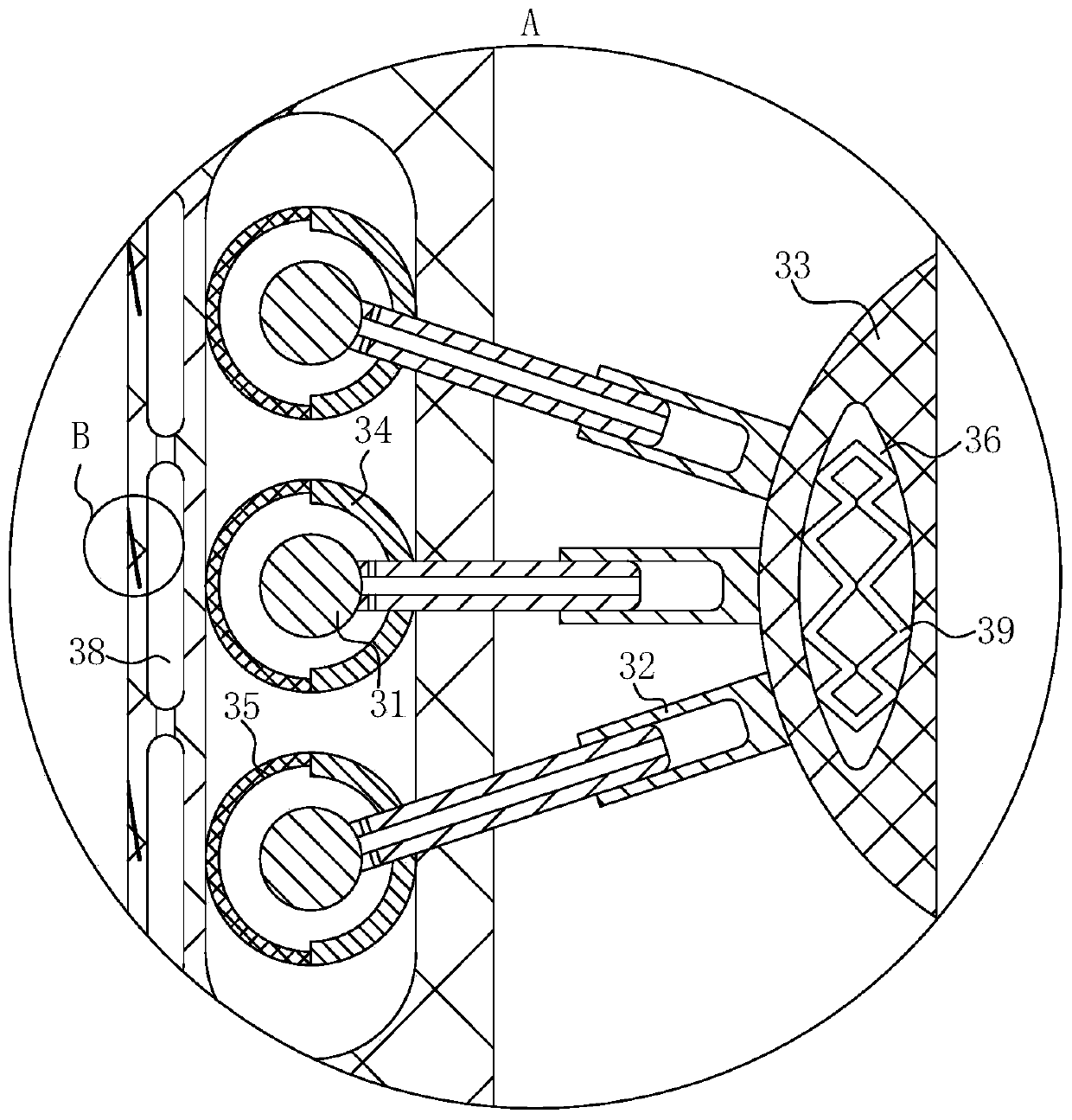

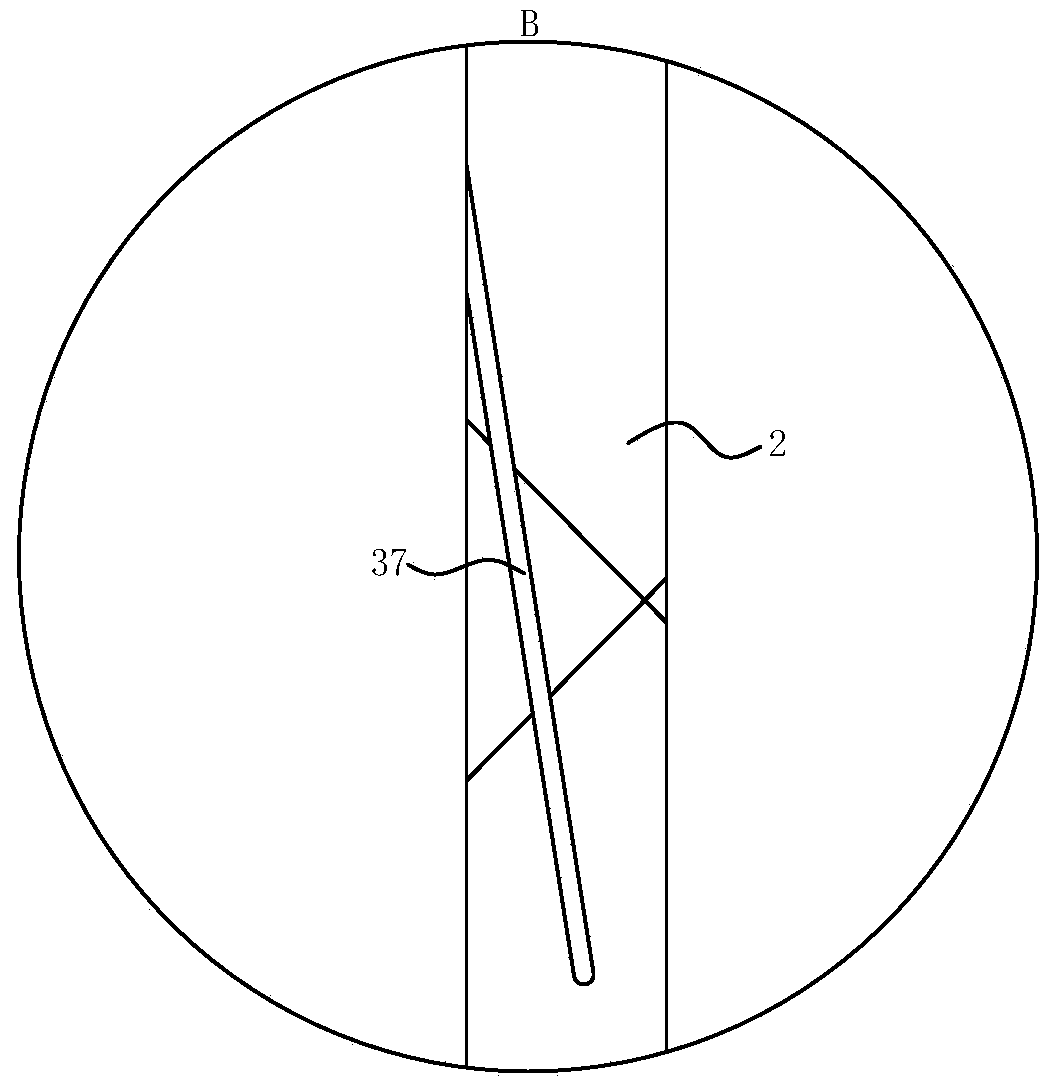

[0018] use Figure 1-Figure 3 A polymer composite PE water supply pipe according to an embodiment of the present invention is described as follows.

[0019] Such as Figure 1-Figure 3 As shown, a polymer composite PE water supply pipe according to the present invention includes an outer pipe 1, an inner pipe 2 and an extruding mechanism 3; a certain gap is provided between the inner pipe 2 and the outer pipe 1, and the inner pipe 2 It is set to be segmented and fixedly connected, and the inner tube 2 is provided with an extrusion mechanism 3; the extrusion mechanism 3 includes an extrusion ring 31, an elastic support rod 32 and a mounting ring 33; the mounting ring 33 is evenly and fixedly installed on the outer tube 1 On the inner wall of the mounting ring 33, the inner surface of the mounting ring 33 is uniformly fixed with an elastic support rod 32 around the circumference; the inner end of the elastic support rod 32 is fixedly connected with an extrusion ring 31; the extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com