Anti-loosening and anti-vibration structure of hydraulic pipeline pipe clamp at vibration part in hydraulic system

A technology of vibration parts and hydraulic pipelines, which is applied in the direction of pipeline supports, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problems of hydraulic pipeline vibration intensification, hydraulic pipeline joint loosening, pipeline leakage, etc., to eliminate potential safety hazards, Ensure reliable fastening and avoid loose effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

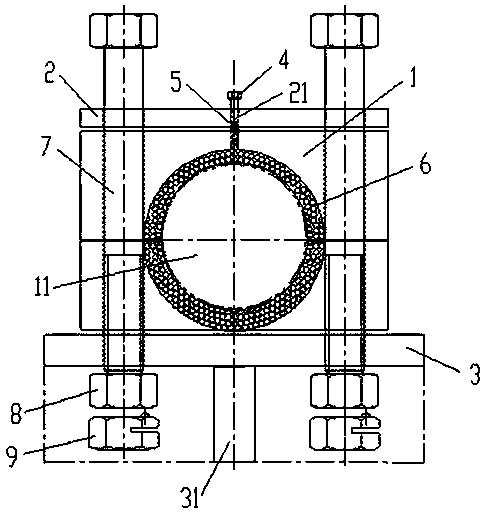

[0010] Example figure 1 As shown, the anti-loosening and anti-vibration structure of the hydraulic pipeline pipe clip in the hydraulic system of the present invention includes a pipe clip 1, an upper cover plate 2, a bottom plate 3, a compression bolt 4, a compression spring 5, some steel balls 6, two long Bolts 7 and two lock nuts 8, the pipe clip 1 is two semicircular hoops with a rectangular cross-section, the inner ring of the pipe clip 1 is provided with a circular long groove along the circumferential direction, and the upper cover plate 2 and the bottom plate 3 are respectively arranged on the top surface and the bottom surface of the pipe clamp 1, the two long bolts 7 penetrate into the upper cover plate 2, the tube clamp 1 and the bottom plate 2 sides in turn, and the two lock nuts 8 Screw in the bottom ends of the two long bolts 7 and fasten the upper cover plate 2, the pipe clamp 1 and the bottom plate 3, the middle part of the upper cover plate 2 has a screw hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com