Elastic transition section cylindrical foundation structure and construction method thereof

A cylindrical foundation and transition section technology, which is applied in infrastructure engineering, wind power generation, construction, etc., can solve problems such as unreasonable load transfer, complicated construction and installation, and achieve a clear structural stress system, short construction period, and reduced marine The effect of operational difficulty and risk of wind turbine damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

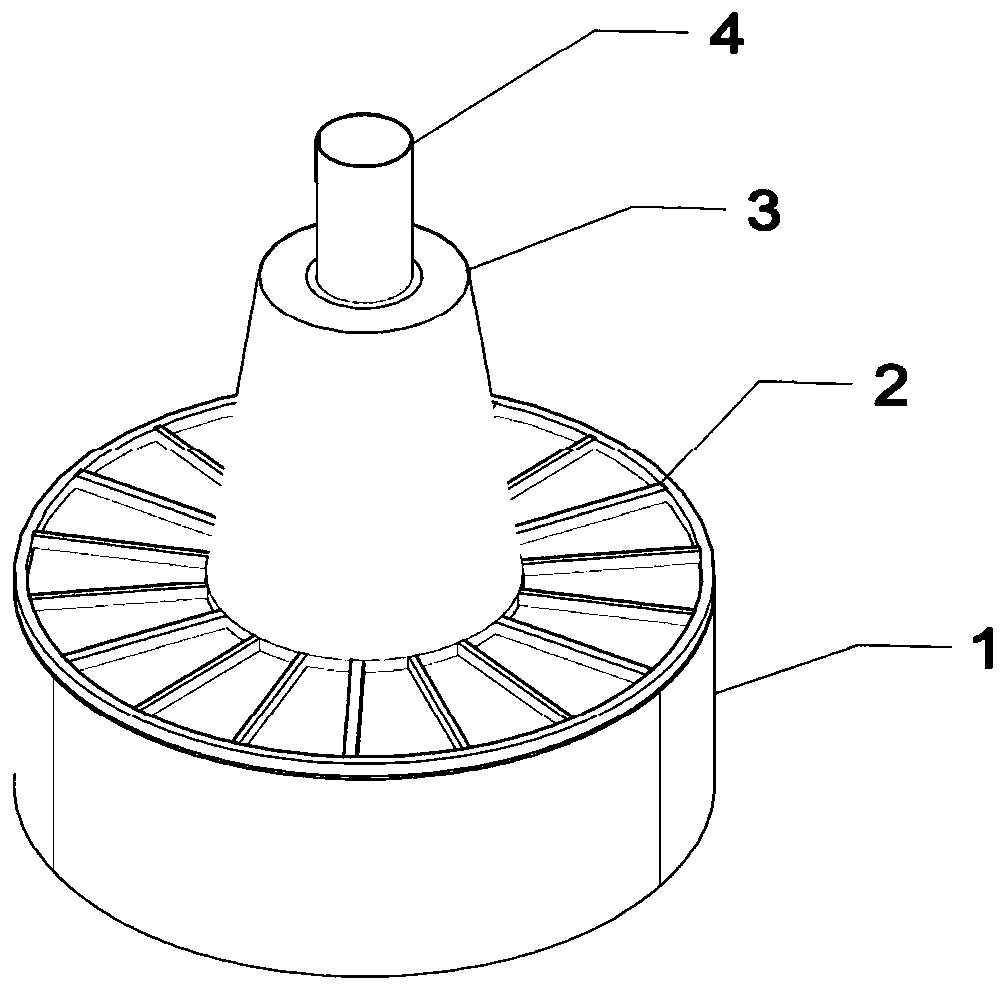

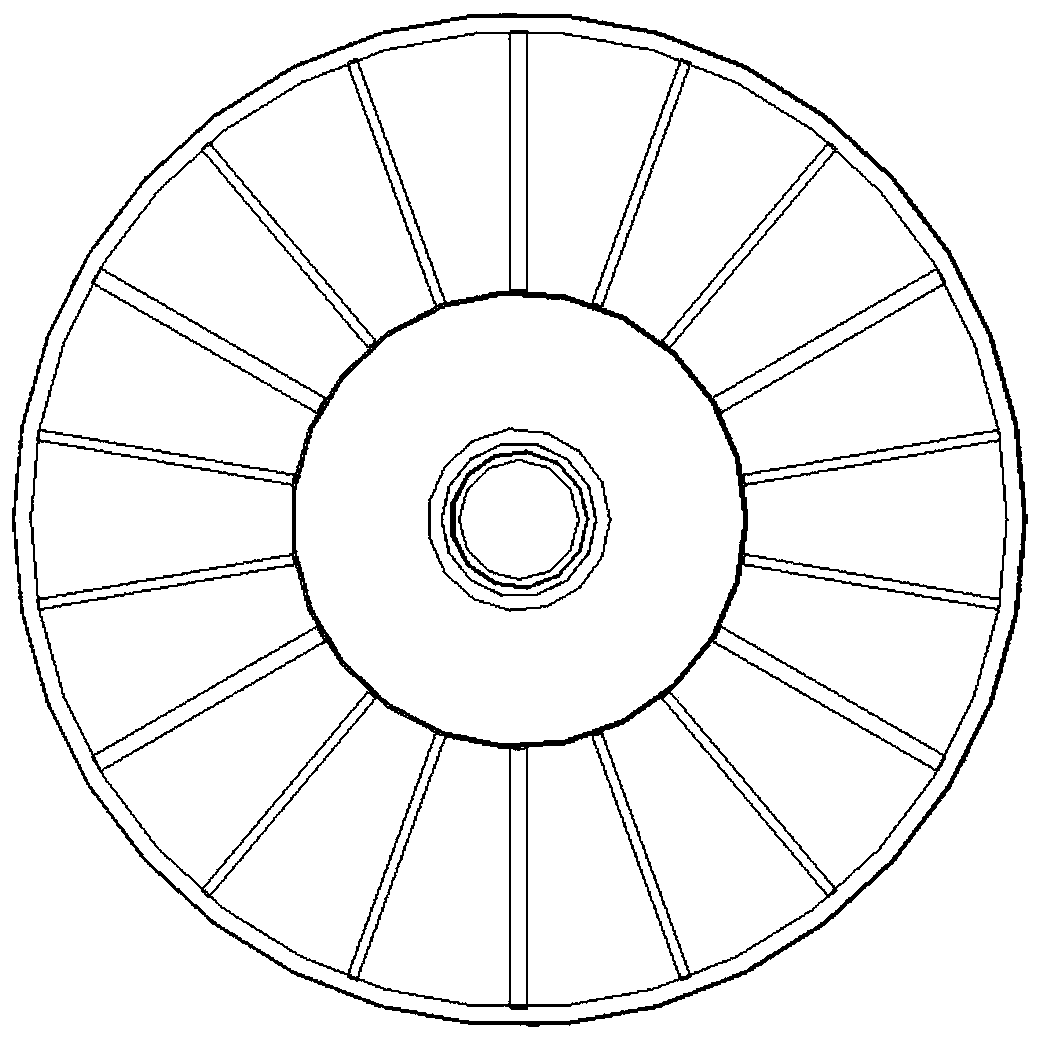

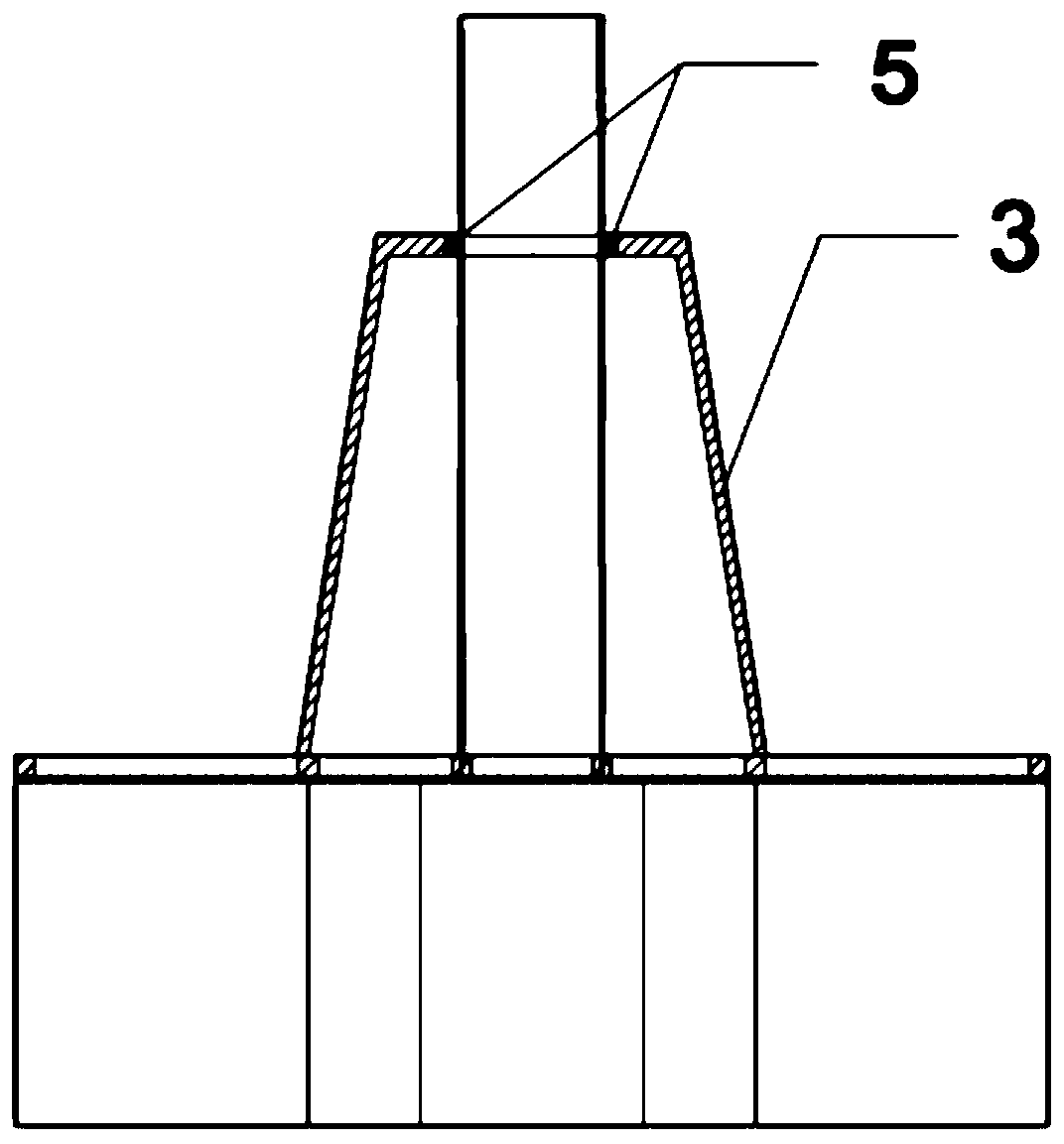

[0035] Such as Figure 1 to Figure 3 As shown, this embodiment discloses a cylindrical foundation structure in the elastic transition section, including a steel cylinder structure 1 with a compartment structure, a steel roof 2, a concrete slab 3, an outer ring beam 4, a middle ring beam 5, a first inner Ring beam 6 , second inner ring beam 7 , concrete main beam 8 , concrete secondary beam 9 , concrete transition section 10 , and steel tower tube 11 .

[0036] The steel cylinder structure 1 has a radius of 10-25m, a height of 5-15m, and a cylinder wall thickness of 10-50mm. The steel cylinder structure 1 is divided into a plurality of cabins by dividing panels, and the plurality of cabins include a middle cabin and a plurality of side tanks ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com