Water-soluble blocked polyurethane curing agent and preparation method and application thereof

A polyurethane curing agent, closed-type technology, applied in polyurea/polyurethane adhesives, polyurea/polyurethane coatings, adhesives, etc., can solve the problems of high product molecular weight, decreased effective functional group ratio of curing agent, low solid content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

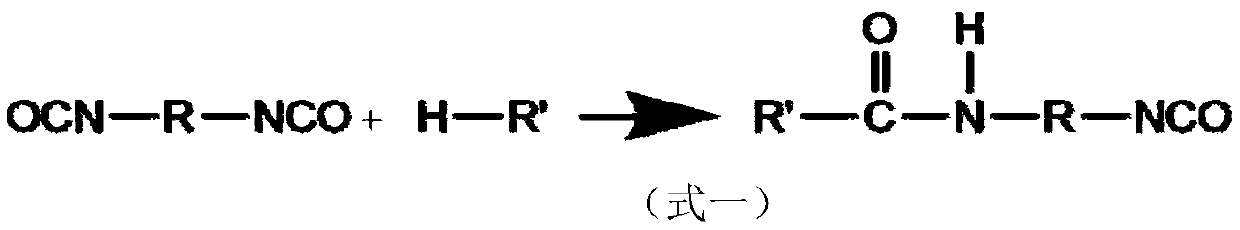

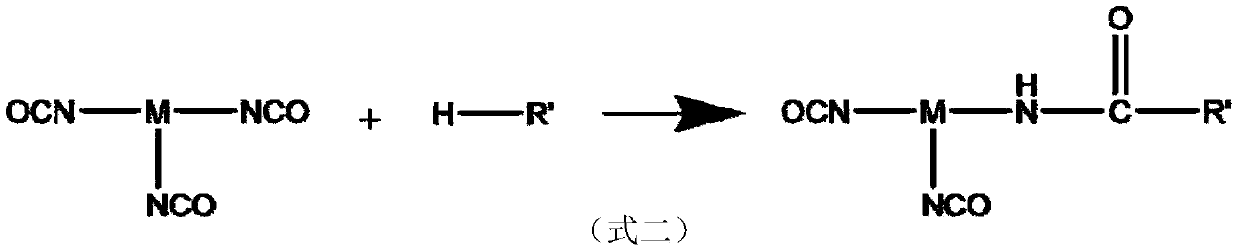

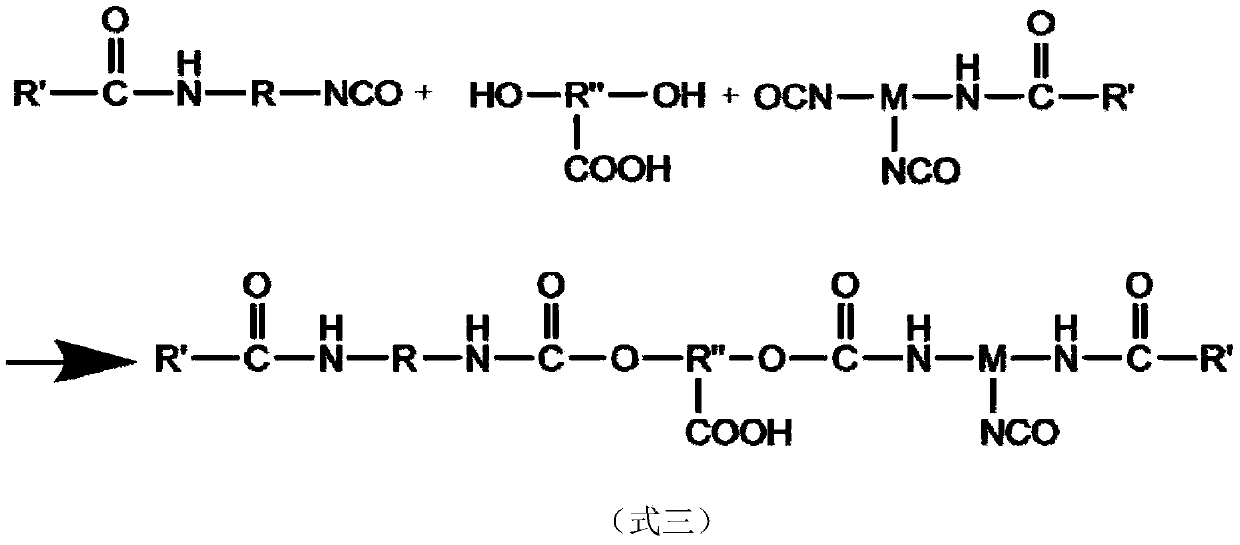

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Step 1: preparing a partial block of isocyanate;

[0066] In the prepolymerization kettle, add 100g IPDI and 50g acetone, add 35g methyl ethyl ketone oxime dropwise at room temperature, drop it in 1.5 hours, the temperature does not exceed 52 ° C, and obtain a partial closure of IPDI (component A).

[0067] Step 2: preparing partially blocked polyisocyanate prepolymers containing hydrophilic carboxyl groups;

[0068] Adopt process 1, the specific process is: in the reactor, add 250g acetone and 66.7g dimethylol butanoic acid, heat to 50 ℃ and dissolve completely, dropwise add 0.3g dibutyltin dilaurate catalyst (due to IPDI, HDI The reactivity of the trimer is low), and the component A is added dropwise, and the dropwise addition is completed in about 1 hour, during which the temperature is kept at 50±2°C. After the dropwise addition, keep it at 50°C for 1 hour, rise to below 60°C for 10 hours, then add 246.5g of HDI trimer (NCO% is 23.0%), add 0.3g of dibutyltin dilaur...

Embodiment 2

[0072] Step 1: preparing a partial block of isocyanate;

[0073] Add 100g of IPDI and 40g of acetone to prepolymerization kettle 1, raise the temperature to 50°C and add 35g of methyl ethyl ketone oxime dropwise for 1 hour, and the dropping temperature is 50-52°C to obtain component A.

[0074] In prepolymerization kettle two, add 328g HDI trimer (NCO% is 23.0%) and 50g acetone, add 51g methyl ethyl ketoxime dropwise at normal temperature, dropwise finish in 1 hour, dropwise temperature does not exceed 50 ℃, obtains component B.

[0075] Step 2: preparing partially blocked polyisocyanate prepolymers containing hydrophilic carboxyl groups;

[0076] Adopt process 1, the specific process is: in the reactor, add 250g acetone and 67g dimethylol propionic acid, heat to 50 ℃ and completely dissolve, dropwise add 0.3g stannous octoate catalyst, stir evenly, first add component A, The addition was completed in about 1 hour, during which the temperature was kept at 50±2°C, and reacted ...

Embodiment 3

[0080] Step 1: preparing a partial block of isocyanate;

[0081] In the reactor, add the prepolymer of 582gTDI and trimethylolpropane (solid content is 75%, NCO% is 13.0%), 100gMDI, 200g acetone, 80g propylene glycol methyl ether acetate, after mixing evenly, add under normal temperature 91 g of methyl ethyl ketoxime was added over 1.5 hours at a temperature not exceeding 50° C. to obtain a partially blocked isocyanate (component C).

[0082] Step 2: preparing partially blocked polyisocyanate prepolymers containing hydrophilic carboxyl groups;

[0083] Adopt process 2, the specific process is: raise the temperature in the reactor to 50°C, add 67g of dimethylolpropionic acid in 5 times, add it within 1 hour, keep it at 50±2°C for 1 hour after the addition, and then Raise the temperature to 60±2°C and react for 6 hours.

[0084] Step 3: preparing a water-soluble closed polyurethane curing agent;

[0085] Lower the temperature of the material in the reactor to 50°C, slowly add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com