Diffusion welding method for backplane and high-purity metal target

A diffusion welding and metal target technology, which is applied in welding equipment, metal processing equipment, non-electric welding equipment, etc., can solve difficult to meet process requirements, low recrystallization temperature of high-purity metals, and adverse effects of target electrical and thermal conductivity, etc. problems, to achieve the effect of easy industrialization and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a diffusion welding method for a backplane and a high-purity metal target, the backplane is a CuCr alloy backplane, the high-purity metal target is a copper target, and the method includes the following steps:

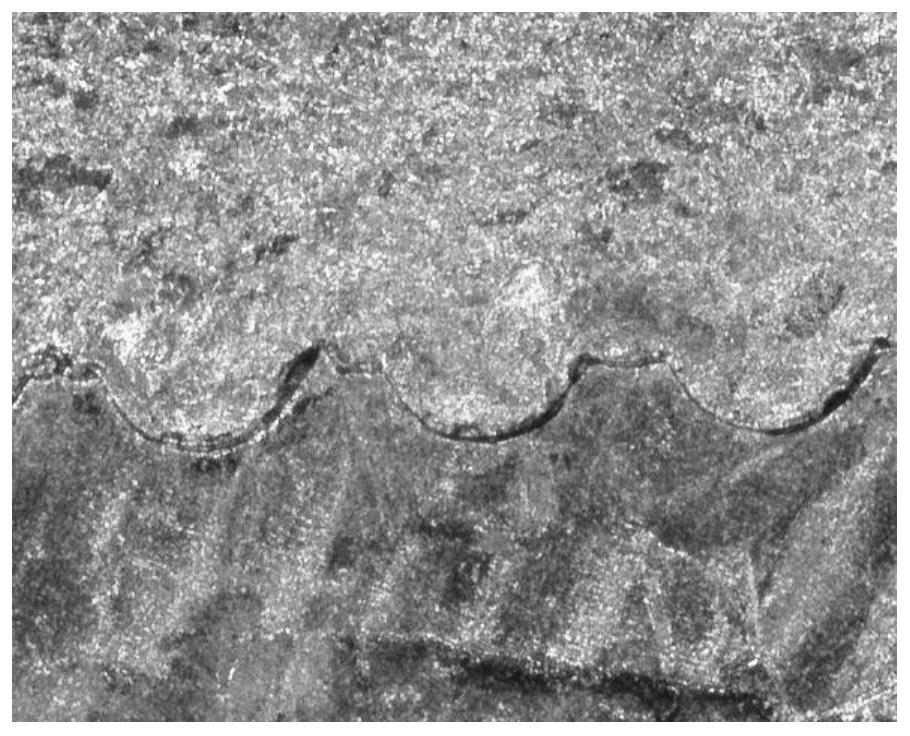

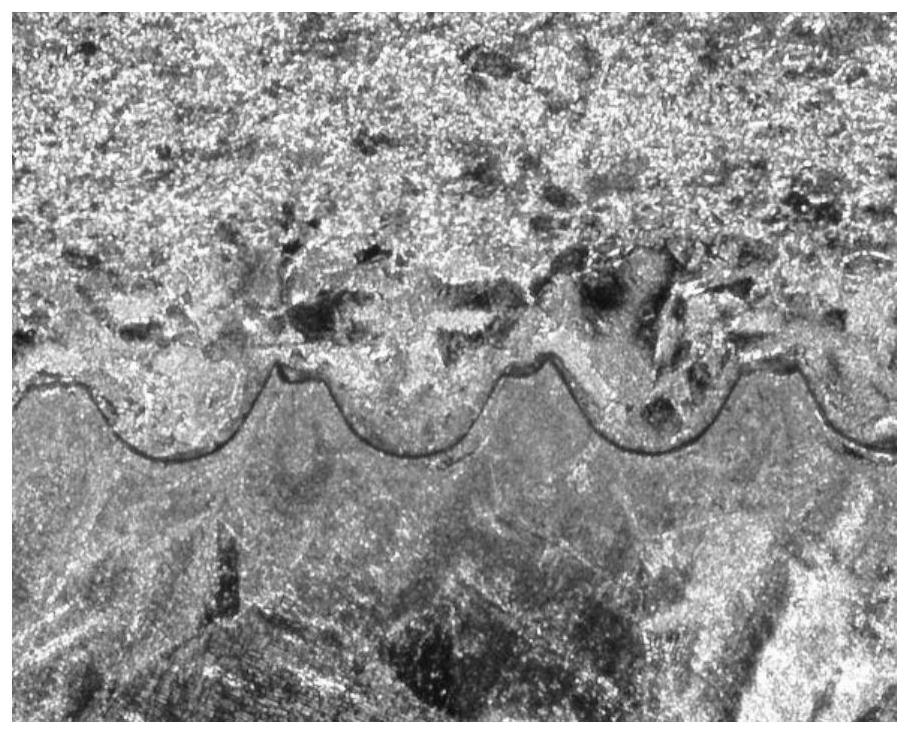

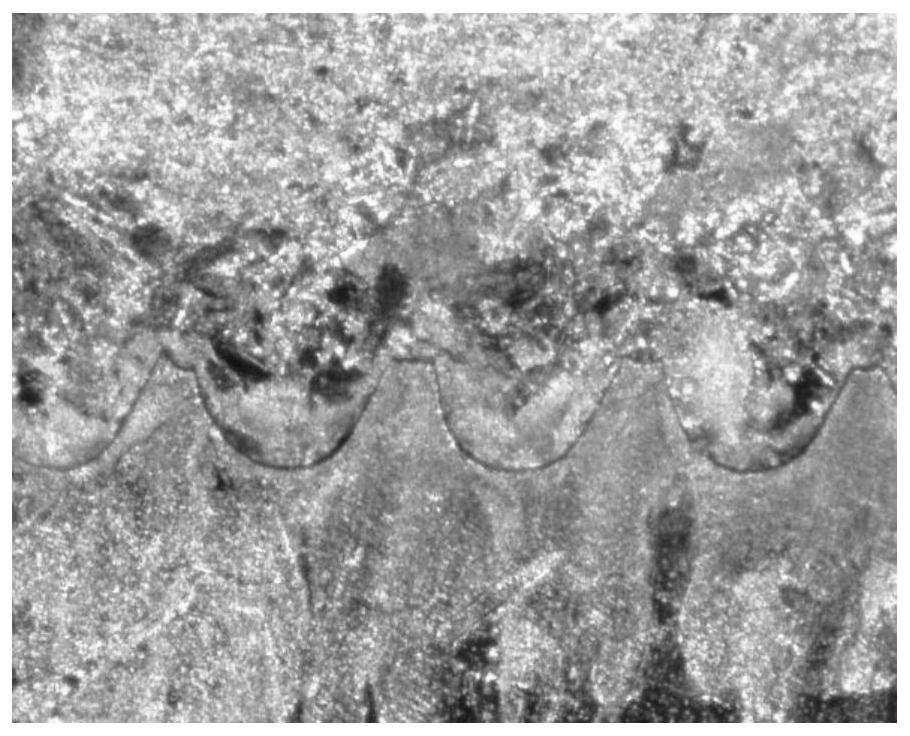

[0055] (1) Prepare the copper target material and the CuCr alloy back plate, and process threads on the welding surface of the CuCr alloy back plate;

[0056] (2) Combine the copper target material and the CuCr alloy back plate, and place the combined material in the metal sheath;

[0057] (3) Carry out degassing treatment to the metal sheath of packing composite material, then the metal sheath is sealed, and the vacuum degree of described degassing treatment is 1 * 10 -2 Pa, the temperature is 150°C, and the time is 3h;

[0058] (4) Place the sealed metal sheath in a cold isostatic press, boost the pressure to 250MPa, keep the pressure for 20min, and complete the cold isostatic pressing treatment after depressurization;

[0059] (5) C...

Embodiment 2

[0063] This embodiment provides a diffusion welding method for a backplane and a high-purity metal target, the backplane is a CuCr alloy backplane, the high-purity metal target is a copper target, and the method includes the following steps:

[0064] (1) Prepare the copper target material and the CuCr alloy back plate, and process threads on the welding surface of the CuCr alloy back plate;

[0065] (2) Combine the copper target material and the CuCr alloy back plate, and place the combined material in the metal sheath;

[0066] (3) Carry out degassing treatment to the metal sheath of packing composite material, then the metal sheath is sealed, and the vacuum degree of described degassing treatment is 1 * 10 -3 Pa, the temperature is 180°C, and the time is 2h;

[0067] (4) Place the sealed metal sheath in a cold isostatic press, increase the pressure to 240MPa, hold the pressure for 25min, and complete the cold isostatic pressing treatment after depressurization;

[0068] (5...

Embodiment 3

[0072] This embodiment provides a diffusion welding method for a backplane and a high-purity metal target, the backplane is a CuCr alloy backplane, the high-purity metal target is a copper target, and the method includes the following steps:

[0073] (1) Prepare the copper target material and the CuCr alloy back plate, and process threads on the welding surface of the CuCr alloy back plate;

[0074] (2) Combine the copper target material and the CuCr alloy back plate, and place the combined material in the metal sheath;

[0075] (3) Carry out degassing treatment to the metal sheath of packing composite material, then the metal sheath is sealed, and the vacuum degree of described degassing treatment is 5 * 10 -2 Pa, the temperature is 120°C, and the time is 4h;

[0076] (4) Place the sealed metal sheath in a cold isostatic press, increase the pressure to 270MPa, keep the pressure for 15min, and complete the cold isostatic pressing treatment after depressurization;

[0077] (5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com