Device for classifying silicon carbide

A technology of silicon carbide and silicon carbide slurry, which is applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of long and complicated process, achieve the effect of continuous feeding and improve classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

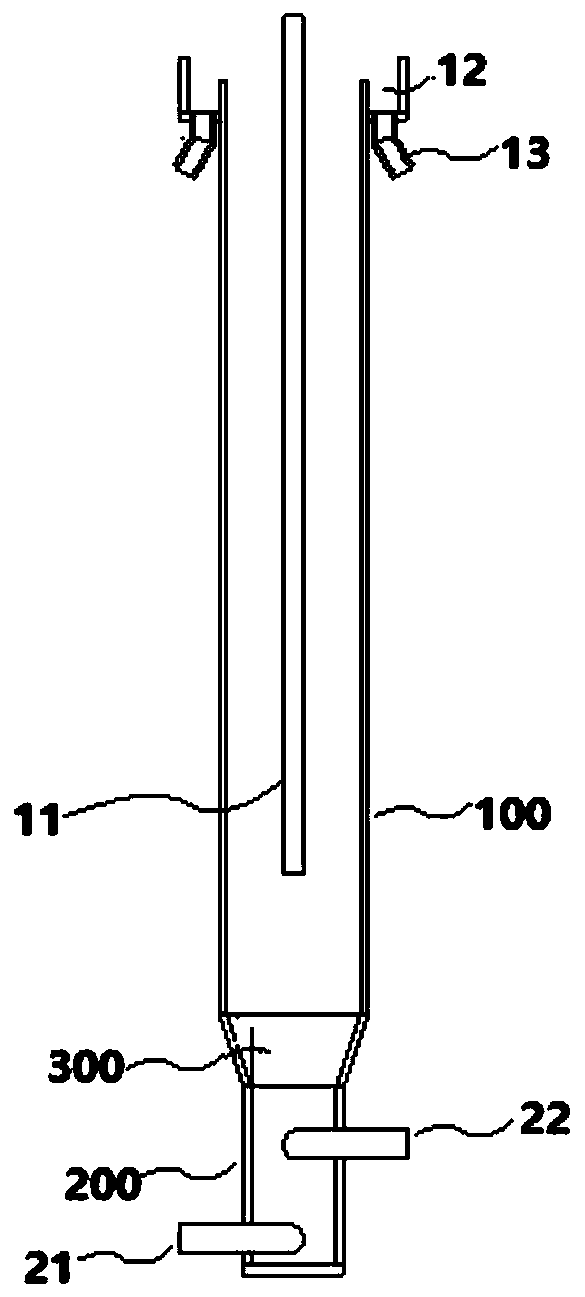

Embodiment 1

[0052] A device for grading silicon carbide comprises, from top to bottom: an upflow column, a bottom flow column and a transition column.

[0053] The top of the upflow column is open, and the upflow column is composed of multi-section sub-columns connected by flanges, including silicon carbide slurry inlet pipe, overflow tank, upflow outlet, middle outflow outlet and water supply pipe. Among them, the silicon carbide slurry inlet pipe extends from the top of the upflow column along the central axis of the upflow column to the inside of the upflow column; the overflow groove is arranged on the outer wall of the top of the upflow column, and in the height direction, the overflow The outer wall of the groove is higher than the outer wall of the upper column; the upper outlet is set at the bottom of the overflow tank; the middle outlet is located on the side wall of the upper column and is lower than the upper outlet in the height direction; the water supply pipe extends into the...

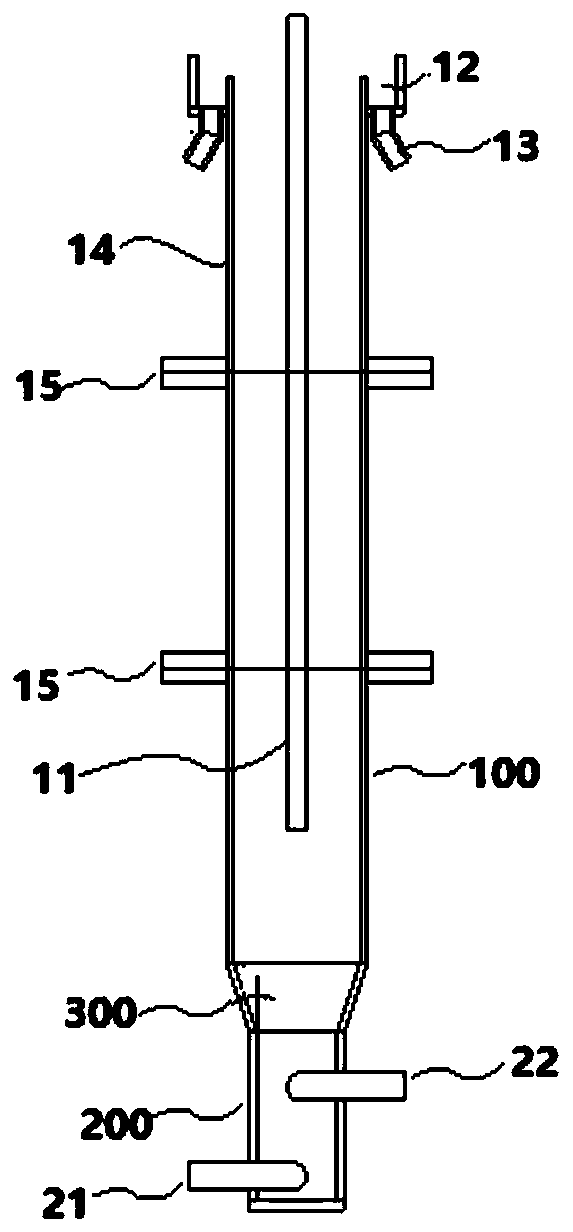

Embodiment 2

[0058] A device for grading silicon carbide comprises, from top to bottom: an upflow column, a bottom flow column and a transition column.

[0059] The top of the upflow column is open, and the upflow column is composed of multi-section sub-columns connected by flanges, including silicon carbide slurry inlet pipe, overflow tank, upflow outlet, middle outflow outlet and water supply pipe. Among them, the silicon carbide slurry inlet pipe extends from the top of the upflow column along the central axis of the upflow column to the inside of the upflow column; the overflow groove is arranged on the outer wall of the top of the upflow column, and in the height direction, the overflow The outer wall of the groove is higher than the outer wall of the upper column; the upper outlet is set at the bottom of the overflow tank; the middle outlet is located on the side wall of the upper column and is lower than the upper outlet in the height direction; the water supply pipe extends into the...

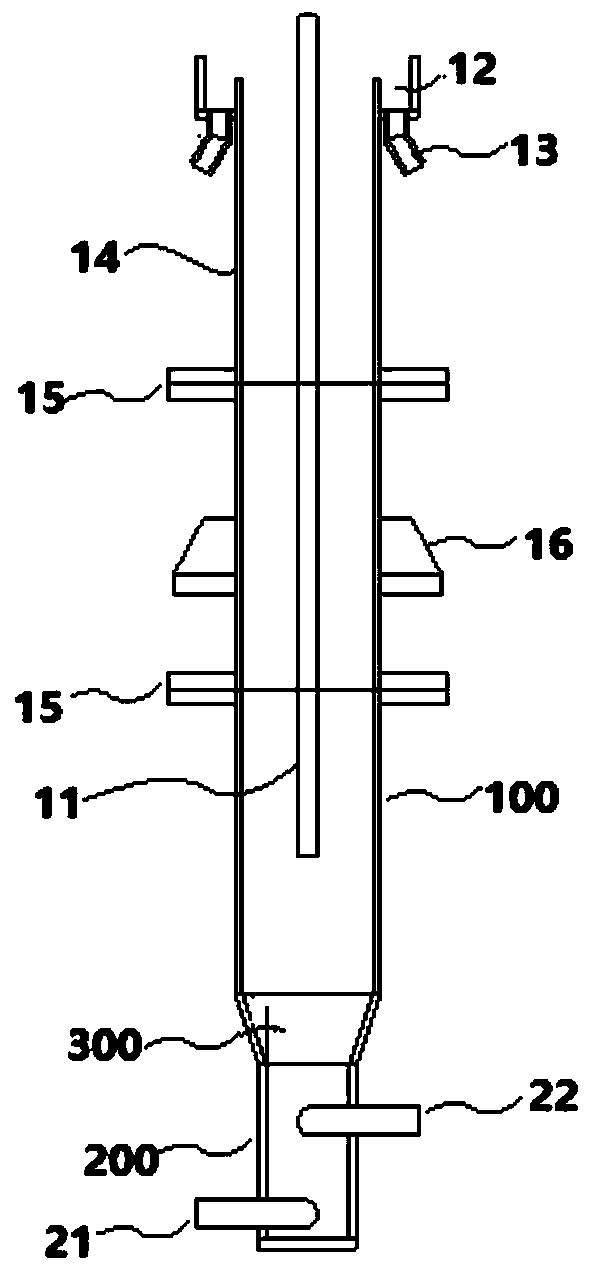

Embodiment 3

[0064] A device for grading silicon carbide comprises, from top to bottom: an upflow column, a bottom flow column and a transition column.

[0065] The top of the upflow column is open, and the upflow column is composed of multi-section sub-columns connected by flanges, including silicon carbide slurry inlet pipe, overflow tank, upflow outlet, middle outflow outlet and water supply pipe. Among them, the silicon carbide slurry inlet pipe extends from the top of the upflow column along the central axis of the upflow column to the inside of the upflow column; the overflow groove is arranged on the outer wall of the top of the upflow column, and in the height direction, the overflow The outer wall of the groove is higher than the outer wall of the upper column; the upper outlet is set at the bottom of the overflow tank; the middle outlet is located on the side wall of the upper column and is lower than the upper outlet in the height direction; the water supply pipe extends into the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com