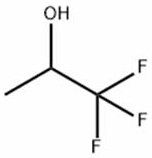

Preparation method of trifluoroisopropanol

A technology for trifluoroisopropanol and trifluoroacetaldehyde is applied in the preparation of 1,1,1-trifluoro-2-propanol and in the field of preparation of trifluoroisopropanol, which can solve the problems of unsuitable industrial production and raw materials. Inflammable and explosive, large equipment investment and other problems, to achieve the effect of high yield, short reaction process and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the dry reaction kettle, 11.4g (0.075mol) of cesium fluoride was added under the protection of nitrogen, the temperature was lowered to -10°C, and 900ml (1.8mol) of 2.0mol / L tetrahydrofuran solution of methylmagnesium chloride was added under stirring, and then three A mixture of 147.03g (1.50mol) of fluoroacetaldehyde and 375mL of tetrahydrofuran. After dropping, slowly warm up to 0°C and react for 10h. Add 3ml of water to quench the reaction and purify to obtain 160.33g of colorless liquid namely 1,1,1-trifluoro-2-propanol, GC purity 99.2% (area normalization method), yield 95.01%

Embodiment 2

[0026] The ratio of methylmagnesium chloride to trifluoroacetaldehyde was changed to 1:1, and the others were the same as in Example 1 to synthesize 1,1,1-trifluoro-2-propanol with a yield of 95.20%.

Embodiment 3

[0028] The ratio of methylmagnesium chloride to trifluoroacetaldehyde was changed to 1:1.2, and the others were the same as in Example 1 to synthesize 1,1,1-trifluoro-2-propanol with a yield of 96.34%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com