Multi-point-position welding flux feeding device of electronic device welding device

A technology of electronic equipment and feeding device, applied in the field of multi-point solder feeding device, can solve the problems of inability to feed materials at multiple points at the same time, single feeding, etc., and achieve the effects of simple structure, timely transportation and convenient dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings. Embodiments of the present invention include, but are not limited to, the following examples.

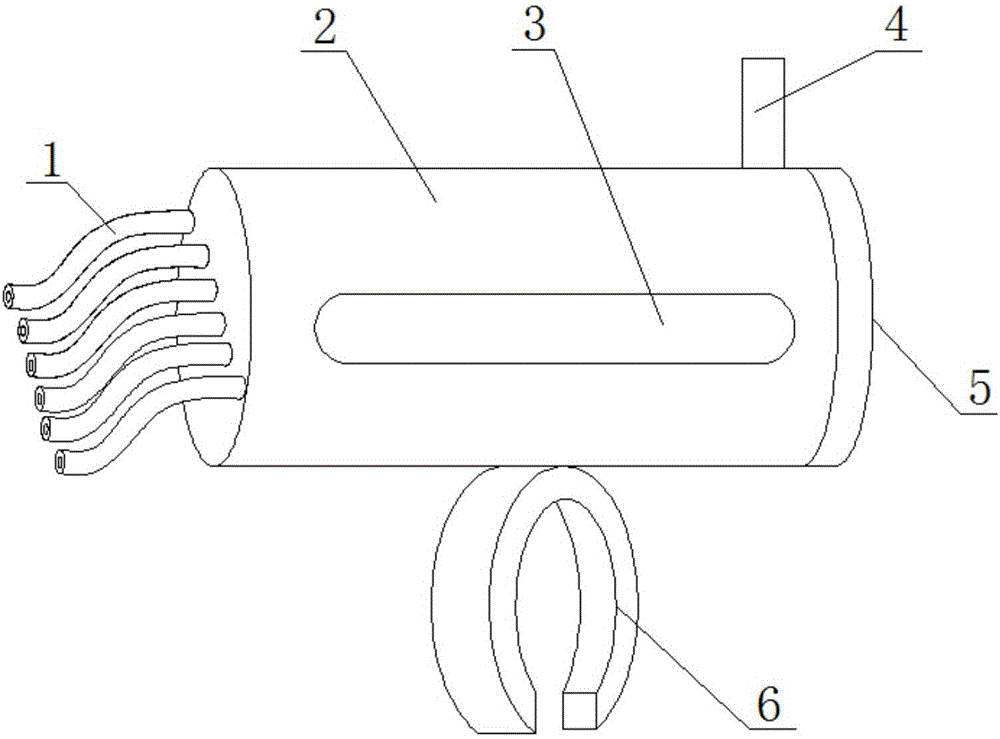

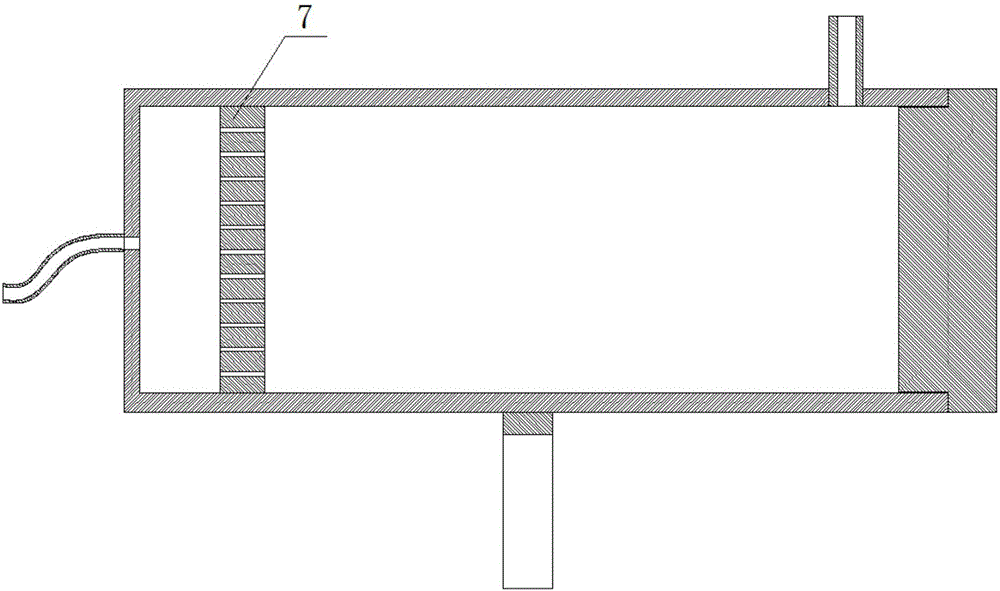

[0015] Such as figure 1 , figure 2 As shown, the multi-point solder feeding device of the electronic equipment welding device includes a heat-conducting metal solder cylinder 2 for filling solder, one end of the heat-conducting metal solder cylinder 2 is provided with a threaded sealing cover 5 and the other end is connected to a metal hose 1 , the metal hose 1 is evenly arranged in a plurality of straight lines, and the heat-conducting metal solder cylinder 2 is located inside the connected end of the metal hose 1. A filter plate 7 with filter holes is also arranged inside, and the circumference of the heat-conducting metal solder cylinder 2 is along the axis A transparent observation strip 3 is provided, and a heat-conducting metal elastic buckle 6 is provided on the circ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com