Fully automatic transfer flat truck

A fully automatic, flat car technology, applied in the field of medical equipment, can solve problems such as poor sanitation, inconvenient operation, and accidental slipping of patients, and achieve good shock absorption performance, avoid discomfort, and reduce the effect of turbulence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

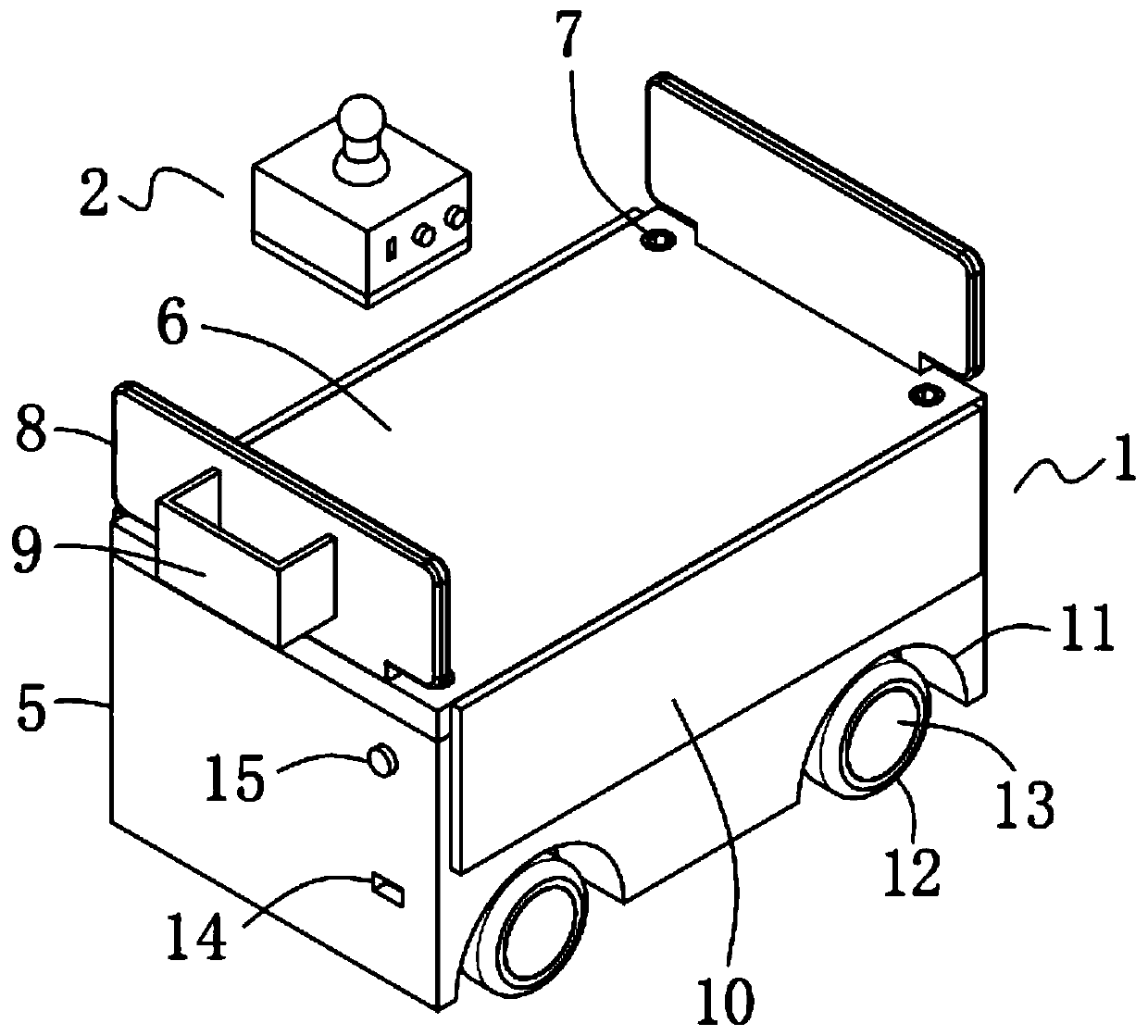

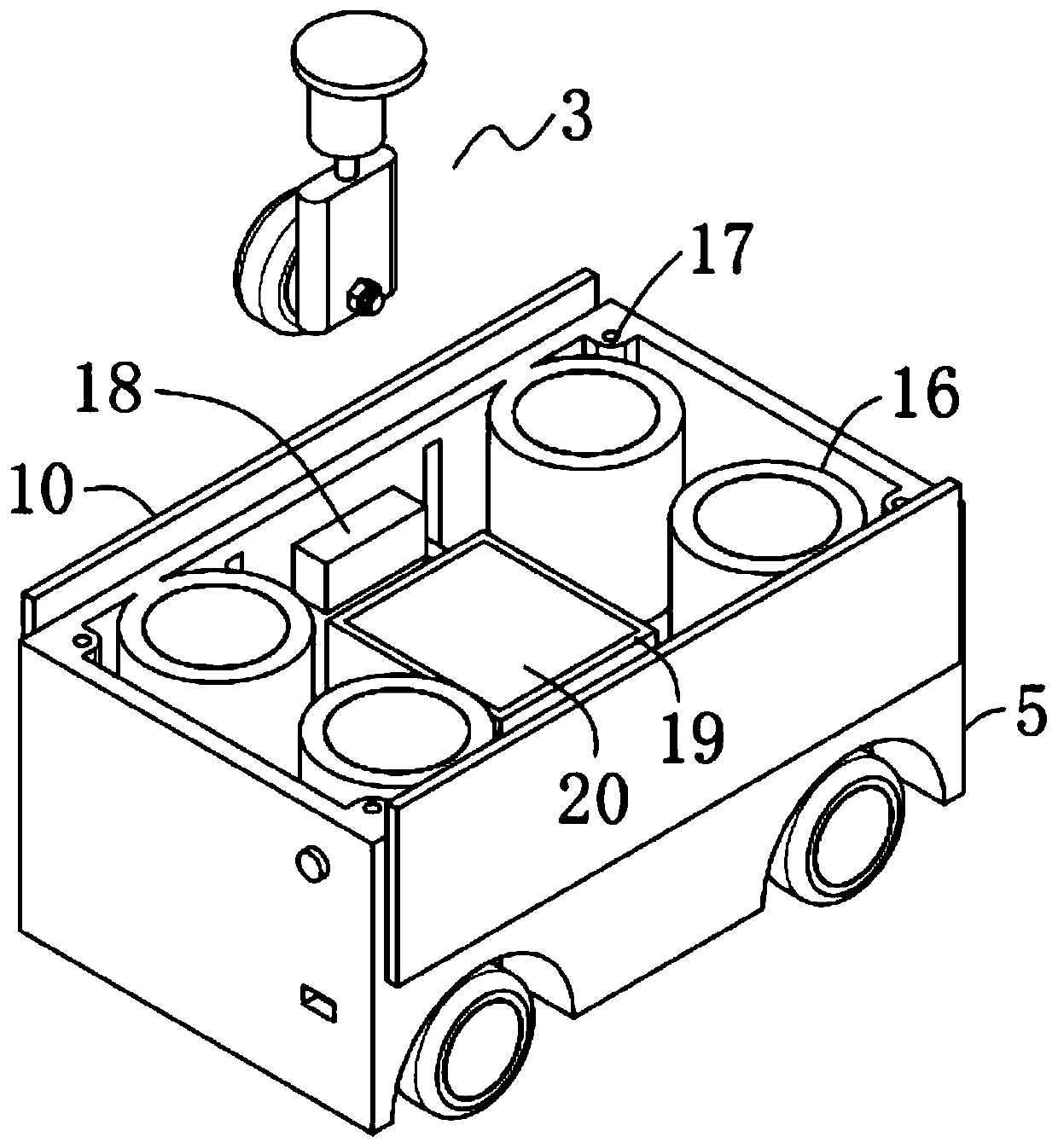

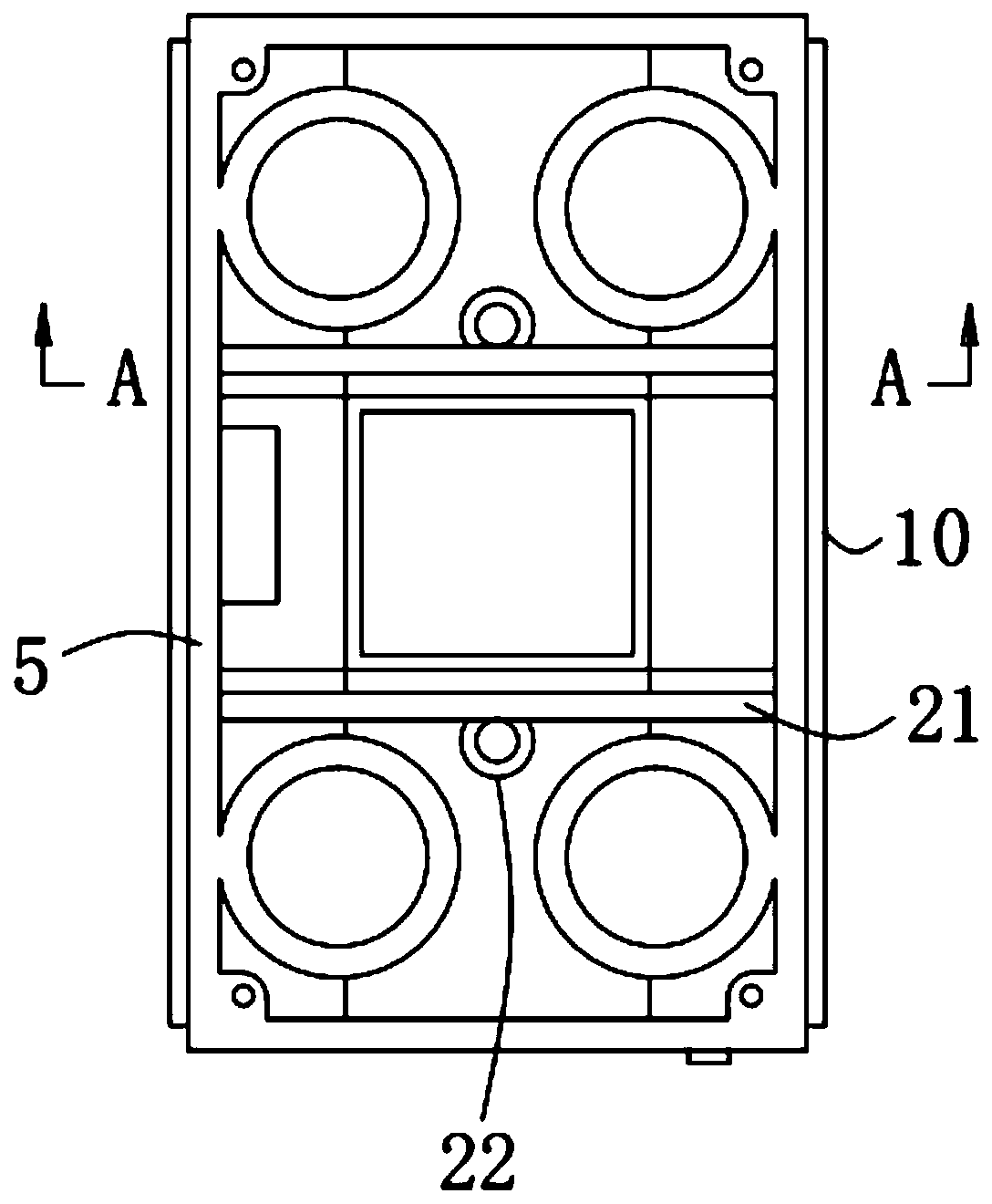

[0057] A fully automatic transfer flat car, such as Figure 1-2 As shown in and 5-6, it includes a transfer flat car body 1, the transfer flat car body 1 includes a vehicle frame 5, a support plate 6 and four sets of walking mechanisms 3, the vehicle frame 5 is a square shell structure, and the The bottom of the vehicle frame 5 is aligned with four semicircular fitting grooves 11 symmetrically aligned with its two side edges, and the interior of the vehicle frame 5 is fixedly installed with four fixing parts that match the semicircular fitting grooves 11. Cylinder 16, the four fixed cylinders 16 are set corresponding to the four semicircular fitting grooves 11 respectively, and the corresponding fixed cylinder 16 and the corresponding semicircular fitting groove 11 are equally spaced. A guide channel 24 is provided, the support plate 6 is fixedly installed on the upper part of the vehicle frame 5 through bolts 7, and the four sets of running mechanisms 3 are respectively fixed...

Embodiment 2

[0080] The difference from Example 1 is that the upper surface of the support plate 6 is also provided with a protective layer, and the protective layer is prepared by the following method:

[0081] Take the following raw materials and weigh them by weight: 18 parts of epoxy resin, 8 parts of calcium carbonate powder, 10 parts of nano silver powder, 12 parts of melamine resin, 8 parts of titanium dioxide powder, 15 parts of polyurethane, 3 parts of paraffin wax, 2 parts of alcohol ester twelve , 2 parts of triethanolamine, 2 parts of emulsified silicone oil and 35 parts of water;

[0082] S1. Add the weighed paraffin, alcohol ester dodecane, triethanolamine, emulsified silicone oil and water into the mixer and stir for 10 minutes at a stirring speed of 400r / min to prepare a mixed solution;

[0083] S2, adding epoxy resin, calcium carbonate powder, nano-silver powder, melamine resin, titanium dioxide powder and polyurethane into a pulverizer for pulverization until the particle...

Embodiment 3

[0089] The difference with embodiment 2 is the preparation of protective layer, and its specific preparation method is as follows:

[0090] Take the following raw materials and weigh them by weight: 22 parts of epoxy resin, 10 parts of calcium carbonate powder, 11 parts of nano silver powder, 14 parts of melamine resin, 9 parts of titanium dioxide powder, 18 parts of polyurethane, 4 parts of paraffin wax, 3 parts of alcohol ester twelve , 3 parts of triethanolamine, 3 parts of emulsified silicone oil and 40 parts of water;

[0091] S1. Add the weighed paraffin, alcohol ester dodeca, triethanolamine, emulsified silicone oil and water into the mixer and stir for 13 minutes at a stirring speed of 500r / min to prepare a mixed solution;

[0092] S2, adding epoxy resin, calcium carbonate powder, nano-silver powder, melamine resin, titanium dioxide powder and polyurethane into a pulverizer for pulverization until the particle diameter of the material is not greater than 100nm, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com