Cement-based neutron shielding material and preparation method thereof

A shielding material, cement-based technology, applied in the direction of shielding, greenhouse gas reduction, reactors, etc., can solve the problems of cement-based neutron shielding materials such as large layering, affecting neutron shielding performance, and low shielding efficiency, so as to improve the use of Effects of temperature range, improved working performance, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention also provides a method for preparing a cement-based neutron shielding material, which includes the following steps:

[0030] (1) Prepare materials in parts by weight;

[0031] (2) Mix the polymer and water uniformly to obtain an emulsion, add composite cement, carbon fiber and polycarboxylic acid water-reducing agent to the emulsion, and mix uniformly to obtain a gel-like matrix material with good fluidity; the shielding absorption powder The powder and the PVA powder binder are mixed evenly, and then the dried graded graphite particles are added and mixed evenly to obtain a functional aggregate;

[0032] (3) The base material and the functional aggregate are uniformly mixed according to the mass ratio of 1:0.45 to 0.55 to obtain the finished product.

[0033] Neutron shielding ray shielding is generally divided into two processes. First, high-energy neutrons and heavy elements (Pb, Ba, etc.) undergo inelastic scattering to attenuate thei...

Embodiment 1

[0037] Embodiment 1 of the present invention provides a matrix material in a cement-based neutron shielding material. The matrix material includes the following components by weight: 90 parts by weight of CA-50 aluminate cement, 10 parts by P·O 42.5 cement, 5 parts of polymer (the mass ratio of H-223A and H-223B in the polymer is 1:2), 0.8 part of polycarboxylic acid water reducing agent, and carbon fiber. The weight of carbon fiber is 3% of the weight of the matrix material. The ratio is 0.45.

[0038] The matrix material is prepared by the following method: first mix epoxy resin H-223A and epoxy curing agent H-223B, add water and stir to form an emulsion, and then add CA-50 aluminate cement, P·O 42.5 Portland cement and The carbon fiber is fully stirred, and the polycarboxylic acid water reducing agent is slowly added during the stirring process to finally form a gel-like matrix material with good fluidity.

Embodiment 2~9

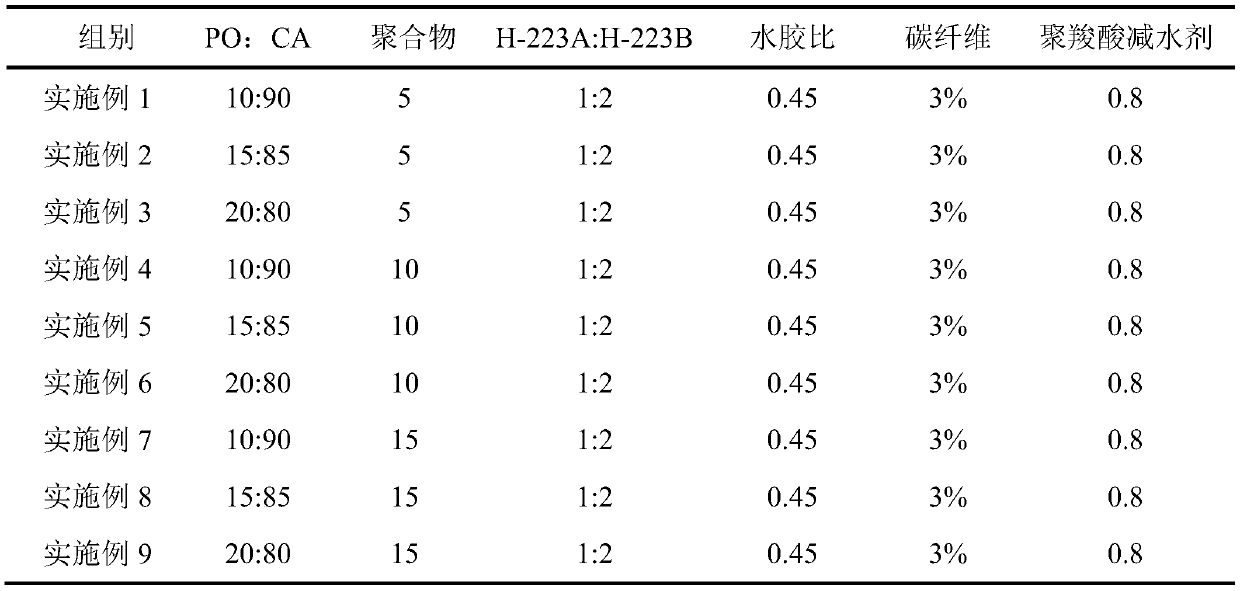

[0040] The base materials of Examples 2-9 were prepared according to the method of Example 1. The raw materials and preparation methods were the same as those of Example 1. The difference was that the ratio of the raw materials was different. The ratios of the base materials of Examples 1-9 are shown in Table 1.

[0041] Table 1 The proportion of the base materials of Examples 1-9 (parts by weight)

[0042]

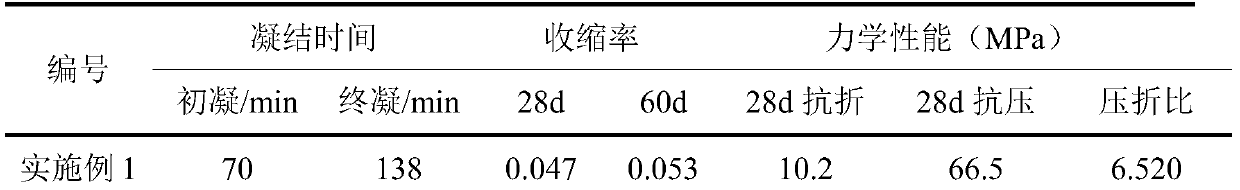

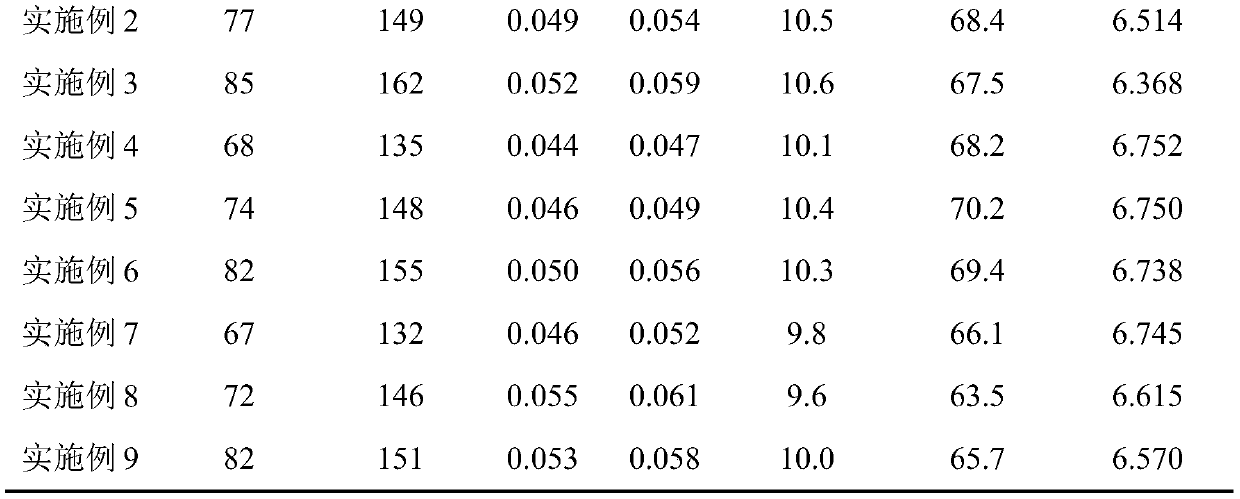

[0043] The physical and mechanical properties of the matrix materials prepared in Examples 1-9 are shown in Table 2.

[0044] Table 2 Physical and mechanical properties of the matrix materials of Examples 1-9

[0045]

[0046]

[0047] It can be seen from Table 2 that the initial setting time of the matrix material is between 67 and 85 minutes, and the final setting time is between 132 and 162 minutes. The actual initial setting time of P·O 42.5 cement alone is 160~190min, and the final setting time is 240~260min; the initial setting time of CA-50 aluminate cement alone is 30~40m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com