Optical film of multilayer structure

A technology of optical thin film and multi-layer structure, applied in the field of communication materials, can solve the problem of poor light directivity, and achieve the effect of high transmittance, improved directivity, and enhanced reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

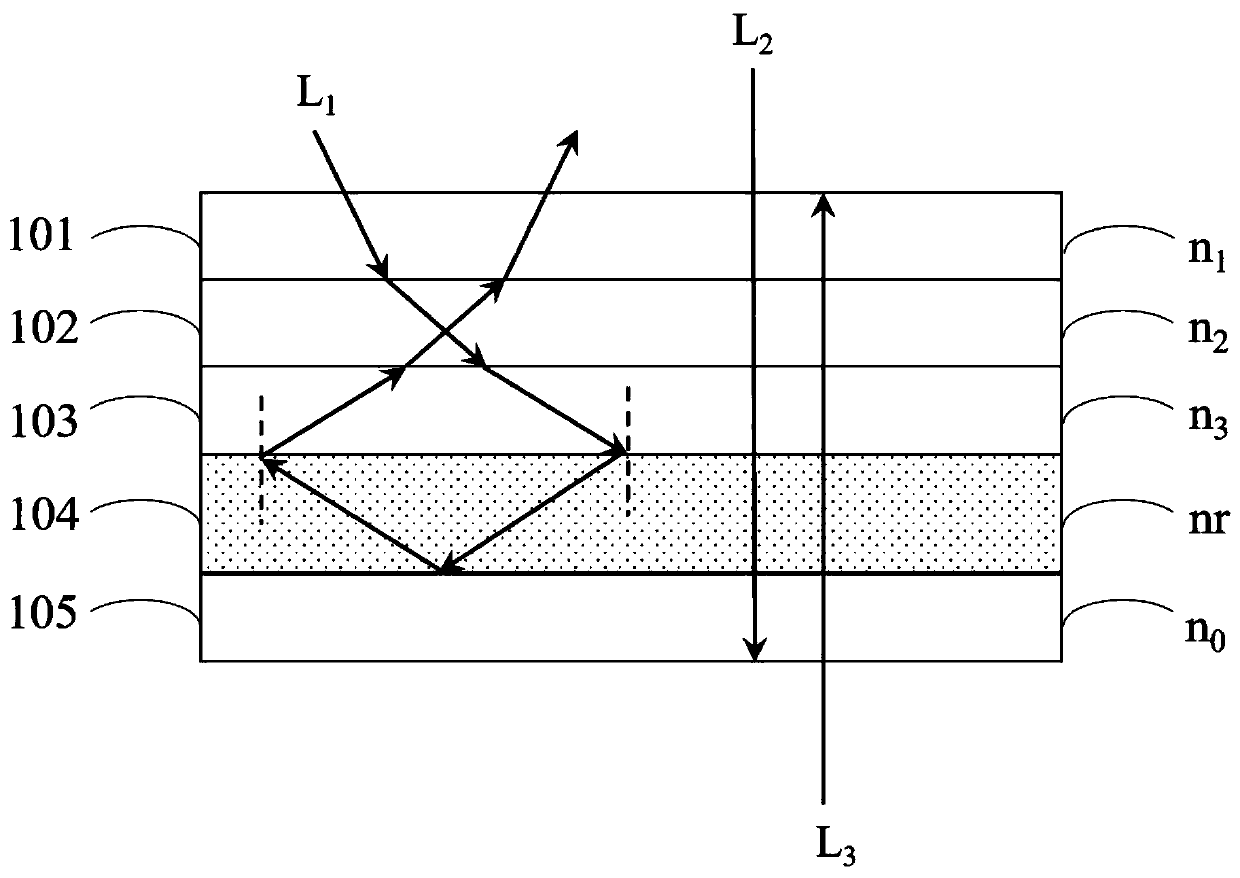

[0026] Please refer to figure 1 , is a cross-sectional view of the multilayer optical film in Example 1 of the present invention, which includes a stack of four positive refractive index microlayers 101, 102, 103, 105 and one negative refractive index microlayer 104. The upper surface of the positive refractive index microlayer 101 is the first surface, and the lower surface of the positive refractive index microlayer 105 is the second surface. In Example 1 of the present invention, the effect of L1 light passing through the multi-layer stack with different positive refractive index microlayers and negative refractive index microlayers is as follows: figure 1 shown. The negative index microlayer 104 exhibits a negative index of refraction nr for visible light. The first surface that is arranged in parallel and the second surface on the opposite side pass the refractive index n of 3 positive refractive index microlayers 101, 102, 103 1 , n 2 , n 3 Decreasing in turn, the r...

Embodiment 2

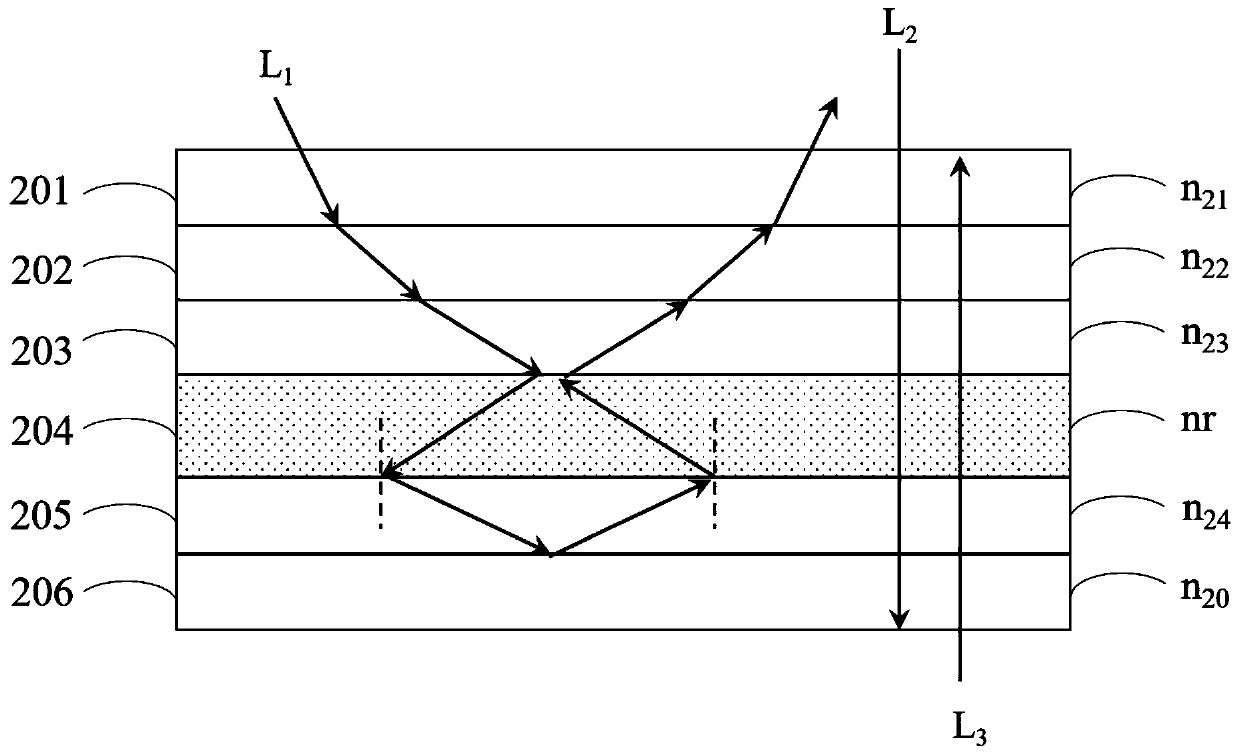

[0031] Please refer to figure 2 , is a cross-sectional view of the multilayer optical film of Example 2 of the present invention. The similarities and differences between Example 2 and Example 1 will be described below. figure 2 The structure of the multilayer optical film comprises five layers of positive refractive index microlayers 201, 202, 203, 205, 206 and one layer of negative refractive index microlayers 204. The upper surface of the positive refractive index microlayer 201 is the first One surface, the lower surface of the positive refractive index microlayer 206 is the second surface. In Example 2 of the present invention, the effect of light L1 passing through a multilayer stack with different positive refractive index microlayers and negative refractive index microlayers is as follows: figure 2 shown. The negative index microlayer 204 exhibits a refractive index nr for visible light. The first surface arranged in parallel and the second surface on the opposi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com