A suction and discharge structure for a compressor

A technology of suction and exhaust, compressor, applied in the field of compressors, can solve the problems of reducing the exhaust efficiency of the compressor, reducing the suction efficiency of the compressor, collision between the movement and the casing, etc. Gas efficiency, the effect of improving gas transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

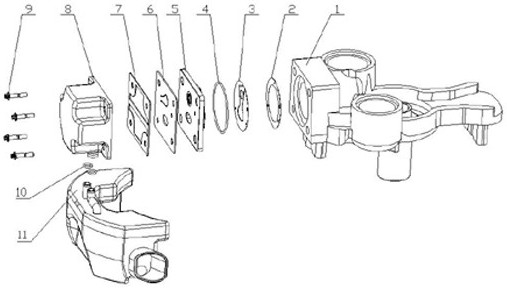

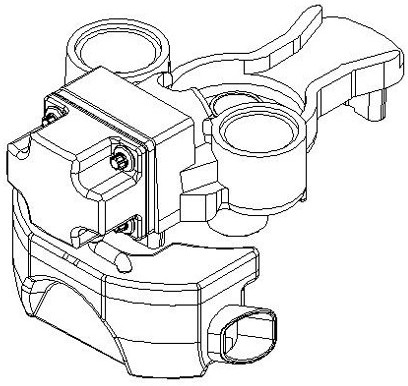

[0065] Attached below Figure 1-30 The present invention is described in further detail with specific embodiment:

[0066] A suction and exhaust structure for a compressor, including a crankcase 1, a valve plate sealing gasket 2, a suction valve plate 3, a valve plate sealing ring 4, a valve plate 5, an exhaust valve plate 6, and a cylinder head gasket Sheet 7, cylinder head 8, mounting screw 9, muffler sealing ring 10, suction muffler 11,

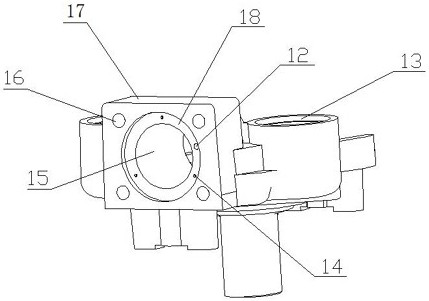

[0067] The crankcase 1 includes a cylinder block 17 and an exhaust buffer cavity 13, the exhaust buffer cavity 13 is cast on the right side of the cylinder block 17, and the center of the end face of the cylinder block 17 is milled with a stepped hole 18, and the stepped hole The inside of 18 is drilled with cylinder hole 15, and the step surface of step hole 18 is drilled with valve plate positioning hole 14 and exhaust hole 12, and is drilled with threaded hole 16 on the four angles of described cylinder block 17 end faces, and describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com