Waste electronic circuit board or electroplating sludge smelting flue gas treatment method

An electronic circuit board, electroplating sludge technology, applied in the field of recycling and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

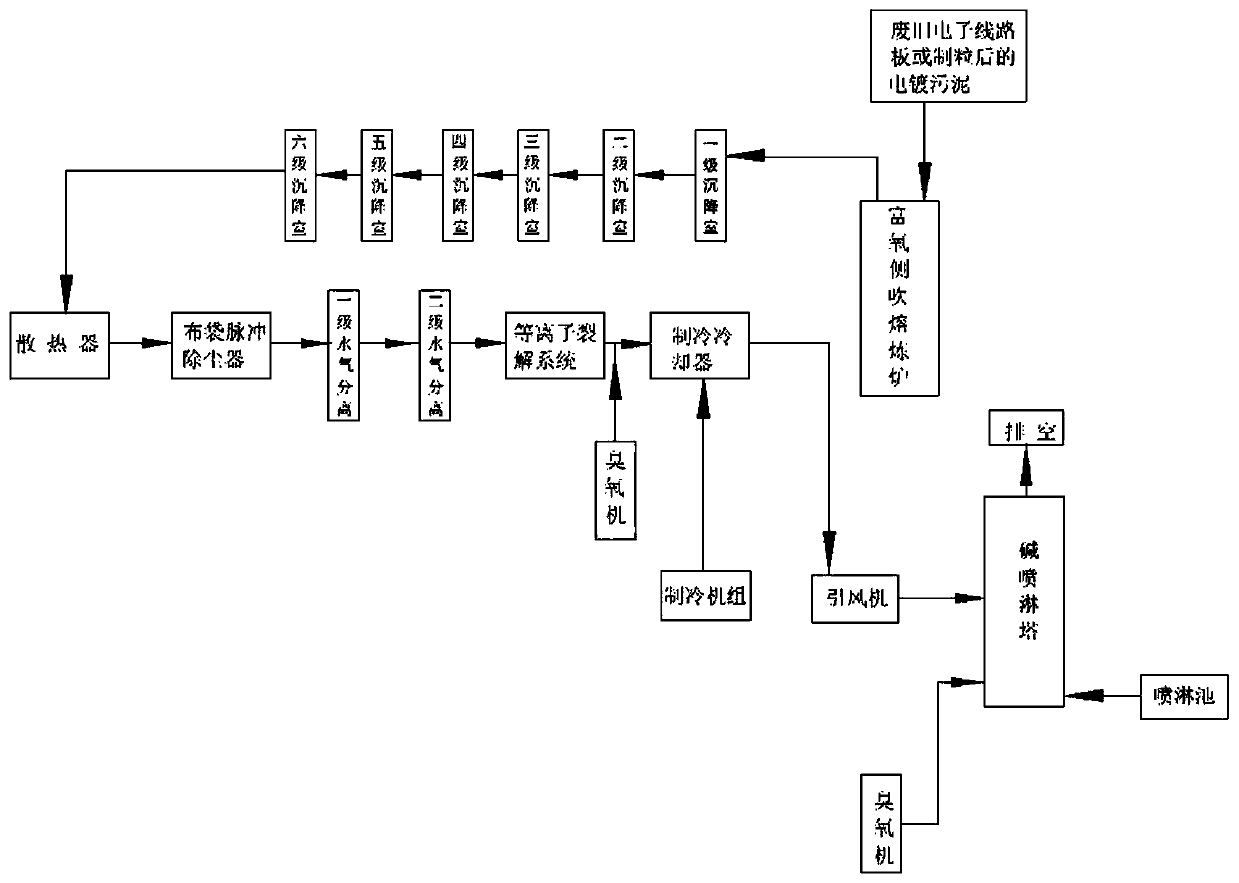

[0029] The processing method of waste electronic circuit board smelting flue gas of the present invention, the detailed steps of this processing method are as follows:

[0030] a. First put waste electronic circuit boards into an oxygen-enriched side-blowing smelting furnace for smelting, the smelting temperature is 1300°C, and the smelting time is 8 minutes; after smelting, a metal phase is obtained (the metal phase contains copper, tin, nickel, lead, iron and All precious metals) and soot (the soot contains carbon dioxide, water vapor, hydrogen halide and sulfur, nitrogen oxides, and oxides formed by zinc and some lead), the metal phase enters the smelting system for recycling and reuse; the resulting soot enters the next process;

[0031] b. The dust formed after smelting in step a is introduced into the first-level settling chamber, the second-level settling chamber, the third-level settling chamber, the fourth-level settling chamber, the fifth-level settling chamber and th...

Embodiment 2

[0038] The treatment method of electroplating sludge smelting flue gas of the present invention, the detailed steps of this treatment method are as follows:

[0039] a. First, the electroplating sludge is made into particles of about 50 mm through a granulator, and put into an oxygen-enriched side-blowing smelting furnace for smelting. The smelting temperature is 1300 ° C, and the smelting time is 5 minutes; after smelting, the metal phase (the metal phase contains Copper, tin, nickel, lead, iron and all precious metals) and dust (the dust contains carbon dioxide, water vapor, hydrogen halide and sulfur, nitrogen oxides, and oxides formed by zinc and some lead), and the metal phase enters the smelting system for recycling. Utilization; the resulting smoke enters the next process;

[0040] b. The dust formed after smelting in step a is introduced into the first-level settling chamber, the second-level settling chamber, the third-level settling chamber, the fourth-level settling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com