Waterborne gloss oil and preparation method and application thereof

A water-based varnish, water-based technology, applied in the field of coatings, can solve the problem of not being able to improve the performance of scratch resistance and hardness, and achieve the effects of good appearance and gloss, high wet film thickness, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

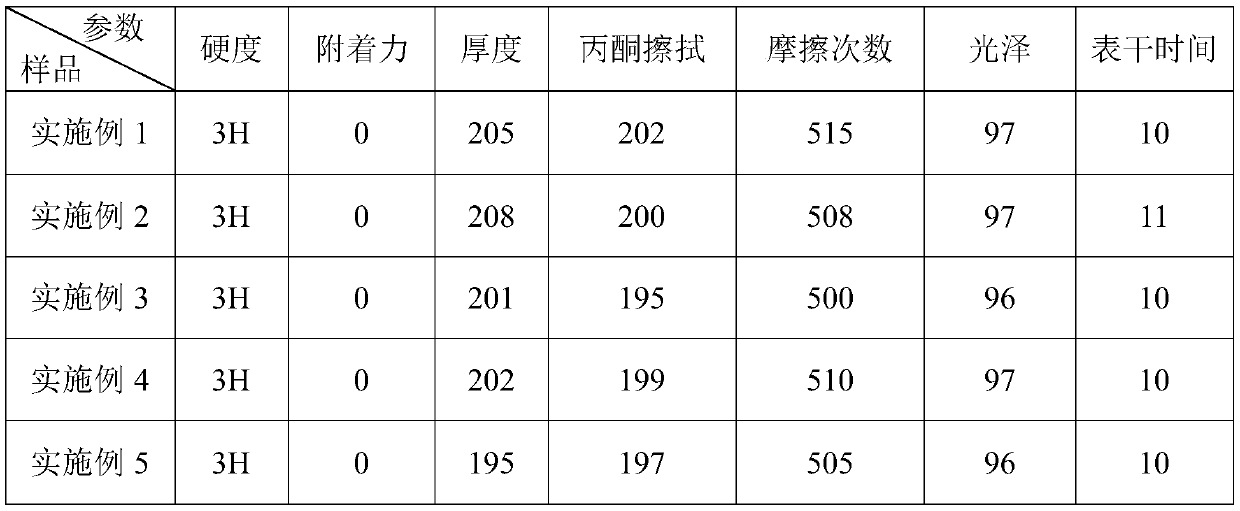

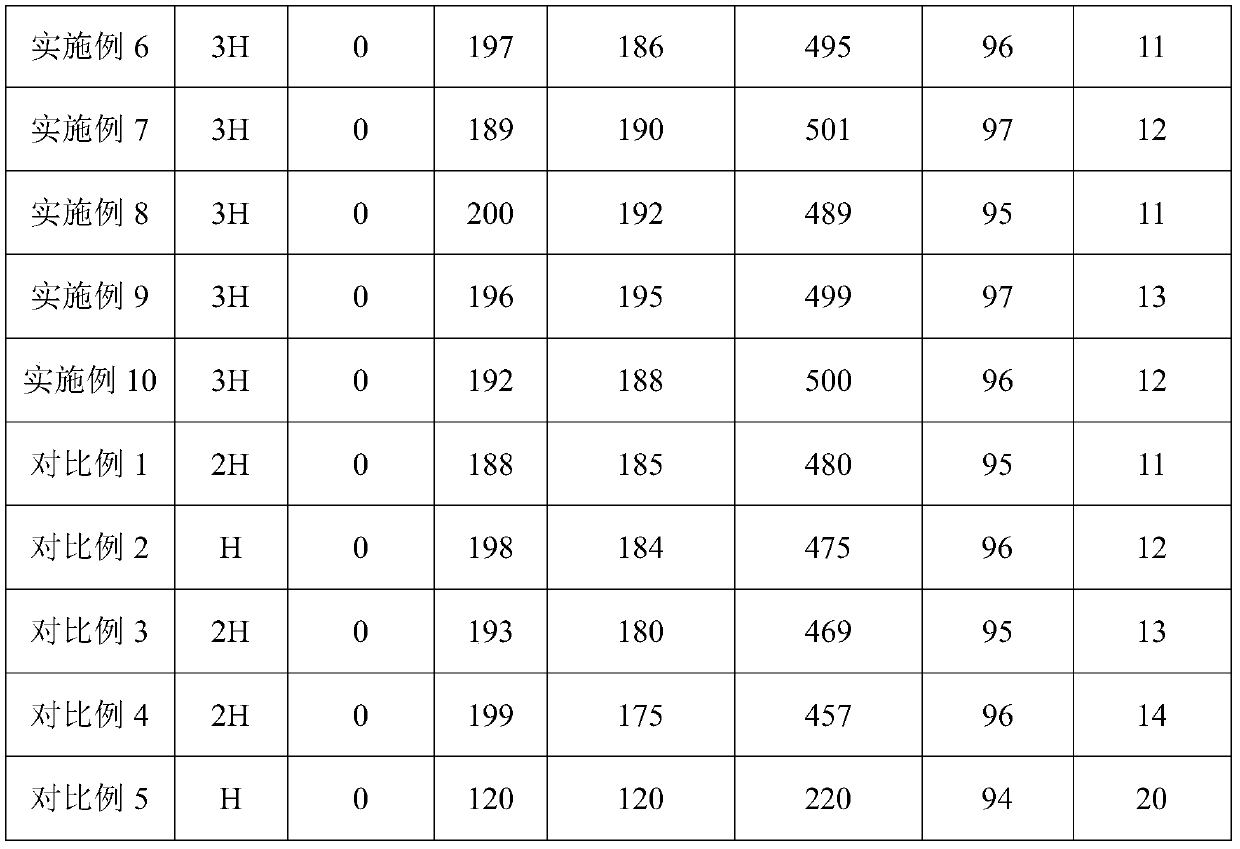

Examples

Embodiment 1

[0061] The present embodiment provides a water-based varnish, comprising the following components in parts by weight:

[0062] 30 parts of Wanhua 2042, 7 parts of Allnex 6717, 18 parts of water-dispersible isocyanate curing agent, 1 part of Tinuvin1130, 2 parts of Dow Corning DC-51, 0.2 parts of N,N-dimethylethanolamine, 4 parts of ethylene glycol butyl ether 0.5 parts of BYK420, 0.4 parts of BYK34000, 0.4 parts of BYK019, 0.3 parts of BYK346, 25 parts of water.

Embodiment 2

[0064] The present embodiment provides a water-based varnish, comprising the following components in parts by weight:

[0065] Wanhua 2043 50 parts, allnex 6777 12 parts, water dispersible isocyanate curing agent 20 parts, Tinuvin2921.5 parts, Dow Corning DC-57 1 part, ammonia water 0.1 part, diethylene glycol butyl ether 12 parts, BYK4251 parts, 0.7 parts of BYK3455, 0.8 parts of BYK023, 0.6 parts of BYK333, 30 parts of water.

Embodiment 3

[0067] The present embodiment provides a water-based varnish, comprising the following components in parts by weight:

[0068] Wanhua 2035 35 parts, Leo LA-606 5 parts, water dispersible isocyanate curing agent 12 parts, Tinuvin384-2 0.5 parts, BYK996 3.5 parts, ethanolamine 0.3 parts, ethylene glycol methyl ether acetate 3 parts, BYK430 0.3 parts 0.1 part of Tego 270, 0.05 part of BYK032, 0.05 part of BYK381, 20 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com