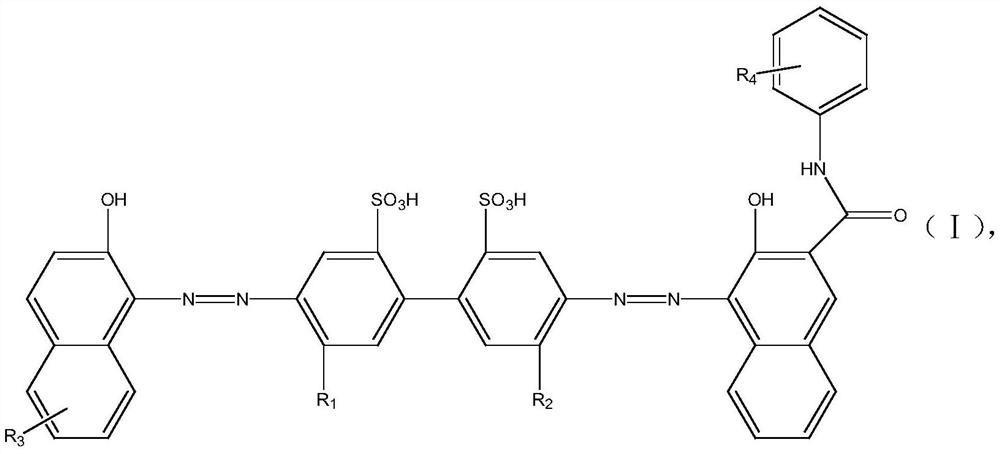

A kind of environmentally friendly disazo acid red dye and preparation method thereof

A bisazo and acid red technology, applied in the field of fabric organic dyes, can solve the problems of difficult coloring, low dyeing improvement rate, dark dyeing color, etc., to achieve convenient production control, simple preparation process, and high yield of product dyes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

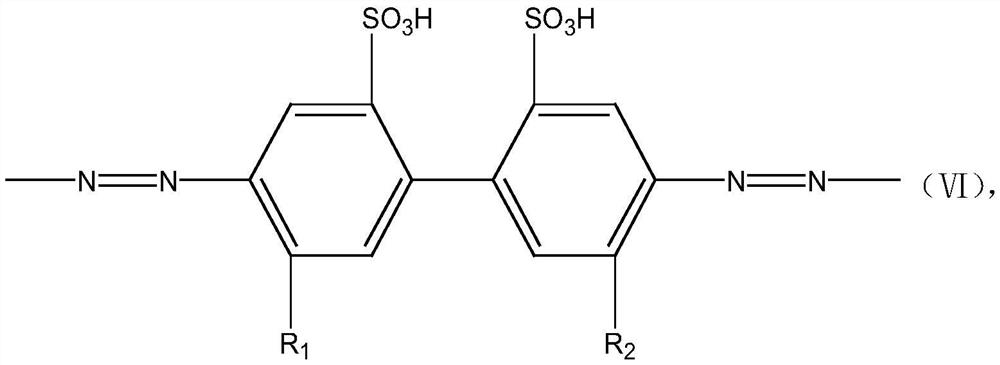

Method used

Image

Examples

Embodiment 1

[0074] A kind of environmentally friendly disazo acid red dye, it has the chemical structure of general formula (I), wherein R 1 for hydrogen, R 2 for hydrogen, R 3 for hydrogen, R 4 for hydrogen.

[0075] The preparation method steps of the disazo acid red dye of embodiment one are as follows,

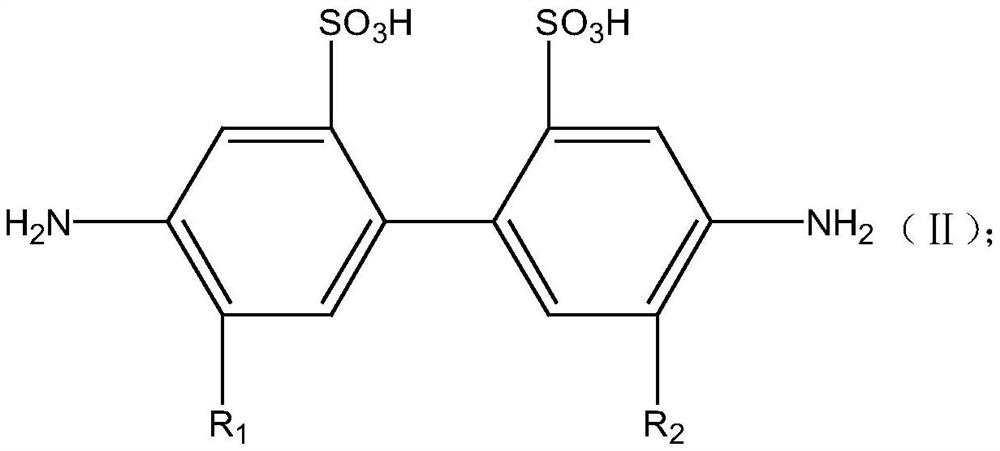

[0076] T1: Take 150ml of deionized water, add 17.2g of 4,4-diaminobiphenyl-2,2-disulfonic acid, heat up to 60°C, then add 30wt% liquid caustic soda solution (sodium hydroxide solution), stir well Finally, add 3.55g sodium nitrite for subsequent use, and make a part of the pre-prepared solution;

[0077] T1: Take 100ml of ice-water mixture, add 10g of hydrochloric acid, start the stirrer to mix the mixture, cool down to 0-5°C, then maintain the temperature at 0-5°C, then add a portion of the pre-prepared solution into the beaker, pre-prepared The time for adding the solution is 5 minutes. After the addition, the temperature of the mixed liquid is kept at 5-8°C, and the reaction is...

Embodiment 2

[0084] A kind of environmentally friendly disazo acid red dye has the chemical structure of general formula (I), wherein R 1 is methyl, R 2 is methyl, R 3 for hydrogen, R 4 for hydrogen.

[0085] The disazo acid red dye preparation method step of embodiment two is based on the basis of embodiment one, and its difference is that in T1, 5,5-dimethylbenzidine-2,2-disulfonic acid Substituting 4,4-diaminobiphenyl-2,2-disulfonic acid for synthesis to prepare the product disazo acid red dye (P2).

[0086]

Embodiment 3

[0088] A kind of environmentally friendly disazo acid red dye has the chemical structure of general formula (I), wherein R 1 is methoxy, R 2 is methoxy, R 3 for hydrogen, R 4 for hydrogen.

[0089] The steps of the preparation method of disazo acid red dye in Example 3 are based on the basis of Example 1. The difference is that in T1, 5,5-dimethoxybenzidine-2,2-bis Sulfonic acid replaces 4,4-diaminobiphenyl-2,2-disulfonic acid to synthesize the product bis-azo acid red dye (P3).

[0090]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com