A method for fabricating thick-film thermocouples on three-dimensional surfaces based on laser direct writing process

A laser direct writing, three-dimensional surface technology, applied in the field of laser micromachining and film sensor, can solve problems such as excessive roughness, peeling, limited workpiece size, etc., to achieve the effect of breaking through application limitations and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

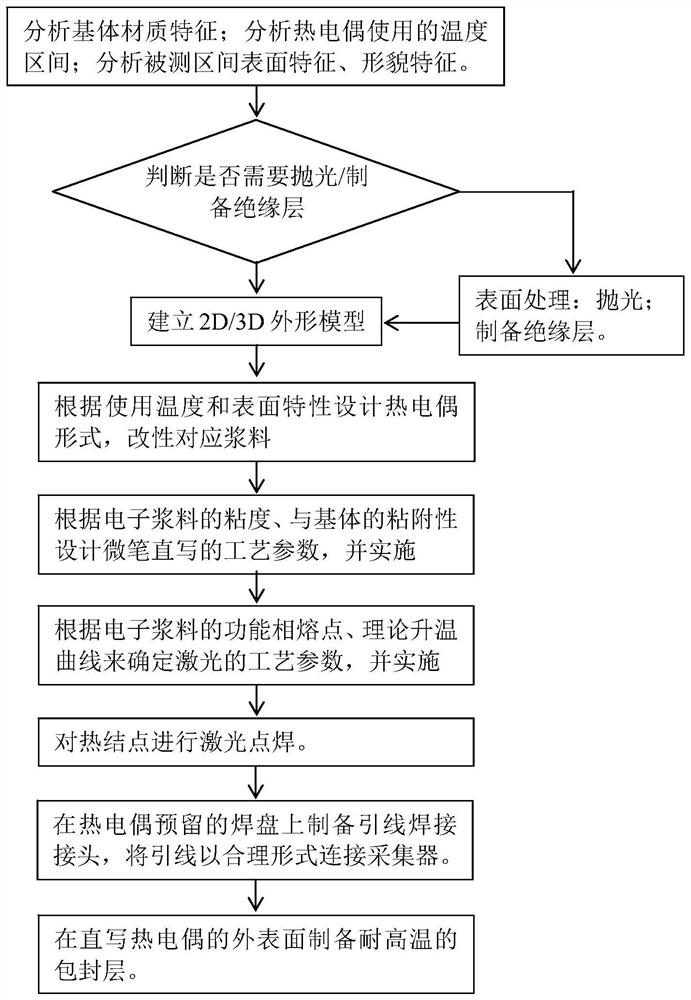

Method used

Image

Examples

preparation example Construction

[0059] 4. Preparation of Direct Write Wires

[0060] Coat the Pt / PtRh electronic paste on the surface of the dielectric layer with a micro-pen, and dry the wires on the curved surface at 80°C to 150°C for 10min to 20min. Drying can promote the shape retention and curing of the electronic paste. For wires in flat parts, you can choose not to dry, and directly write with laser.

[0061] Then, the coaxial laser is used to carry out laser cladding along the path running with the micropen. During the cladding process, the interaction between the laser and the electronic paste is used to promote the discharge of the organic phase (removal of glue), so that the Pt / PtRh Remelt solidification and vitrification of the inorganic phase (high temperature adhesive). The technological parameters adopted by the micropen and the laser are determined according to the physical models in the corresponding steps. For thermocouple samples on a flat surface, the preparation time shall not exceed 3...

Embodiment 1

[0068] Example 1 Preparation of a sensor array for nickel-based superalloy turbine blades with a surface temperature of 1000°C

[0069] Select two kinds of commercial Pt / PtRh electronic pastes, and adjust the viscosity of the two pastes to the interval of 50-150mPa s through diluents, then by mixing diluents (including but not limited to terpineol, ethanol, etc.), or Thickener (including but not limited to carboxymethyl cellulose, etc.), to adjust the viscosity of the electronic paste to 50-150mPa·s.

[0070] Use a three-dimensional scanner to read the characteristic values of the surface topography and size of the turbine blade, and use computer-aided design software (such as ProE software) to analyze these characteristic values as the design basis. The design objects include but are not limited to the windward edge of the blade. Use computer-aided design software to design the motion trajectory of the thermal spraying ABB robot arm and the Huake Micro Pen direct writing...

Embodiment 2

[0073] Example 2 Ceramic Matrix Composite (CMC) Turbine Blade Surface 1200°C Sensor Array

[0074] To detect the surface roughness of CMC turbine blades, local or overall polishing is required for ceramic surfaces with an average roughness Ra>0.7μm. Polishing methods include but are not limited to laser polishing, mechanical polishing and chemical polishing. Prioritize stress-free polishing of the surface where the thermocouple is to be prepared using a CNC process. The surface roughness of the polished plane is Ra≤0.7μm.

[0075] 1. Material modification

[0076] Select commercial Pt / PtRh two kinds of electronic pastes, measure their viscosities respectively, the viscosities of Pt and PtRh two kinds of electronic pastes are respectively 45mPa·s and 200mPa·s, both of which are not in the range of 50-150mPa·s, then by mixing Organic substances such as terpineol and ethanol, or inorganic powders below 1um such as lime mud and feldspar are added to it, and the viscosity of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com